Installation and operating instruction

Oil burner WL5-PB-H purflam®

10 Troubleshooting

83242002 1/2019-03 La

57-76

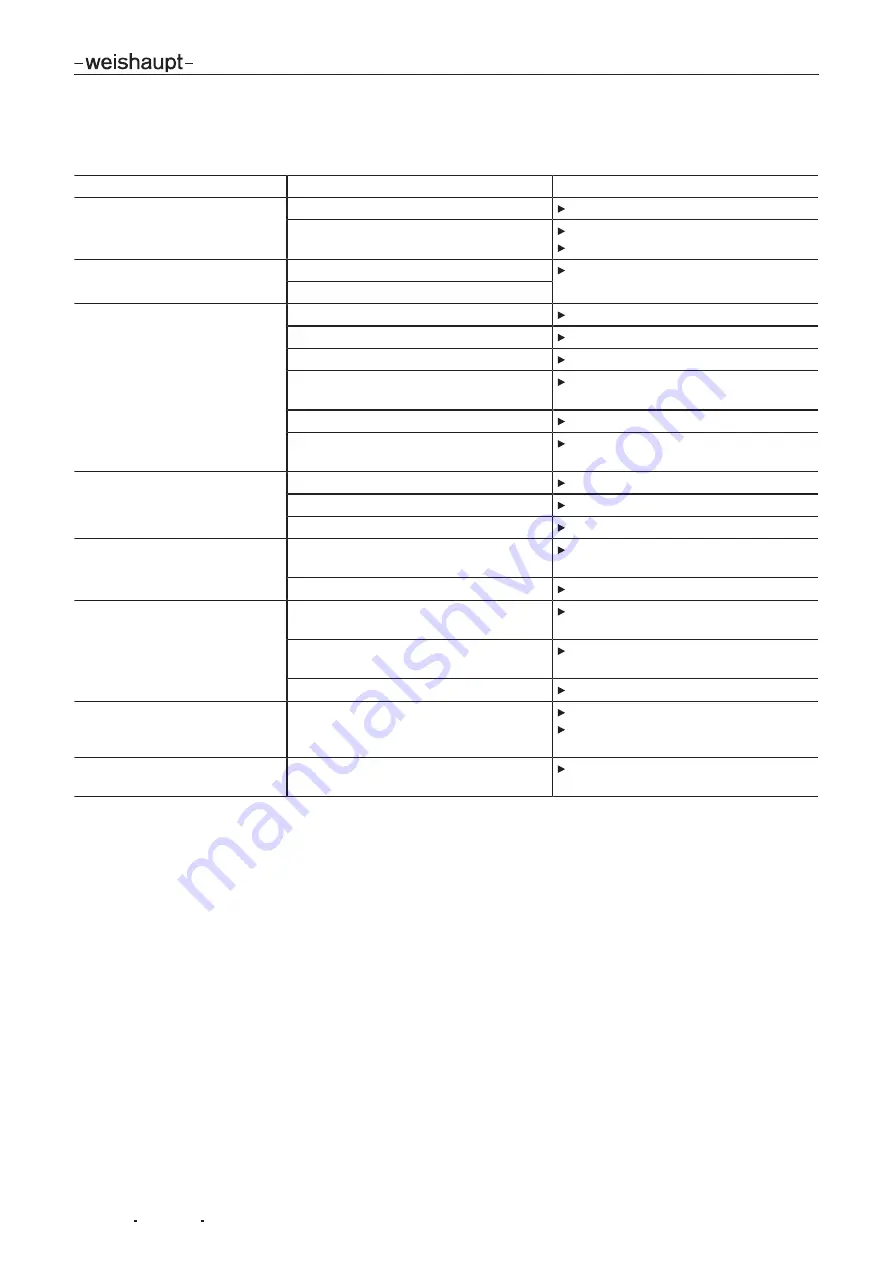

10.2 Operating problems

The following faults must only be rectified by qualified personnel:

Observation

Cause

Rectification

Oil pump makes severe mech-

anical noise

Oil pump sucks air

Ensure oil supply is tight

Suction resistance in oil line too high

Clean filter

Check oil supply

Oil nozzle atomisation uneven

Nozzle blocked/soiled

Replace nozzle [ch. 9.4]

Nozzle worn

Flame tube/air nozzle has heavy

soot deposit

Oil nozzle defective

Replace nozzle [ch. 9.4]

Mixing head set incorrectly

Set mixing head [ch. 9.10]

Incorrect combustion air quantity

Adjust burner

Boiler room ventilated insufficient

Ensure sufficient boiler room ventila-

tion

Wrong oil nozzle

Check nozzle type

Recirculation aperture too small

Increase recirculation aperture

[ch. 9.11]

Combustion pulsating or burner

booming

Mixing head set incorrectly

Set mixing head [ch. 9.10]

Incorrect combustion air quantity

Adjust burner

Wrong oil nozzle

Check nozzle type

CO content too high

Nozzle distance too big

Check nozzle distance, adjust if

necessary [ch. 9.10]

Fan speed too low

Increase fan speed

Stability problems

Nozzle distance incorrect

Check nozzle distance, adjust if

necessary [ch. 9.10]

Recirculation aperture too big

Reduce recirculation aperture

[ch. 9.11].

Fan speed too high

Reduce fan speed

Burner pulsating at START

Combustion chamber resistance too

high (e. g. condensing boiler)

Check installation

If necessary optimise start behaviour

[ch. 9.17]

Flue gas noise emission too

high

Unsuitable or no flue gas sound ab-

sorber installed

Check or fit flue gas sound absorber