- 9 -

2. Operating procedure:

Reset the circuit breaker on the switchboard, then the welder’s indicator lamp will turn on,

and the cooling fan will spin. Press on the “Inch feeding” button on the feeder’s controller,

the feeder begin to feed wire. Preset the process parameters by regulating the controller,

tuning the knob, and flipping the switch to proper location on the front panel of the welder.

When the torch switch is pulled, the feeder start to feed wire, and CO

2

will blow out of the

nozzle, therefore it can be used for welding. Operators can select parameters from table

listed below. Be sure to turn off the valve of gas bottle and unplug the power cord while

stop welding.

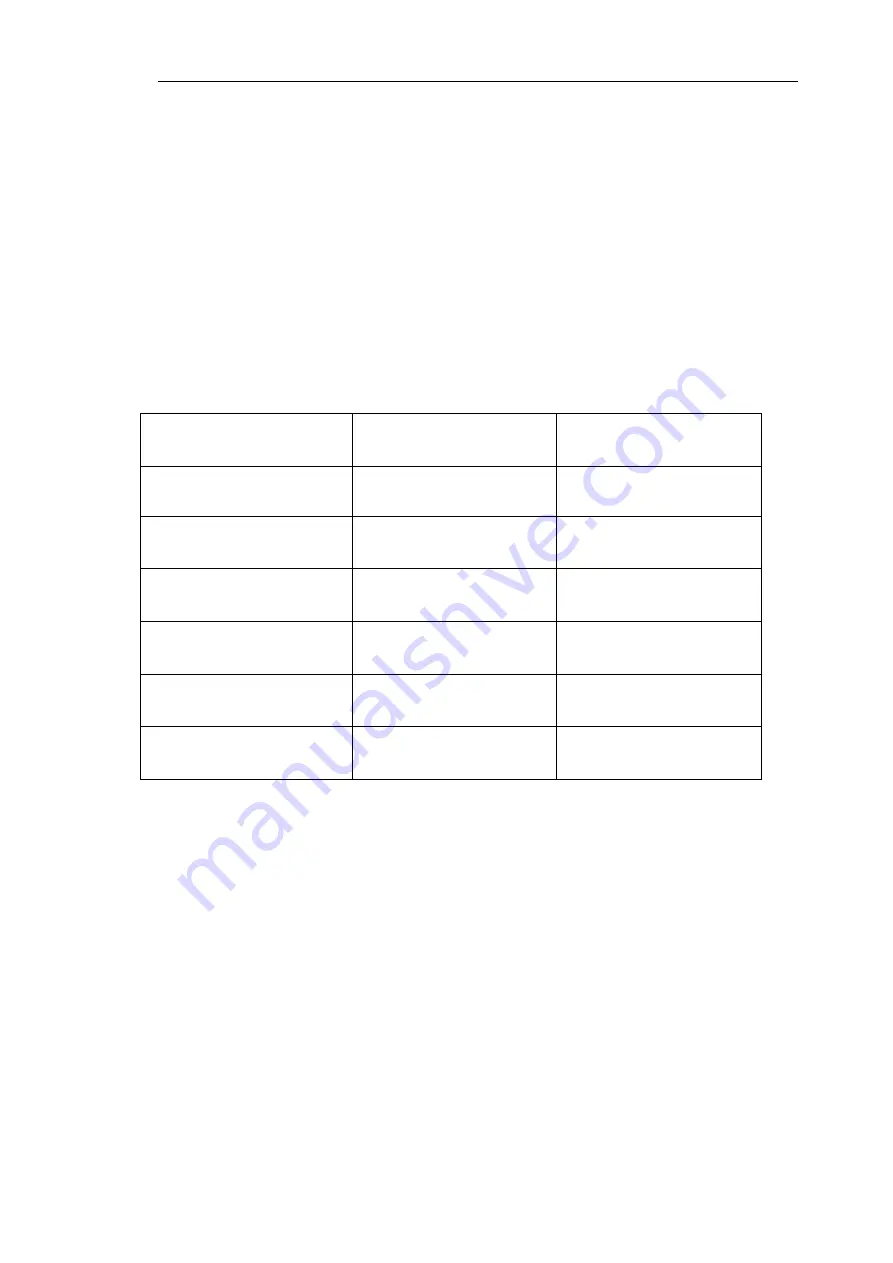

Welding current (A)

Welding voltage (V)

Suitable wire (mm)

60~80

17

~

18

Ф1.0

80~130

18

~

21

Ф1.0

、

Ф1.2

130~200

20

~

24

Ф1.0

、

Ф1.2

200~250

24

~

27

Ф1.0

、

Ф1.2

250~350

26

~

32

Ф1.2

、

Ф1.6

350~500

31

~

39

Ф1.6

Table 4: Suggest welding parameters for selected wire