Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine

38

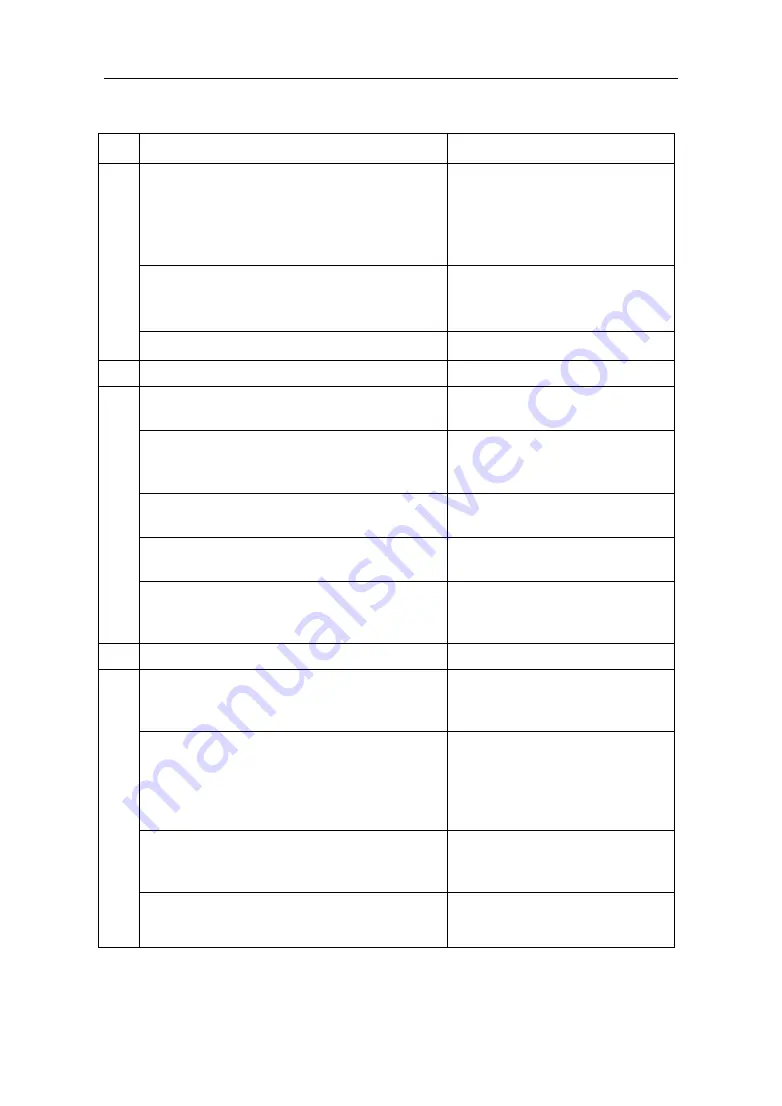

S/N

Cause

Troubleshooting

(4) Diesel fuel filter is clogged; the fuel

pressure in the fuel supply pump is

insufficient, the check valve of fuel supply

pump is fractured or worn; the spring is

fractured.

Check, clean, adjust or replace

it.

(5) Diesel fuel is not properly selected.

Refer to the local season

(ambient temperature) for fuel

grade selection.

(6) Advance angle of fuel injection is wrong.

Check and adjust it.

3

Air distribution system

(1) Air cleaner, air compressor of

supercharger and intercooler is not clean.

Dismantle and then clean them

(2) The external exhaust pipe does not meet

the requirements, and the back pressure of

exhaust system is too high.

Refer to the specifications and

design to arrange the exhaust

pipeline.

(3) Intake valves and exhaust valves are

leaked

Check and grind them.

(4) Timing of inlet valves and outlet valves is

wrong.

Check and adjust it.

(5) For the air starter, the inflation valve or

starting valve on the cylinder head are

leaked.

Dismantle and then grind them.

4

Others

(1) The compression pressure is insufficient

(compression ratio is wrong or the piston

rings are severely worn.)

Check, adjust or replace the

piston.

(2) Piston scuffs the cylinder lining, or other

wear parts failure.

Remove the cylinder head to

check inside surface of cylinder

liner or other wear parts. If

needed, timely repair or replace

it.

(3) Diesel engine can not sufficiently cool

down and therefore overheats.

Check the belt tension, each part

of cooling system, or remove

the scale.

(4) Bearings overheat, caused by poor

lubrication.

Repair or clean the lubricating

system.