5

Before beginning assembly, carefully read the

following information and instructions:

•

Assembly requires two persons.

•

Place all parts in a cleared area and remove the

packing materials. Do not dispose of the packing

materials until assembly is completed.

•

For help identifying small parts, use the PART

IDENTIFICATION CHART.

Note: Some small

parts may have been pre-attached for shipping. If

a part is not in the parts bag, check to see if it

has been pre-attached.

•

Tighten all parts as you assemble them, unless

instructed to do otherwise.

•

As you assemble the resistance system, make

sure all parts are oriented as shown in the draw-

ings.

The included Allen wrenches

and the follow-

ing tools (not included) are required for assem-

bly:

• Two adjustable wrenches

• One rubber mallet

• One standard screwdriver

• One Phillips screwdriver

• Lubricant, such as grease or petroleum jelly,

and soapy water.

Assembly will be more convenient if you have a

socket set, a set of open-end or closed-end

wrenches, or a set of ratchet wrenches.

Make Things Easier for Yourself

This manual is designed to ensure that the resist-

ance system can be assembled successfully by

most people. However, it is important to realize

that the versatile resistance system has many

parts and that the assembly process will take

time. Most people find that by setting aside plenty

of time, assembly will go smoothly.

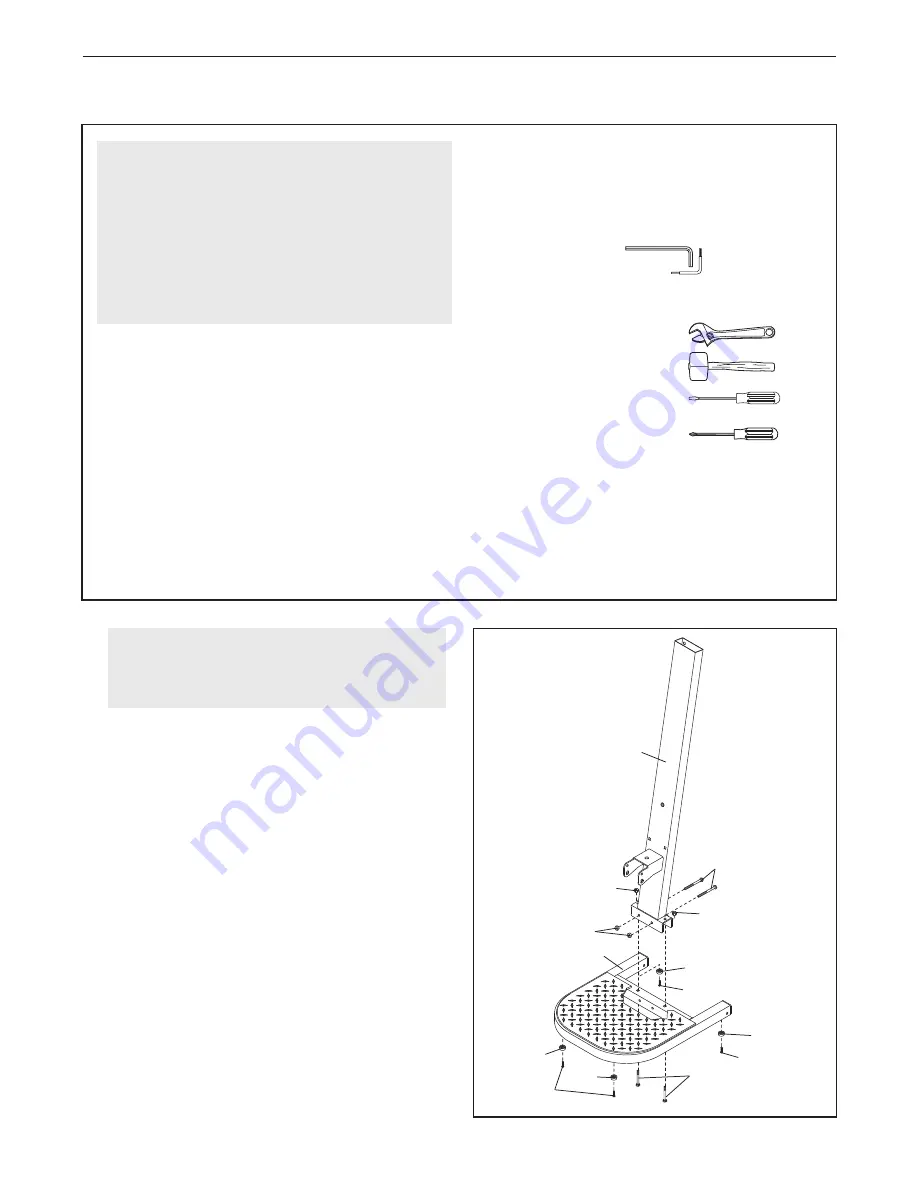

ASSEMBLY

1

1.

Attach two Plastic Feet (53) and two Large Plastic

Feet (9) to the Base (1) with four M4 x 16mm

Screws (62).

Attach the Upright (3) to the Base (1) with two

M10 x 66mm Carriage Bolts (83), two M10 x

72mm Bolts (64), and four M10 Nylon Locknuts

(76) as shown.

Note: This step will be easier if

the Upright and Base are tipped on their

sides.

Before beginning assembly, make sure that

you have read and understand the informa-

tion in the box above.

76

76

76

64

3

62

1

53

53

62

9

62

9

83