9

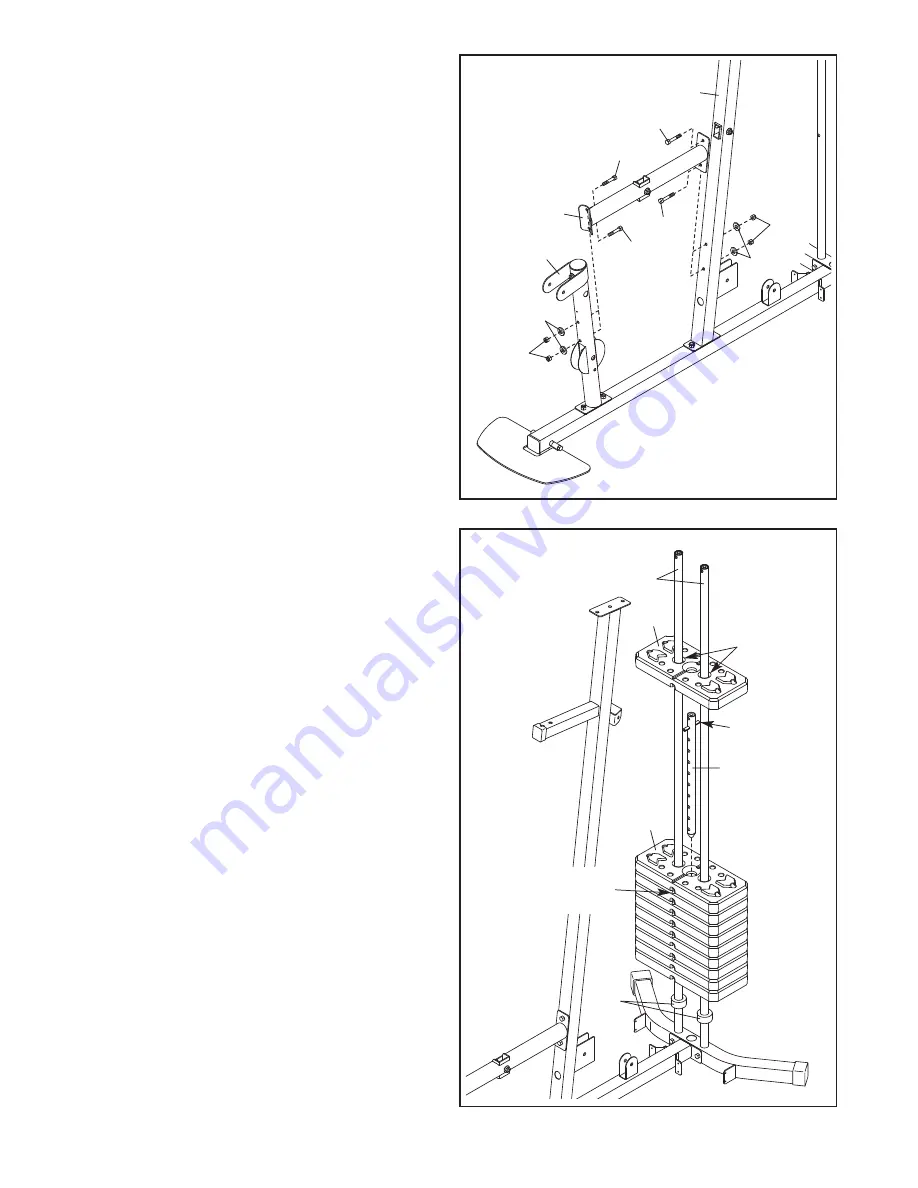

6. Slide the two Weight Bumpers (27) onto the

Weight Guides (21).

Orient nine Weights (22) so that the pin holes

are on the bottom as shown. Slide the Weights

onto the Weight Guides (21).

Insert the Weight Selector (24) into the nine

Weights (22).

Make sure that the pin on the

Weight Selector is oriented as shown.

Apply some of the included grease inside the

indicated holes in the remaining Weight (22).

Then, slide the Weight onto the Weight Guides

(21).

5

6

21

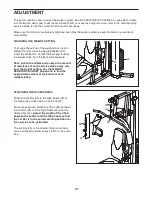

5. Attach the Seat Tube (6) to the Upright (3) with

two M8 x 65mm Bolts (68), two M8 Washers

(59), and two M8 Locknuts (58).

Do not tighten

the Locknuts yet.

Attach the Seat Tube (6) to the Front Leg (7)

in the same way.

7

6

3

58

59

68

68

68

68

59

58

27

22

22

24

Pin

Pin Hole

Grease

Summary of Contents for 6900 831.14922.1

Page 28: ...28 NOTES ...