4

apply to installation of solid-state programmable control devices. In addition,

these precautions conform to the guidelines for installation of Controllers as

recommended in the NEMA ICS 3-304 Control Standards.

Programming

Considerations

To conform with ICS Safety Recommendations, checks should be placed

in the controller to ensure that all writable registers that control critical

parts of plant or machinery have limit checks built into the program, with

an out-of-limit safe shut down procedure to ensure safety of personnel.

ICS 3-304.81 Safety Recommendations:

Consideration should be given to the use of an emergency stop function, which is independent of the programmable

controller.

Where the operator is exposed to the machinery, such as in loading or unloading a machine tool, or where the machine

cycles automatically, consideration should be given to the use of an electromechanical override or other redundant means,

independent of the programmable controller, for starting and interrupting the cycle.

If provision is required for changing programs while the equipment is in operation, consideration should be given to the

use of locks or other means of assuring that only authorized personnel can make such changes.

These recommendations are intended as safeguards against the failure of critical components and the effects of such

failures or the inadvertent errors that might be introduced if programs are changed while the equipment is in operation. *

z

The ICS 3-304.81 Safety Recommendations are reproduced by permission of the National Electrical

Manufacturers Association from NEMA ICS 3-304

2.3 Communications Connections

The ports as you look at the back of the case, are the ports for connecting to a PLC or some external

device (Controller Connectors).

2.3.1 Connector COM1 [RS232], COM2 [RS232]

Cable

Requirements

Different cables are required for various devices.

Caution

Restrict cable length to less than 500’ (150m) for RS485/422 devices and

50’ (15m) for RS232 devices to avoid communications problems.

The COM light on the front of the MT-600/8000 will turn on with each

Ethernet communication.

Shielded cable must be used for long lengths or cables run in an electrically

noisy environment.

Do not run cables next to AC power lines or near sources of electrical noise.

Be sure that the cable ends have been inserted all of the way into mating

connectors and are secure

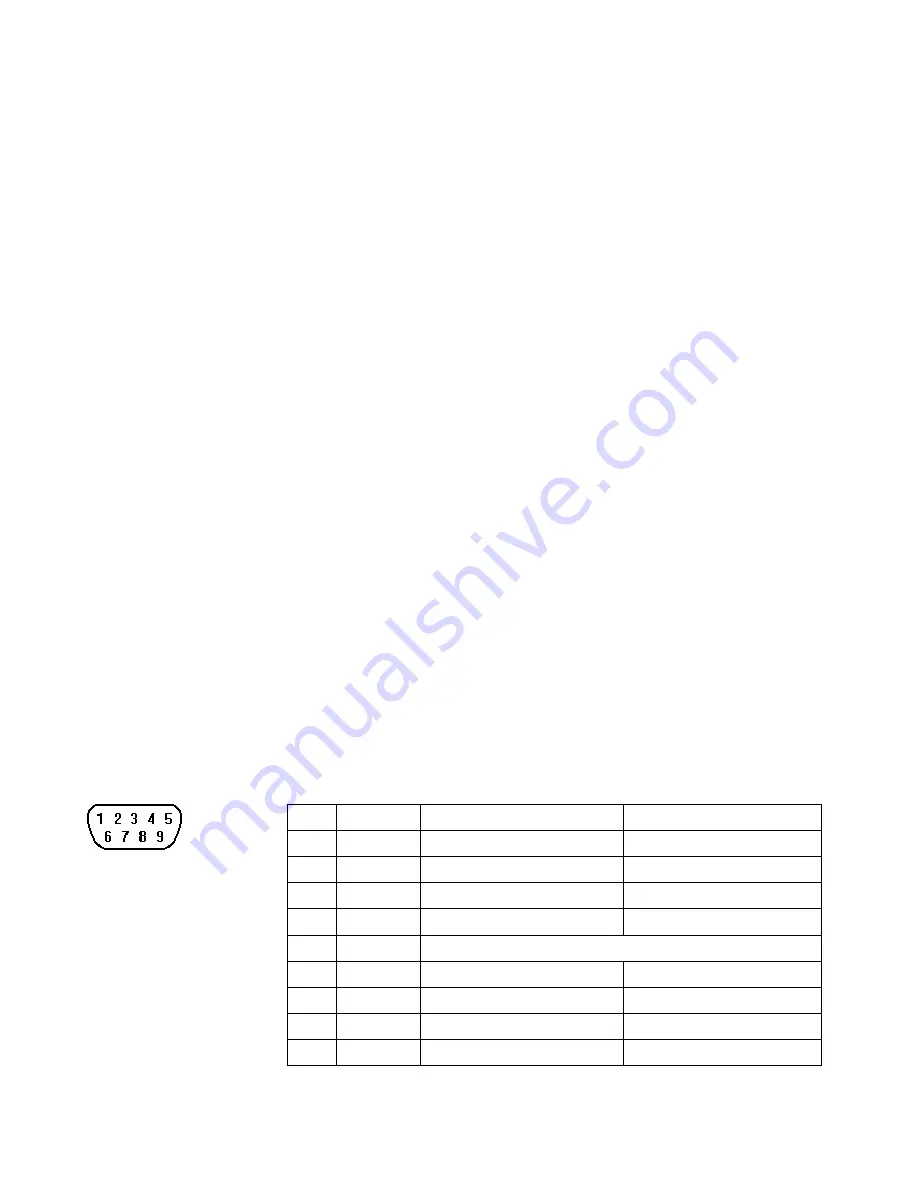

Pin assignment of the 9 Pin, Male, SUB-D, COM1 [RS-232] and COM2

[RS-232] Port.

Pin Designations

COM1 [RS-232]

COM2 [RS-232]

Pin# Symbol

COM1 [RS232]

COM2 [RS232]

1 Not

used

2 RxD Received

Data

3 TxD Transmitted

Data

4 TxD

Transmitted

Data

5 GND

Signal

Ground

6 RxD

Received

Data

7

RTS

Ready to send output

8

CTS

Clear to send input

9 Not

used