15

3

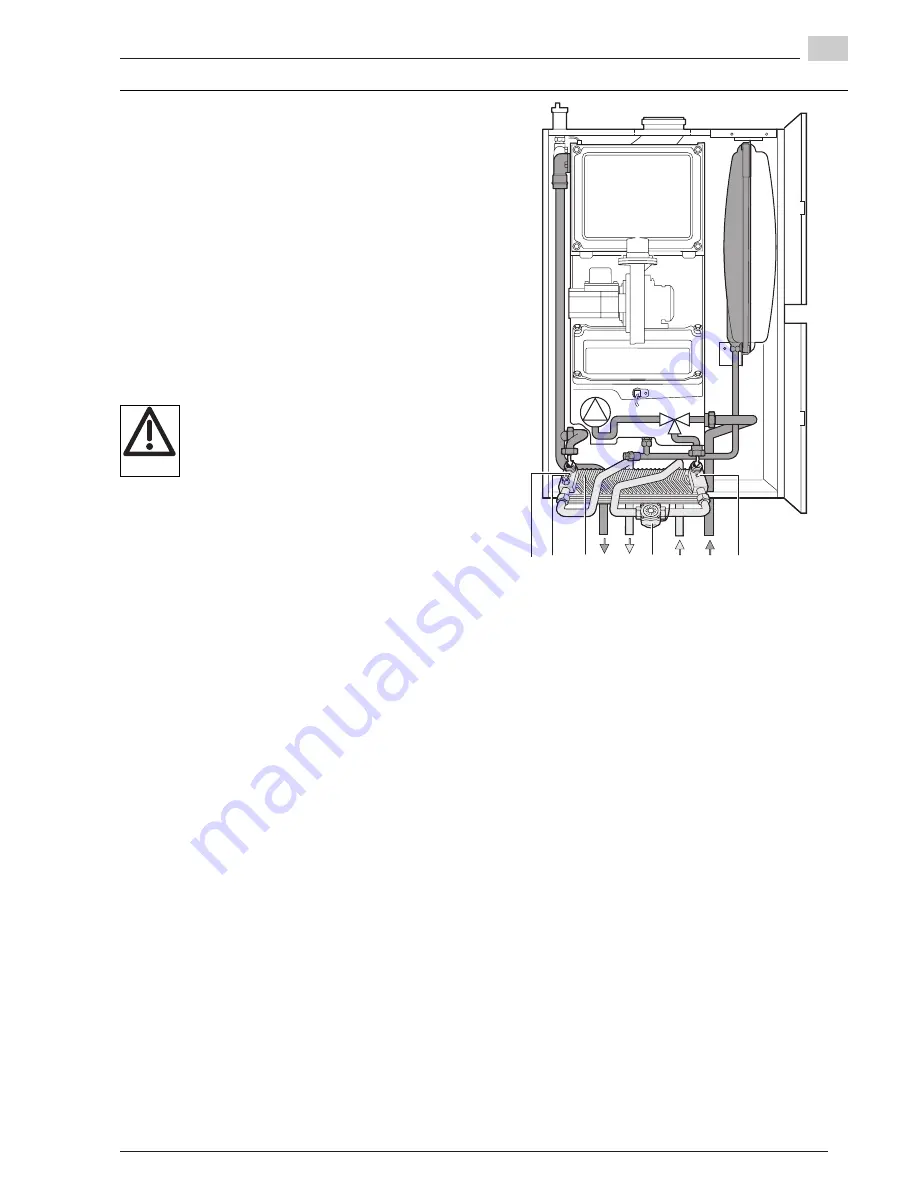

Hard domestic water can lead to scaling of

version -C .

If the water hardness is above 21° dH, a

water softener should be used in conjunction

with version C.

Version -C contains the same 3 way valve as version -W.

The drawn water quantity is determined exactly by a

throughput sensor (6) and evaluated by the Weishaupt

Condens Managers (WCM).

To ensure a constant DHW outlet temperature, version -C

is fitted with a temperature sensor (5) in the DHW

outlet. It is possible to maintain the DHW temperature so

that warm water is available immediately the tap is opened.

This function can be switched off.

Version -C is equipped with a booster function to ensure

total DHW comfort, which increases the burner rating to

approx. 28 kW with a drawn quantity of over 4

l

/

min

and an

outlet temperature > 50°C . This function can be switched

off in the heating engineer level (parameter P62).

The plate heat exchanger (8) can be removed forwards by

undoing the two flange screws (7).

3.3.5 Version -C (WTC 25-A only)

1

8

5

3

4

2

6

7

7

1 Heating

flow

2 Heating return

3 DHW

outlet

4 Cold water inlet

5 DHW sensor

6 Throughput sensor

7 Fixing screws plate heat exchanger

8 Plate heat exchanger

ATTENTION

Summary of Contents for thermo condens WTC 15-A

Page 92: ...92 Notes A ...

Page 93: ...93 A ...