27

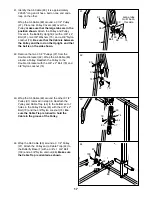

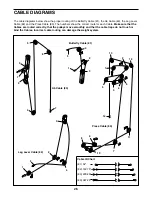

Slack can be removed form the Press Cable (80) by

moving the indicated “V”-Pulley (38) to one of the four

free holes in the Press Seat Frame (12). Remove the

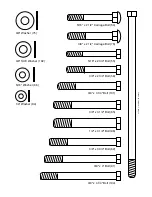

3/8” x 4 1/4” Bolt (104), 3/8” Washer (75), and 3/8”

Nylon Locknut (74) from the Press Seat Frame,

Pulley, and Long Cable Trap (50). Reattach the Pulley

and Long Cable Trap to the next hole with the Bolt,

Washer, and Nylon Locknut. Move the Pulley away

from the Leg Press Arm (22) one hole at a time, until

the Cable is tight.

Be sure the Long Cable Trap (50) is positioned to

hold the Press Cable (80) in the groove of the “V”-

Pulley (38).

43

37

37

43

Adjustment

Holes

74

74

44

44

79

79

75

104

22

12

50

38

74

80

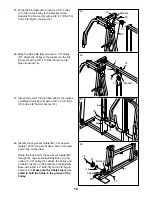

The Pulley Plates (43) have several sets of adjust-

ment holes. By moving one or both 3 1/2” Pulleys

(37) to a different set of holes, you will tighten the

cables.

To move a 3 1/2” Pulley (37), remove the 3/8” Nylon

Locknut (74) and the 3/8” x 2” Bolt (79) from the

Pulley, Cable Trap (44) and Pulley Plates (43). Re-

attach the Pulley and Cable Trap to the appropriate

adjustment hole in the Pulley Plates with the Bolt and

Nylon Locknut.

Note: Begin by moving one Pulley

to the second adjustment hole. If the cables are

still too loose, move the same Pulley to the third

hole. If additional adjustment is needed, move the

other Pulley until the cables are tight.

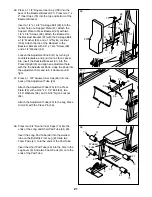

TROUBLE-SHOOTING AND MAINTENANCE

TIGHTENING THE CABLES

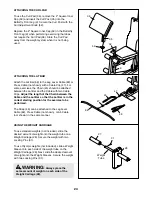

If a cable slips off the pulleys often, the cable may have become twisted. Remove the cable and re-install

it.

If the cables need to be replaced, see ORDERING REPLACEMENT PARTS on the back cover of this manual.

The type of cable used on the weight system can stretch slightly when it is first used. If there is slack in the

cables before resistance is felt, the cables should be tightened. Slack can be removed from the cables in two

different ways: