6 Commissioning and startup

6.3 Setting the air pressure switch

Switching point must be checked and, if necessary, adjusted during commissioning.

u

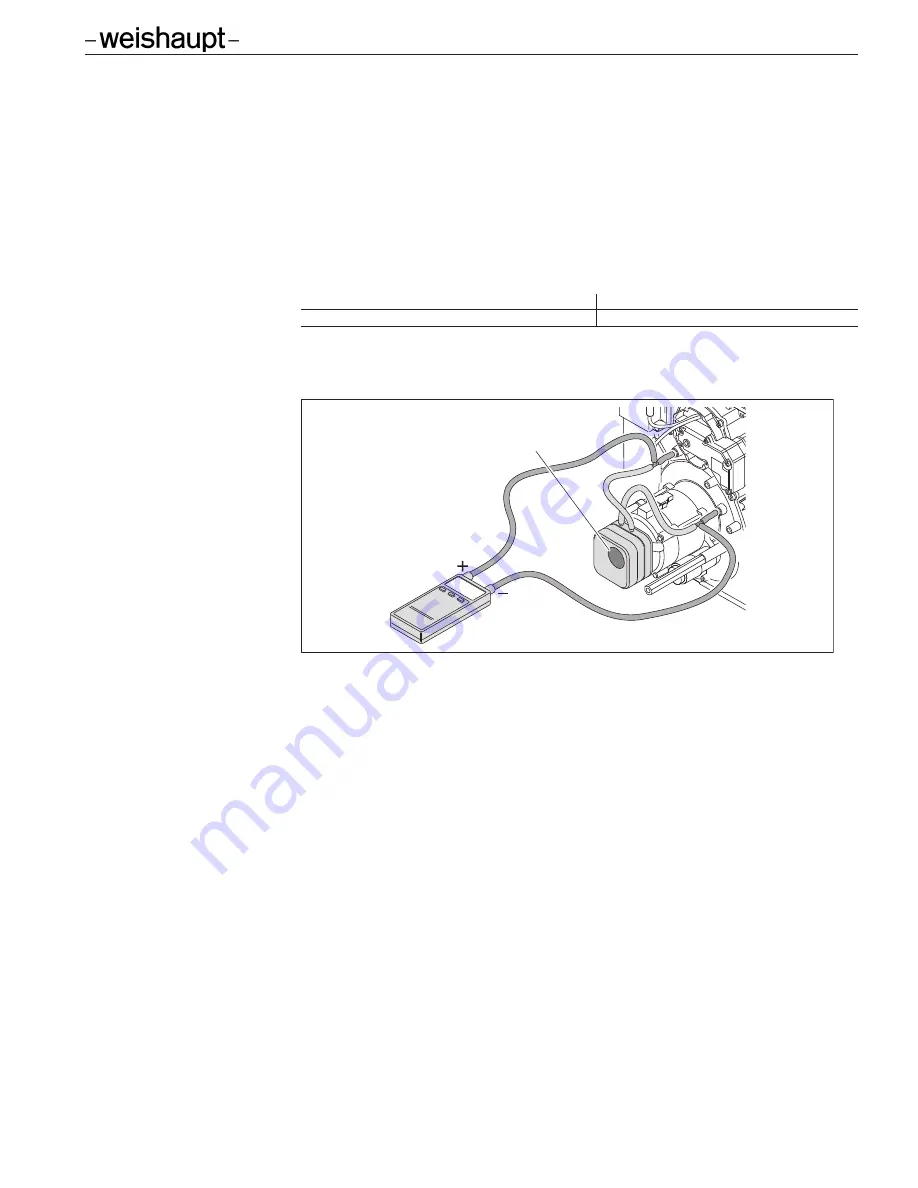

Connect the pressure gauge for differential pressure measurement.

u

Start the burner.

u

Check differential pressure over the whole operating range and determine the lowest

differential pressure.

u

Drive the burner to the point with the lowest differential pressure and turn the setting

disk on air pressure switch slowly to the right until the burner shuts down.

u

Set the air pressure switch at 80% of the verified value at the setting cam

1

.

Example

Lowest differential pressure

1.7” w.c.

Switching point air pressure switch (80%)

1.7” w.c. x 0.8 = 1.4” w.c.

Site specific conditions (such as: flue gas system, heat exchanger, boiler room, etc)

might affect the air pressure switch and, therefore, it might require a different value than

the above recommended setting.

6.4 Concluding works

u

Check the functions of all safety devices (Gas pressure switches, Thermostat,

Pressure sensor, etc.).

u

Close / remove gas pressure gauges and close all measuring ports.

u

Record burner settings and combustion test results.

u

Inform the owner on how to operate the system.

u

Keep a copy of this manual on site for the plant operator.

83055116 • 1/2016-05

42

Installation and Operating Instructions

Gas burner WG20.../1-C ZM-LN (W-FM 25)

1