Part number 550-100-305/0118

15

AquaBalance

TM

W

ALL

M

OUNT

GAS

-

FIRED

WATER

BOILER

—

Boiler Manual

4 Converting boiler to propane

continued

The jacket door must be in place during

operation.

DO NOT operate the boiler with

the jacket door removed except for inspection

and testing as directed in this manual.

Do not check for gas leaks with an open flame —

use bubble test. Failure to use bubble test or check

for gas leaks can cause severe personal injury,

death or substantial property damage.

6. Reinstall control module, reinstall screw to hold control

module securely in place

7. Reinstall jacket door, and secure with two (2) screws.

Mandatory control changes for fuel

conversion

8. Adjust parameter for the type of gas:

a. Put the boiler in standby mode.

b. Press the DHW buttons details 1 and 2 - Figure 76, page 60

for 10 seconds: the display shows “b01“ flashing.

c. Press the DHW buttons Figure 76, page 60 details 1 and 2

- to set parameter 00 (for use with natural gas) or 01

(for use with LP).

d. Press the Heating (+) button to scroll to Parameter “b04”.

e. Press DHW (-) to reduce the Maximum Blower

see Figure 123, page 97.

f. Press the (+) button to scroll to Parameter “b05”.

g. Repeat Step “e” above according to your boiler size.

h. Press the Heating (+) button to scroll to Parameter

“b06”.

i. Press DHW (-) to reduce the Minimum Fan Speed

,

see Figure 123, page 97:

j. Press the DHW buttons details 1 and 2 -

Figure 76, page 60 for 10 seconds.

k. The boiler will return to standby mode.

9. Turn on gas by opening gas valve, check for leaks and con-

tinue boiler start up and adjustments, staring on page 77.

10. Test ignition system safety shutoff, see page 78.

11. In USA Input rates are derated 4% for each 1000 ft. above

sea level, beyond 2000 ft. in accordance with National Fuel

Gas Code, ANSI Z223.1/NFPA 54 - latest edition, and/or

the Natural Gas and Propane Installation Code, CAN/CSA

B149.1.

12. Using a combustion analyzer insert probe into the flue

test point, check that the CO

2

content in the exhaust, with

the boiler operating at max. and min. firing rate, matches

that given in the technical data Figure 102, page 77 or Fig-

ure 105, page 78, for the corresponding type of gas.

DO NOT ATTEMPT TO MEASURE VALVE

OUTLET PRESSURE.

The valve could be

damaged by manometer fluid contamination.

Failure to comply could result in severe personal

injury, death or substantial property damage.

Perform Boiler Manual start-up

Follow all instructions in Boiler Manual to start-up

the boiler after converting for propane. Because the

boiler has been changed,

you must verify correct

operation, including checking combustion with

test instruments both at high fire and low fire as

described in the Boiler Manual, pages 76, 77 & 78

.

Check the correct ignition sequence of the boiler

after the conversion, as in page 86.

Failure to comply could result in severe personal

injury, death or substantial property damage.

Reinstall boiler jacket front door

Replace boiler jacket front door after servicing. The

boiler front door must be securely fastened to the

boiler frame to prevent boiler from drawing air

from inside the boiler room. This is particularly

important if the boiler is located in the same

room as other appliances. Failure to keep the door

securely fastened could result in severe personal

injury or death.

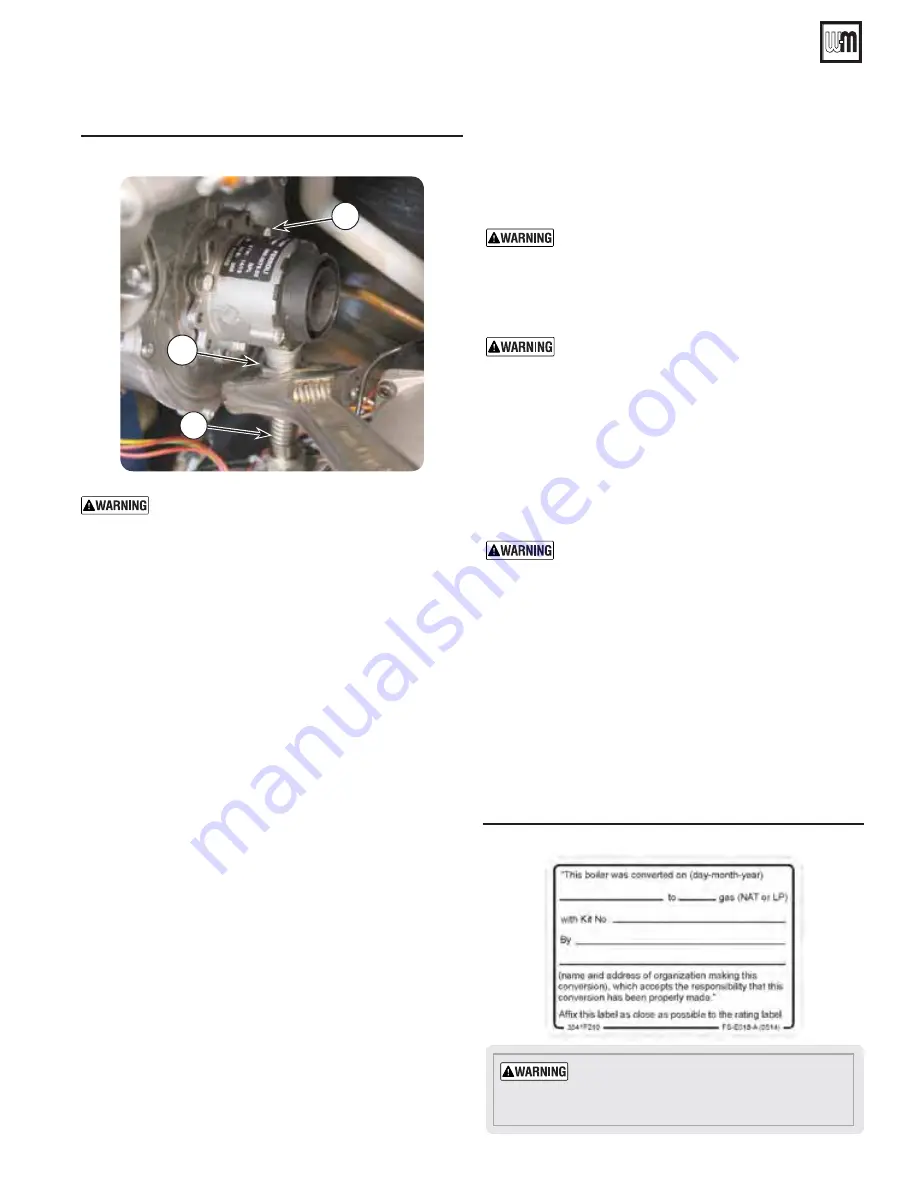

Apply installer conversion label

1.

Converting to propane firing: After installation is complete,

attach the propane conversion label (from kit) next to the

boiler rating label.

2. Contractor/installer is responsible for completing the in-

formation required on label (provided in kit) and attaching

installer conversion label next to the boiler rating label.

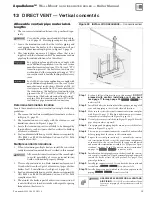

Figure 17

Gas pipe re-assembled to LP venturi fitting

Figure 18

Installer conversion label

A

3

5