7 Example applications

| Dual-channel safety door monitoring with proximity sensors, automatic reset and emergency stop

85

u-remote IP20 modules for functional safety manual

1484600000/04/06.2017

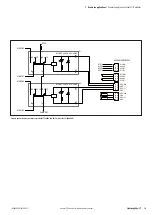

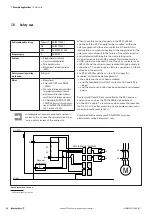

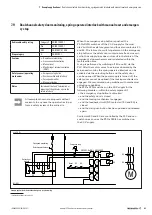

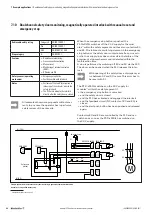

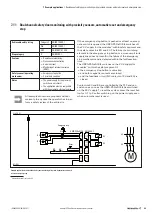

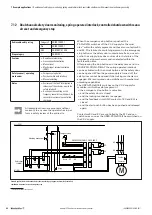

7.11 Dual-channel safety door monitoring with proximity sensors, automatic reset and emergency

stop

Achievable safety rating

Category 3

EN ISO 13849-1

PLd

EN ISO 13849-1

SIL 2

EN 62061/61508

Stop category

0

EN 60204-1

Features

–

Dual-channel monitoring

–

Cross-connection detection

–

Automatic reset

–

Monitoring of external contactors

(EDM)

Safety sensor/operating

mechanism

–

Emergency stop button

–

2 proximity switches

Notes

–

The power supply for the proximity

switches is not shown!

–

The application must be compatible

with the automatic start-up function.

All examples shown are proposals without

warranty. In any case the operator has to per-

form a safety review of the entire site.

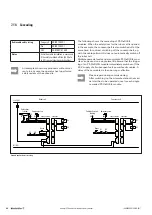

1.1

1.2

1.3

1.4

3.1

3.2

3.3

3.4

4.1

4.2

4.3

4.4

1.1

1.2

1.3

1.4

2.1

2.2

2.3

2.4

3.1

3.2

3.3

3.4

4.1

4.2

4.3

4.4

M

UR20-PF-O-xDI-SIL UR20-4DO-P

K4

K3

K4

K3

Reset

S1

S2

S3

L+(+24 V)

M (0 V)

K4

K3

Emergency stop

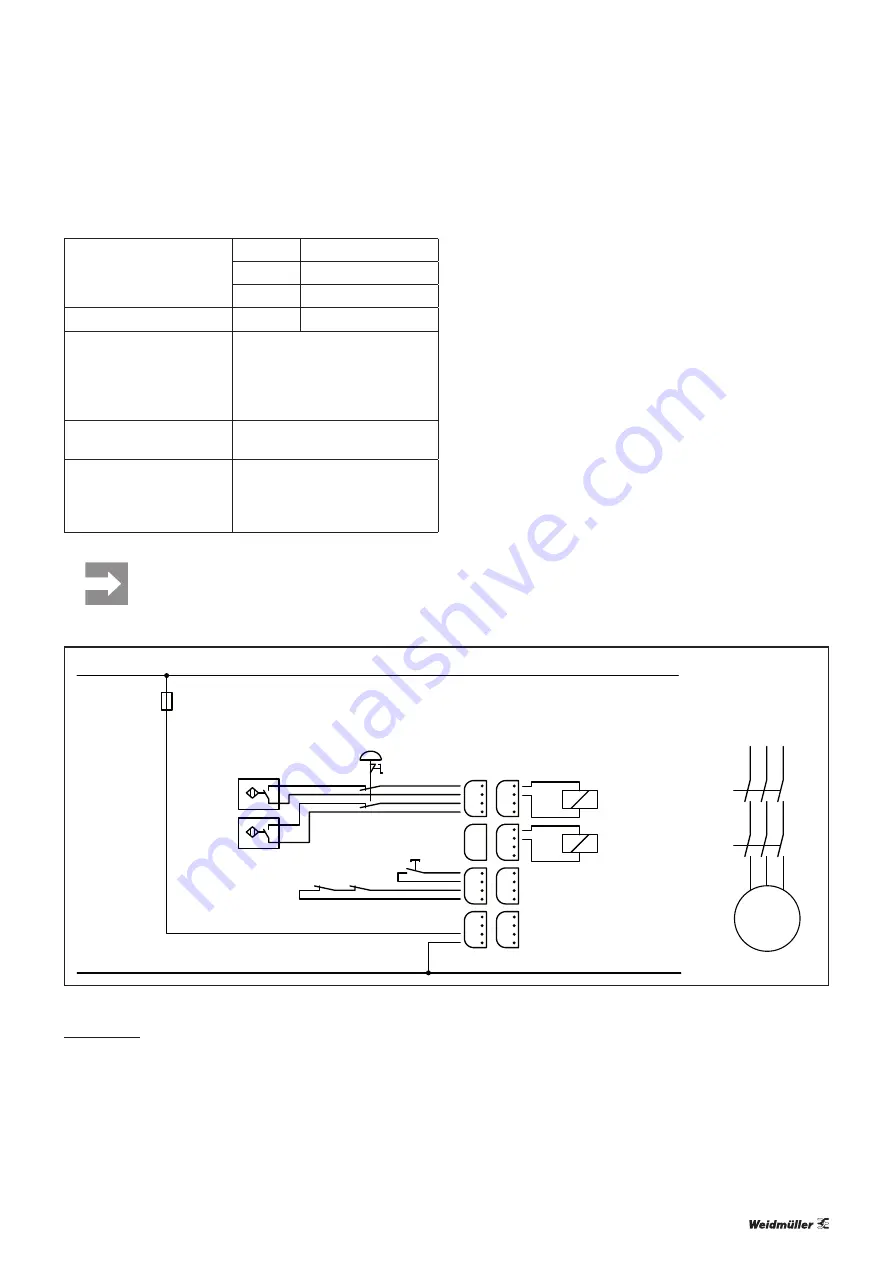

Example application for dual-channel safety door monitoring with proximity detectors, automatic

reset and emergency stop

1)

Switchable modules see section 4.3

If the emergency stop button is pushed or at least one mag-

netic switch is opened, the UR20-PF-O-xDI-SIL switches off

the 24 V supply for the

modules

1)

within safety segment and

thus also contactors K3 and K4. The failure of a switching

element in the emergency stop button or a cross-circuit in its

supply lines does not result in the failure of the emergency

stop mechanism and is detected within the fault-reaction

time.

The UR20-PF-O-xDI-SIL switches on the 24 V supply for

modules

1)

within the safety segment if

–

the emergency stop button is unlocked

–

and both magnetic contacts are closed

–

and the feedback circuit (NC contacts of K3 and K4) is

closed.

Contactors K3 and K4 are controlled by the PLC and can

switch on as soon as the UR20-PF-O-xDI-SIL has switched

on the 24 V supply. To reset the system,

press the reset but-

ton for 0.1 to 2 s after switching

on the power supply, even

when automatic reset is used.

Summary of Contents for UR20-4DI-4DO-PN-FSOE

Page 1: ...Remote I O system u remote IP20 modules for functional safety Manual Original Letʼs connect ...

Page 8: ...8 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 20: ...20 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 70: ...70 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 72: ...72 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 96: ...96 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 102: ...ANNEX A 6 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 103: ...ANNEX A 7 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 104: ...ANNEX A 8 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 105: ...ANNEX A 9 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 106: ...ANNEX A 10 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 107: ...ANNEX A 11 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 108: ...ANNEX A 12 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 109: ...ANNEX A 13 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 110: ...ANNEX A 14 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 111: ...ANNEX A 15 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 112: ...ANNEX A 16 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 113: ...ANNEX A 17 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 114: ...ANNEX A 18 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 115: ...ANNEX A 19 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 116: ...ANNEX A 20 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 117: ...ANNEX A 21 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 118: ...ANNEX A 22 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 119: ...ANNEX A 23 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 120: ...ANNEX A 24 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 121: ...ANNEX A 25 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 122: ...ANNEX A 26 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...

Page 124: ...A 28 1484600000 04 06 2017 u remote IP20 modules for functional safety manual ...