Boiler manual: • Installation • Start-Up • Maintenance • Parts

7

Part No. 550-110-275/1018

Set boiler in place

Do not raise or move assembled sections

using a jack or forklift. This could cause

the sections to shift, resulting in leaks.

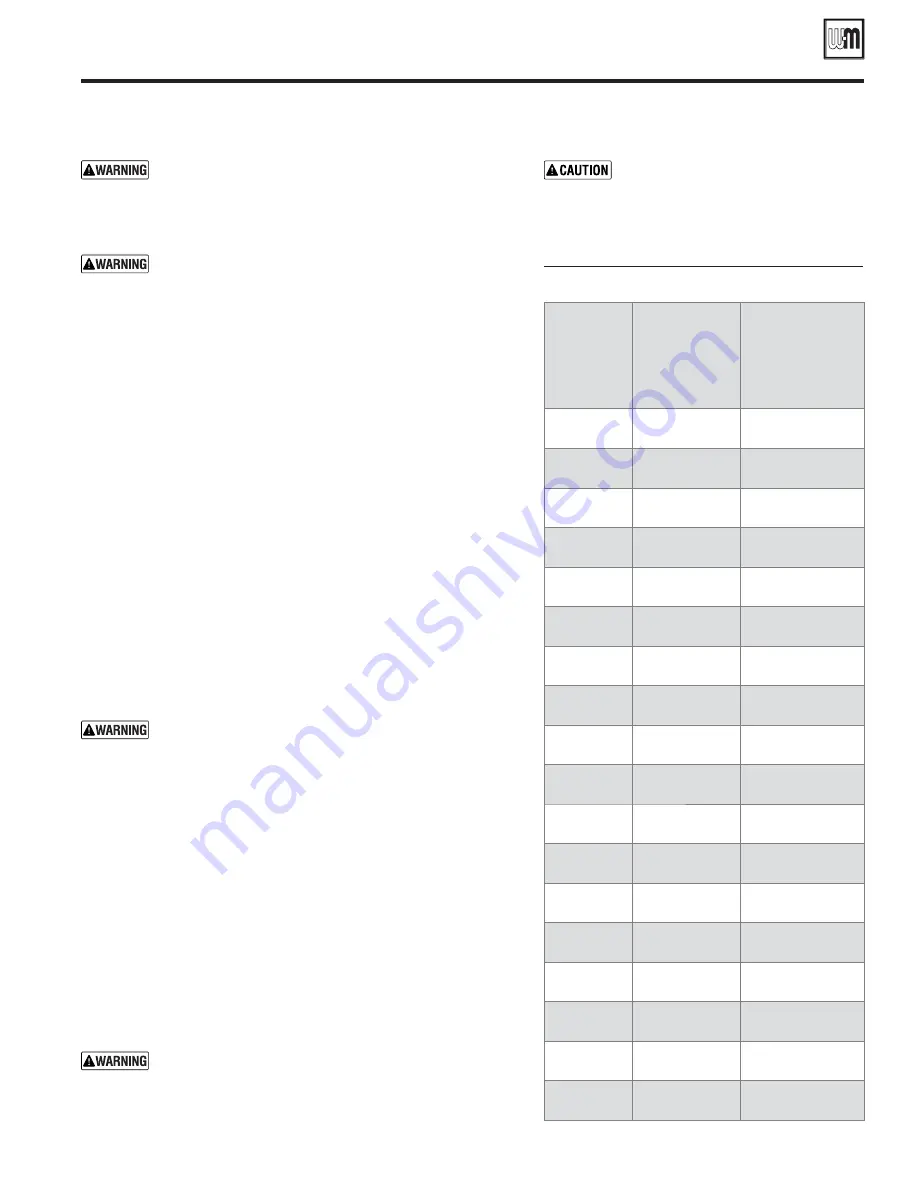

Figure 5

Section assembly lifting weights

Boiler

model

number

Approximate

lifting

weight

(pounds)

Minimum

sling length —

(from crane hook to

boiler lifting lugs)

894

8600

3' 6"

994

9500

3' 6"

1094

10300

4' 0"

1194

11200

4' 6"

1294

12000

5' 0"

1394

12800

5' 0"

1494

13700

5' 0"

1594

14500

5' 0"

1694

15400

5' 0"

1794

16200

5' 0"

1894

17100

5' 0"

1994

17900

5' 6"

2094

18700

5' 6"

2194

19800

7' 6"

2294

20600

7' 6"

2394

21500

7' 6"

2494

22400

8' 0"

2594

23200

8' 0"

Ensure the equipment and cables used for lifting are

designed to handle the load. See Figure 5 for approximate

weights of model 94 section assemblies. Failure to comply

can result in severe personal injury, death or substantial

property damage.

The boiler contains ceramic fiber and fiberglass materials.

Use care when handling these materials per instructions

on "Handling ceramic fiber and fiberglass materials,"

page 36 of this manual. Failure to comply could result

in severe personal injury.

For packaged boiler or assembled block

assembly:

1. Packaged boilers only — Remove top jacket panels. Set aside until

after boiler is piped.

2. Remove lag screws from shipping rails.

3. Remove boiler from skid. Cables are already attached to block as-

sembly. See Figure 5 for lifting weight.

•

Using crane – attach free end of cables to eye of crane.

• Using hoist – attach free end of cables to hoist. Raise boiler

off skid. Use pipe rollers under steel skid angles to roll boiler.

4. Place ¼" x 3" steel plates on floor or foundation, spaced 51 inches

apart, as shown in Figure 1, page 4.

5. Place boiler in final position. Place boiler on foundation (if used)

as shown in Figure 1, page 4.

6. Level boiler. Shim under legs if necessary.

7. Cut off cables.

Cables are not intended for long-term usage. Cables may

corrode inside boiler, weakening their lifting strength.

Failure to remove cables can result in severe personal

injury, death or substantial property damage.

8. Inspect block assembly for disjointed sections.

a. Check inside section assembly for any light passing through

unsealed areas.

b. Mark all unsealed areas.

c. At unsealed areas, check for:

• Damaged

gaskets.

•

Sealing rope not in place.

•

Loose bolts or nuts.

d. Correct all conditions and repeat step b. If unsealed areas still

exist, contact your Weil-McLain distributor or sales office

before continuing installation.

9. Check gas-tight seal of flue collector hood and cleanout plates.

Gas tight seal must be maintained to prevent possible flue

gas leakage and carbon monoxide emissions, resulting

in severe personal injury or death.

10. Proceed to "Perform hydrostatic pressure test," page 11.