• Installation • Start-Up • Maintenance • Parts

31

Part No. 550-141-935/0602

13

Connect breeching and venting systems

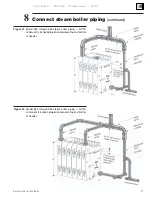

Figure 31

Stub vent – forced draft —

single boiler

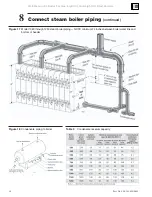

Figure 33

Conventional chimney –

balanced draft with barometric

draft control when required —

single boiler

Figure 32

Stub vent – forced draft —

multiple boilers

Figure 34

Conventional chimney –

balanced draft with barometric

draft control when required —

multiple boilers

General venting information

•

Model 80 boilers operate with positive overfire pressure. Adjust

damper assembly (see page 33) during burner start-up to achieve

0.1" W.C. positive pressure at damper sample hole.

Select type of venting system

Forced draft

Boiler, breeching and stub vent operate at positive pressure. Entire

system must be gas-tight to prevent leaks. Stub vent height must be

limited to prevent negative draft with 3-foot minimum stub vent

height above roof. See Figures 31 and 32.

Balanced draft

Boiler operates with positive pressure overfire. Chimney

may

provide

excess draft which may require a barometric draft control installed

and set to provide minimum draft to maintain 0.1" positive pressure

at flue collar. Minimum chimney height above roof is 3 feet. See

Figures 33 and 34.

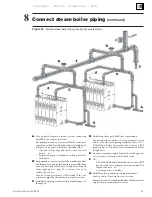

Construct metal breeching:

•

See Table 14 or Table 15 for minimum breeching diameter.

•

Select material type and thickness in compliance with local codes.

Conventional flue pipe should not be used as it could

leak flue gases and carbon monoxide emissions

through seams and joints, resulting in severe

personal injury or death.

•

Refer to ASHRAE Guide for chimney and breeching calculations

and construction and lining.

Long horizontal breechings, excessive number of

tees and elbows or other obstructions restricting

combustion gas flow can result in possibility of

condensation, flue gas leakage and carbon monoxide

emissions, causing severe personal injury or death.

Table 14

Minimum breeching diameter —

forced draft venting

Table 15

Minimum breeching diameter —

balanced draft venting