Part number 550-100-305/0118

3

AquaBalance

TM

W

ALL

M

OUNT

GAS

-

FIRED

WATER

BOILER

—

Boiler Manual

1

Quick Start Guide

— using default settings

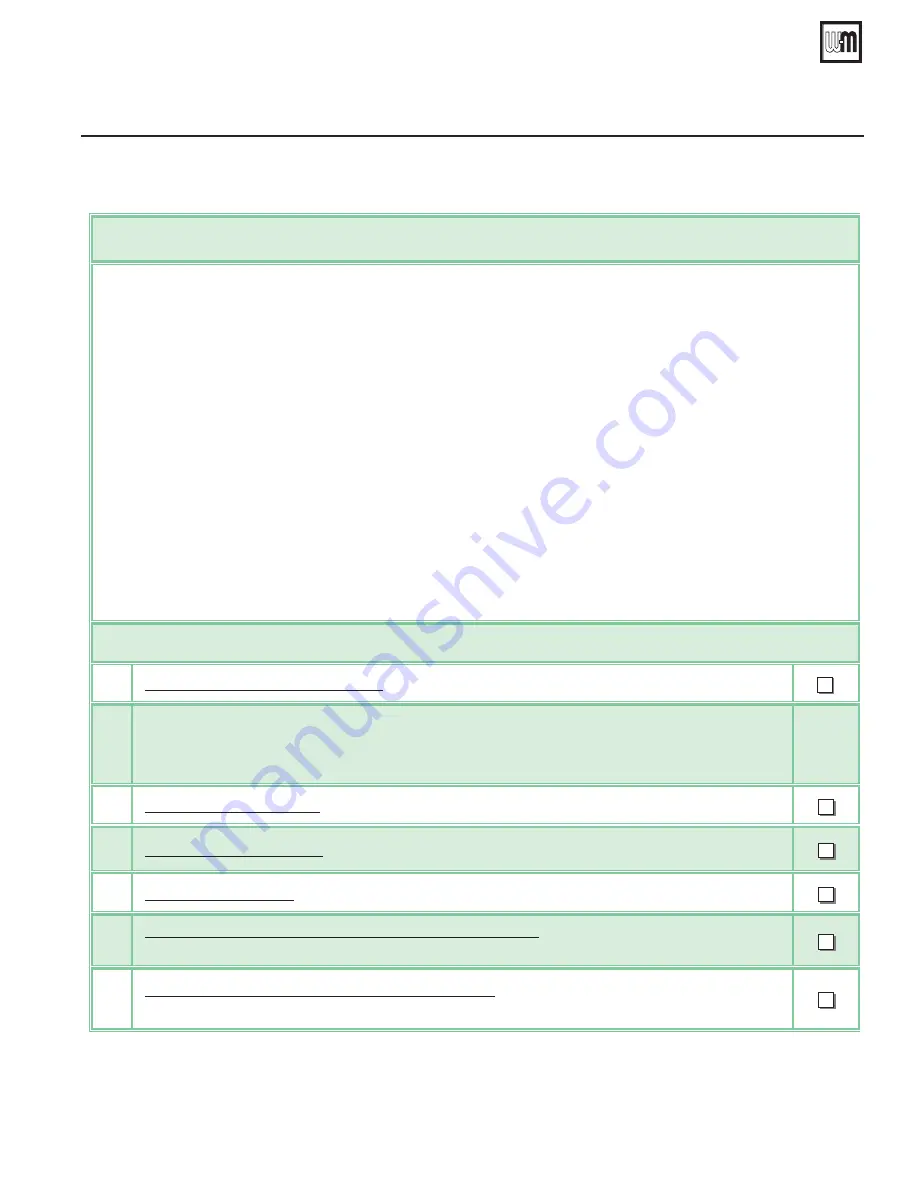

QUICK START GUIDE

After you have completed the installation of the Combi or Heating Only model by the instructions provided in

this manual, pages 5-71 insure the following first before you proceed:

All gas lines are connected and tested for leaks, and if the boiler is to operate on LP fuel, and the unit has been

converted properly from Natural gas to Liquefied Petroleum (Propane) gas and set up as directed in the boiler

manual.

All water piping is installed correctly and free of leaks with the proper accessories; proper sized expansion tank,

water feed valve adjusted, low water cut-off devices installed and tested, all operation control exterior to the boiler

installed such as thermostats, and zone control panels.

•

Sentinel X100 Inhibitor has been added and the water has been checked with the supplied test kit.

•

Condensate trap has been filled with water.

•

Electrical connection for the boiler is grounded and has correct polarity.

•

Venting and Intake Air Piping is all secure, sealed and installed as instructed in this boiler manual.

•

Central Heating only boilers, Outdoor sensor MUST be installed and connected to the boiler control.

(See page 51)

System start

1

Push eco / comfort / Power button;

to start boiler

2

NOTE: if A-16 error code is displayed (Central Heating Only boiler) when unit is powered up,

the outdoor sensor is not installed. Install outdoor sensor and push the reset button to reset

error code. A faulty outdoor sensor will give an “F-39” error code.

The Outdoor sensor must be installed unless specifically exempted in the Energy Act statement on page 131.

3

04 “shows on the display” (control software version)

4

FH “shows on the display”

(Blower /inducer operating in purge mode of combustion chamber and venting for 5 minutes).

5

With no “call for heat”

(current boiler water temperature will be shown in degrees F).

6

To Change “Central Heating water temperature set-point”

(from 68 F to 190 degrees F) use the bottom set

of “+” or “–” keys to raise or lower the set point temperature.

7

To change “Domestic water temperature set-point”

(Combi Boiler set from 104 F to 131 degrees F )

NOTE: Insure that the operating temperature is at a safe set-point temperature. Use the top set of “+” or “–” keys to raise or lower the set point.

Figure 1

Quick Start Guide -

Default control settings (see instructions and figures on pages 60-65).