Part number 550-110-260/0107

5

GOLD CGs Gas-Fired Water Boiler — Boiler Manual

11d

Troubleshooting — control module lights

(cont.)

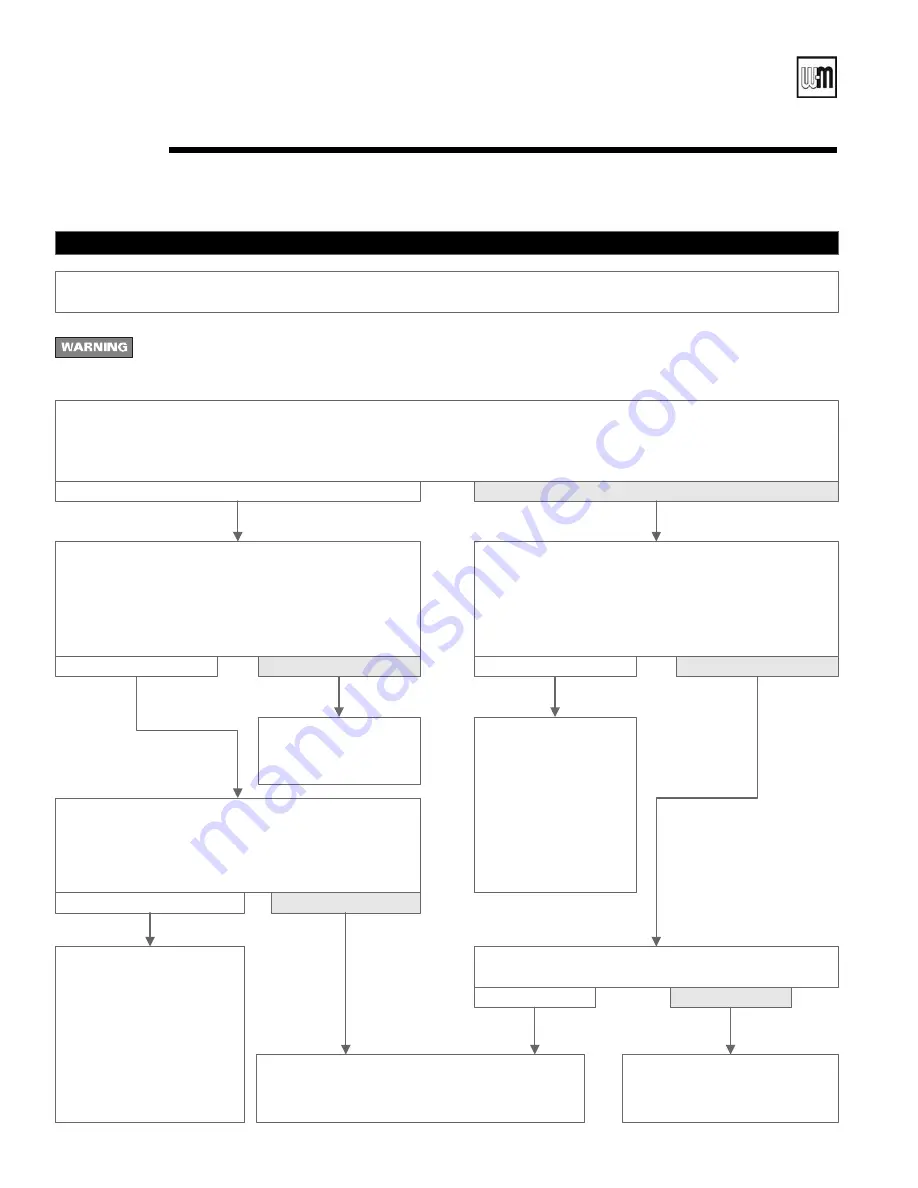

CHART 6

—

PRESS SWITCH

light flashing and

POWER

light on steady

Electrical shock hazard — Wherever you see �

TURN OFF POWER

�, follow the instructions. Failure to follow

instructions could result in severe personal injury, death or substantial property damage.

— Usually indicates pressure switch opened during run cycle —

— May also be caused by wind gusts in excess of 31 mph for non-direct vent sidewall-vented boilers —

• Boiler should be in

normal operating

sequence.

• Observe operation until

thermostat is satisfied

and inducer has

completed its post-

purge cycle.

• Remove one of the wires connected to the pressure

switch.

• Check continuity across the switch terminals.

Does the ohmmeter indicate the switch is closed?

• Inspect and check wire

harness from control

module to pressure switch.

• Reseat connector in control

module receptacle.

• If harness is intact and

properly seated, but

problem persists, replace

control module.

• Retest.

• Check air pressure switch per manual Section 11.

• Replace if necessary. Retest.

• Replace inducer

assembly.

• Retest.

No

Yes

• Remove

INDUCER

plug (

Figure 25, Item 6

, page 46

)

from plug receptacle of control module.

• Place voltmeter leads across the

120 VAC N

and

120 VAC H

pins of the

INDUCER

receptacle (left column

center and right column bottom pins).

Does the voltmeter indicate

120 VAC

?

No

Yes

Are vent or combustion air passages blocked?

No

Yes

• Clear passages and recycle

boiler.

• Recheck boiler operation.

• Wait 5 minutes.

Is

PRES SWITCH

light flashing?

• Reset boiler control by turning off power at service switch or turning down thermostat for at least 45 seconds.

• Thermostat should call for heat and appropriate zone valves open.

Does blower motor operate?

No

Yes

No

Yes