6

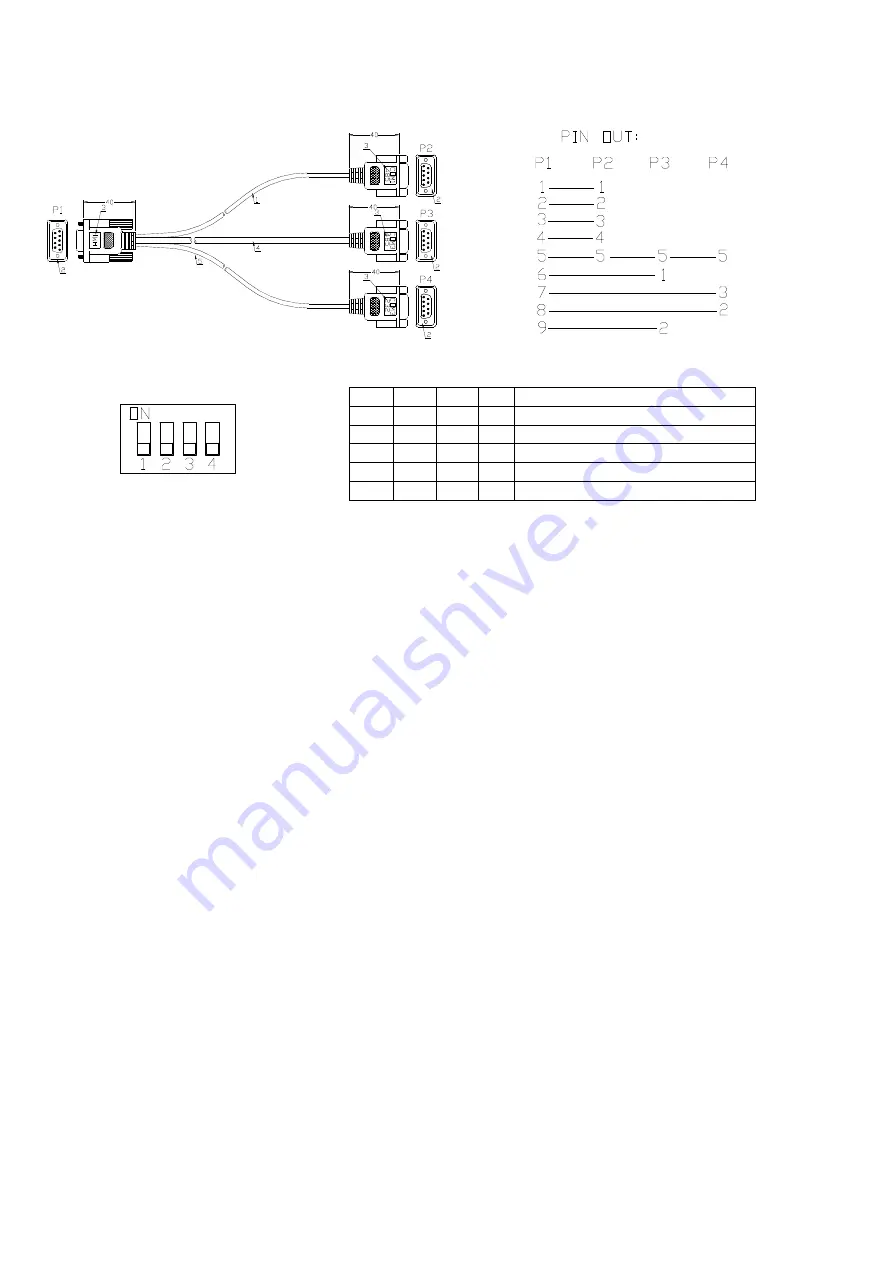

MT8-COM3/RZC004850

5

9

1

6

1

5

6

9

1

5

6

9

5

9

1

6

2.3.5 Dip Switch

2.4 Limited Liability Warranty

Weintek products include the isolated power supply are covered by a limited liability warranty from

defects in material and workmanship. This warranty does not apply :

(a) if, in the judgment of Weintek, the product fails due to damage from shipment, handling, storage, accident

(natural and man-mad) ;

(b) if the product fails due to misuse, including but not limit to incorrect set-up and wiring, current leakage

from machine platform and incorrect input power ;

(c) if the product has been maintained in a manner not conforming to product's instructions or has been

modified in any way,

(d) if the serial number has been defaced or removed.

2.5 CE Requirements

EU directives that apply to the MT-600/8000 Series:

EMC Directive (2004/108/EC) electromagnetic emissions and immunity.

UL508

(

ISBN 0-7629-0404-6

)

machine safety for use in Pollution Degree 2 Environment.

MT600 products will be CE-marked to indicate compliance with the EMC Directive.

The MT-600/8000 Series has been designed to operate satisfactorily in electromagnetic noise (immunity) and

without emitting high levels of electrical noise into the environment (emission). The units are designed to

meet European Community standards when installed per the wiring instructions in this manual.

Compatibility

Standards

The MT-600/8000 has been designed to meet electromagnetic compatibility for

industrial environments.

EN 55022: 1998+A1: 2000+A2: 2003 Class A

EN 61000-3-2: 2000+A2: 2005

EN 61000-3-3: 1995+A1: 2001

EN 55024: 1998+A1: 2001+A2: 2003

SW1 SW2 SW3 SW4 Mode

ON

OFF OFF OFF Reserve

OFF

ON

OFF OFF Hide MT8000 System Setting Bar

OFF OFF ON

OFF Reserve

OFF OFF OFF ON Front Panel Power Switch

enable

OFF OFF OFF OFF Normal