Part number 550-110-260/0107

51

GOLD CGs Gas-Fired Water Boiler — Boiler Manual

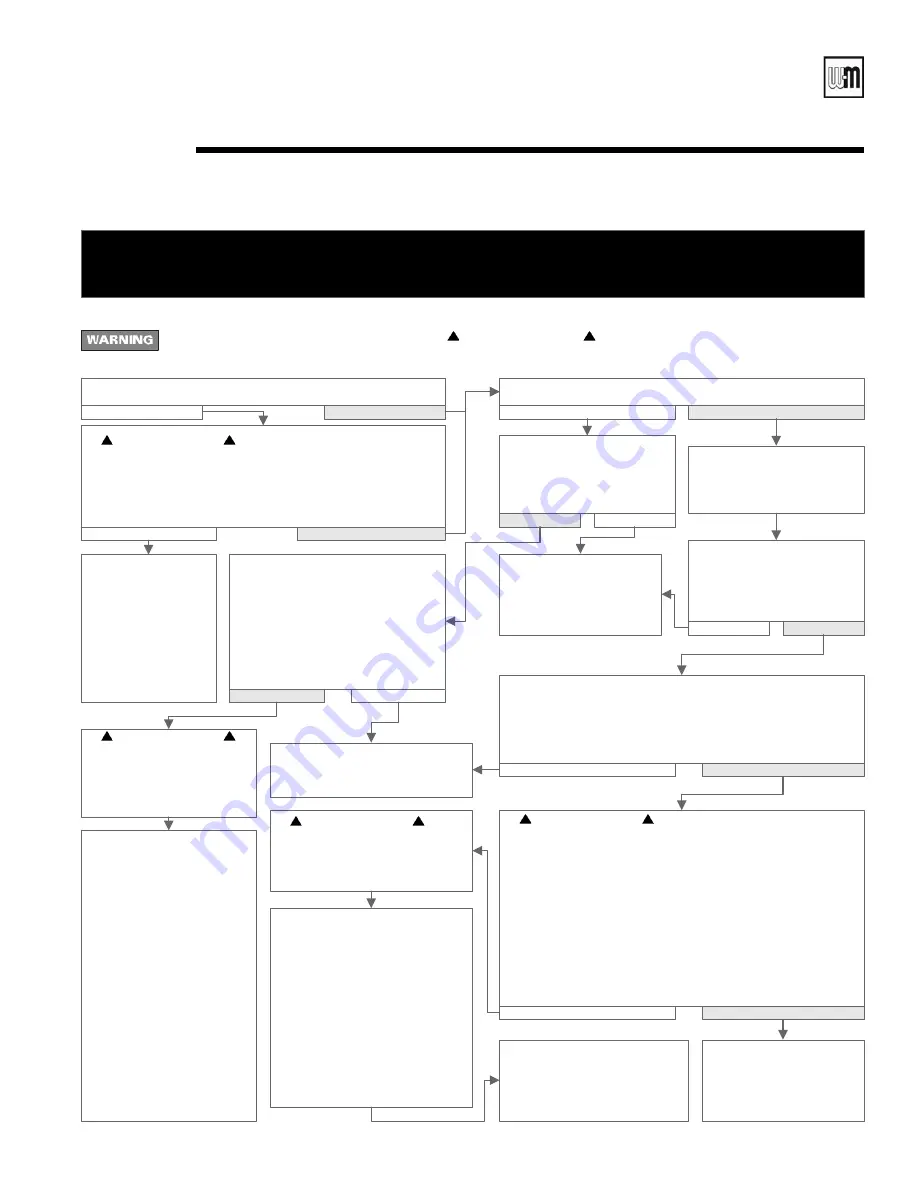

Troubleshooting — control module lights

(cont.)

11d

•

TURN OFF POWER

to

boiler at service switch or

breaker.

• Remove air inlet box cover (see

Figure 27

, page 56 for location).

• Verify inlet gas pressure at gas

valve:

Natural gas

— 5.0" w.c. min/14.0"

w.c. max

Propane

— 11.0" w.c. min/14.0"

w.c. max

Is gas present at gas valve inlet and

within above range?

CHART 5

—

FLAME

light flashing and

POWER

light on steady

ALSO

— Troubleshooting failure to establish

main flame

Electrical shock hazard — Wherever you see

TURN OFF POWER

, follow the instructions. Failure to follow

instructions could result in severe personal injury, death or substantial property damage.

No

Yes

• Is pilot flame visible through inspection port?

• Are main manual shutoff valve and boiler gas valve open?

No

Yes

•

TURN OFF POWER

to boiler at service switch or breaker.

• Open main manual shutoff valve and boiler gas valve (per

Operating instructions

in this manual). Wait at least 45

seconds.

• Turn on power at service switch or breaker. Allow boiler to cycle.

Does

FLAME

light flash now?

No

Yes

• Boiler should be in

normal operating

sequence.

• Observe operation

until thermostat is

satisfied and blower

has completed its

post-purge cycle.

• Make sure ground wire

terminal is securely fastened

to control module mounting

screw.

• Check the voltage across

terminals

"C"

and

"A"

of the

gas valve (see

Table G

,

page 33).

Is 24 VAC present there?

No

Yes

• Check the voltage across

terminals

"B"

and

"A"

(see

Table G

, page 33) of the

gas valve.

Is 24 VAC present there?

No

Yes

No

Yes

• Contact gas supplier to correct

pressure or gas supply.

• If the wiring from the

control module to gas

valve is intact, replace the

control module.

• Retest.

•

TURN OFF POWER

to boiler at service switch or breaker.

• Check flame signal — Detach sense lead from igntion control

(

Figure 25, item 8

, page 46

).

• Connect

negative

lead of MICROAMMETER to control sense

terminal (

Figure 25, item 8

, page 46

). Connect positive lead of

MICROAMMETER to sense wire.

• DISCONNECT

red

wire connected to terminal

"B"

(see

Table G

, page 33) of the gas valve.

• Turn on power to boiler and allow to cycle. As soon as pilot is

burning, the MICROAMMETER should read at least 1.0

microamp.

Is flame signal at least 1.0 microamp?

No

Yes

• If the wiring from the

control module to gas

valve is intact, replace the

control module and retest.

• Verify inlet gas pressure at gas valve:

Natural gas

— 5.0" w.c. min/14.0" w.c. max

Propane

— 11.0" w.c. min/14.0" w.c. max

Is gas present at gas valve inlet and within above range?

No

Yes

•

TURN OFF POWER

to

boiler at service switch or

breaker.

• Remove air inlet box top

(see

Figure 27

, page 56 for

location).

• Verify pilot gas line is not

kinked, obstructed or damaged

and is correctly attached to

pilot and gas valve.

• Verify pilot ignition electrode,

electrode ceramic and spark

lead wire from control are in

good condition. Spark gap

should be approximately 1/8".

• Correct any above problems,

replacing pilot if burner or

wiring is damaged.

• Reinstall air box top to operate

boiler for retest after any

changes or corrections.

• If none of the above corrects

problem, then replace the

control module, reinstall air box

top, and retest.

• Verify pilot burner is securely

attached to pilot bracket, bracket

is securely attached to cross tie,

and there is no corrosion on the

parts which would affect the

ground path for flame sense.

• Verify that pilot flame rod, flame

rod ceramic and lead wire from

control module to flame rod are in

good condition.

• Correct any above problems,

replacing pilot if burner or wiring

is damaged.

• If none of the previous steps

(including replacing pilot)

corrects problem, then replace

the control module, reinstall air

box cover and retest.