1.

Locate and open the parts bags labeled “FRAME

ASSEMBLY 1” and “FRAME ASSEMBLY 2.”

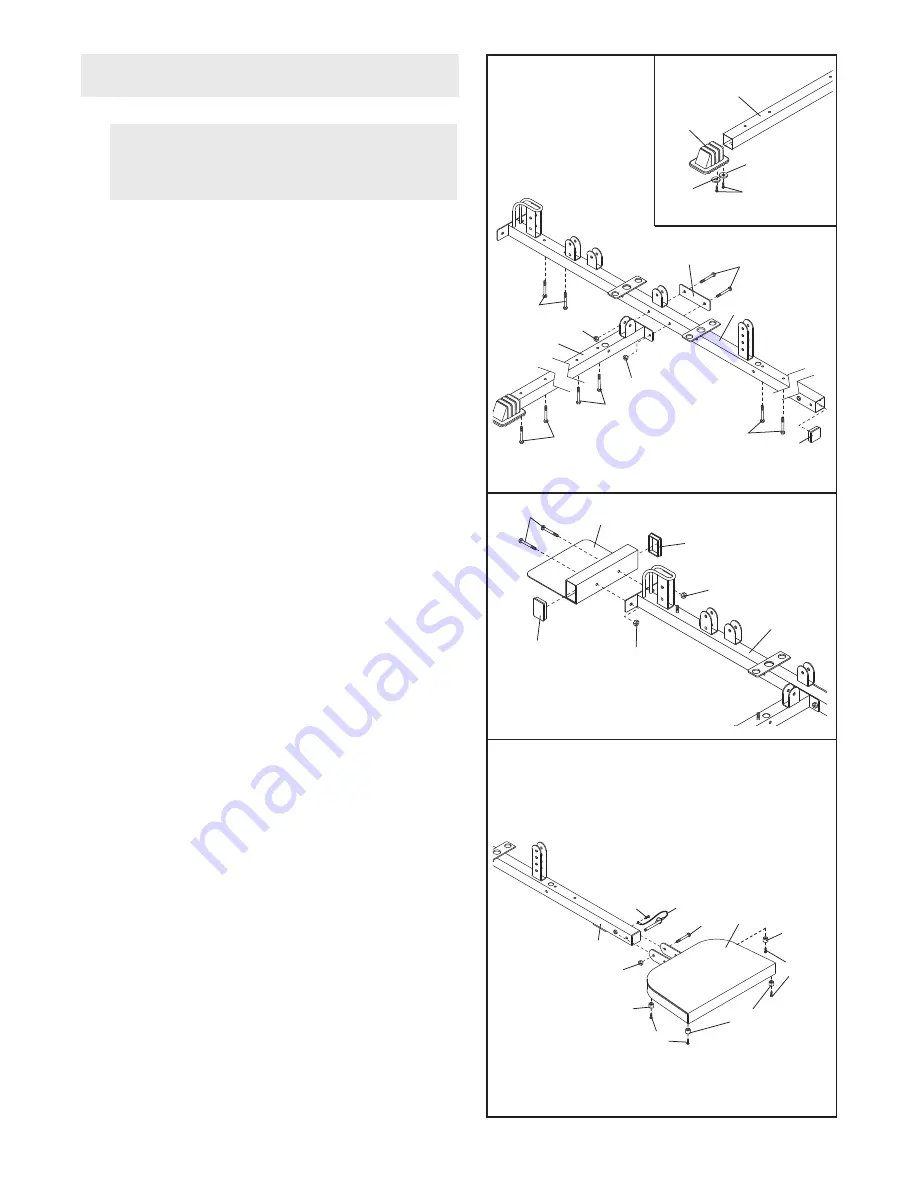

See the inset drawing. Attach the Base Cap (24) to

the Short Base (2) with two M4 x 20mm Self-tapping

Screws (14) and two M4 Washer (98).

Press a 50mm Square Inner Cap (105) into the

open end of the Long Base (106).

Insert eight M10 x 65mm Carriage Bolts (110) up

through the Long Base (106) and the Short Base (2)

as shown.

Note: It may be helpful to place tape

over the heads of the Carriage Bolts to hold

them in place.

Attach the Short Base (2) to the Long Base (106)

with two M10 x 70mm Bolts (85), the Long Frame

Plate (71), and two M10 Nylon Locknuts (87).

FRAME ASSEMBLY

6

Make sure that you understand all of the

information on page 5 before you begin

assembling the weight system.

1

85

87

105

106

71

2

87

2.

Press two 50mm x 75mm Inner Caps (58) into the

Foot Plate (53). Attach the Foot Plate to the Long

Base (106) with two M10 x 65mm Carriage Bolts

(110) and two M10 Nylon Locknuts (87).

3.

Attach the tether on the Pin w/Tether (112) to the

Long Base (106) with an M4 x 20mm Self-tapping

Screw (14).

Attach the four Knee Rest Bumpers (30) to the

Squat Knee Rest (41) with four M4 x 20mm Self-

tapping Screws (14).

Attach the Squat Knee Rest (41) to the Long Base

(106) with an M10 x 85mm Bolt (96) and an M10

Nylon Locknut (87).

Do not overtighten the Nylon

Locknut; the Squat Knee Rest must be able to

pivot.

3

106

112

87

14

96

41

30

30

30

14

14

110

110

110

110

2

87

87

58

58

110

53

106

14

24

98

98

2