• Installation • Start-Up • Maintenance • Parts

3

Part No. 550-141-935/0602

Installation must comply with —

•

State, provincial and local plumbing, heating and

electrical codes.

•

Regulations of servicing utilities.

•

National codes where applicable.

Before selecting boiler location

1. Check for nearby connections to:

a. Fuel supply

b. Electrical power

c. System water or steam piping

d. Venting systems - see page 31

e. Combustion and ventilation air supply — see

"Provide combustion and ventilation air supply

openings" on page 4.

2. Check area around boiler. Remove any combustible

materials, gasoline and other flammable vapors and

liquids.

Failure to keep boiler area clear and free

of combustible materials, gasoline and

other flammable liquids and vapors can

result in severe personal injury, death and

substantial property damage.

1

Before installing boiler

Provide clearance around boiler

•

Provide minimum clearances to combustible materials:

1. Singlewall vent pipe – 18 inches.

2. Doublewall vent pipe – refer to vent pipe

manufacturer's recommendations for vent pipe

clearances.

3. Boiler top — 24 inches.

4. Boiler front — 48 inches.

5. Boiler flue — 9 inches.

6. Boiler rear — 9 inches.

7. Boiler sides — 6 inches.

•

Boiler may be installed on combustible flooring.

•

See pages 34 and 35 for boiler dimensions.

Flue pipe/breeching clearances take

precedence over jacket clearances.

•

Left side — for cleaning and tankless heater removal –

34 inches.

•

Allow sufficient space on remaining sides for cleaning,

servicing and burner installation. See burner literature

for length and recommended service clearances.

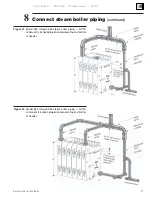

Figure 1

Boiler foundation

Table 1

Boiler foundation (see Figure 3)

Lay a foundation, if needed:

Floor construction and condition must be suitable for

weight of boiler when filled with water. See page 34 for

approximate boiler operating weight.

A level concrete or brick foundation (constructed per

Table 1 and Figure 1) is required when:

1. A floor could possibly become flooded.

2. Non-level conditions exist.