Assembly and installation instructions

Circulation station WHI circuload 9 #1; Circulation station WHI circuload 9 #2

83288702

▪

1/2014-02

▪

Ext. PAW

22-24

9.2

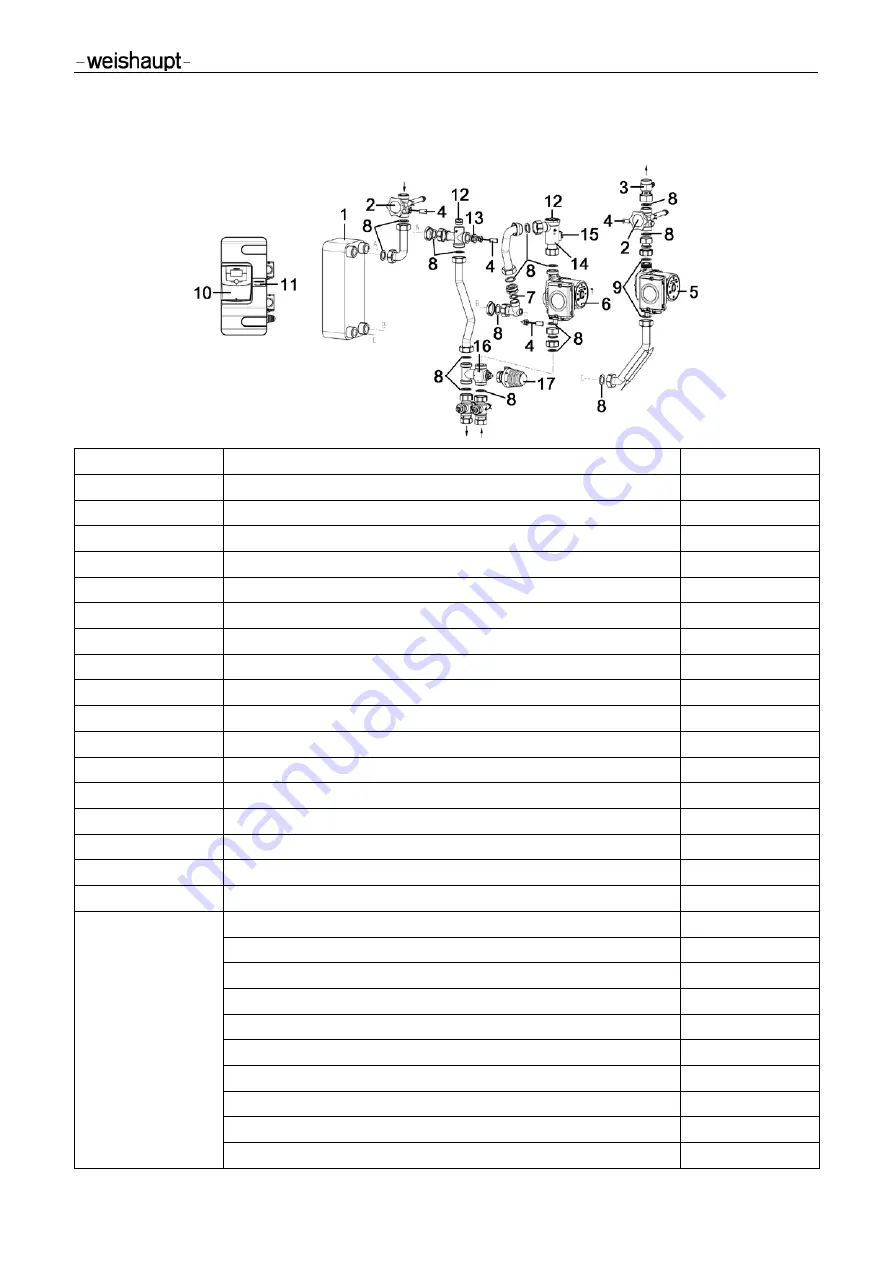

Spare parts list WHI circuload 9 #2 (40900015162)

Position number

Spare part

-w-Part number

1

Plate heat exchanger Swep IC10T/30

40900015387

2

Piston valve DN 20 G1A with drain

40900015092

3

Non return valve DN 20 G1Fl.xG1A

40900015227

4

Temperature sensor NTC 5K G¼A

40900015027

5

Circulation pump UPM2 15-75 CIL

601856

6

Circulation pump UPM2 15-75 LowFlow

601852

7

Seal 17 x 24 x 2 (¾") AFM34

48002002857

8

Seal 21 x 30 x 2 (1") AFM34

48002002847

9

Seal 21 x 30 x 2 (1") EPDM 90

40900015167

10

Solar controller WRSol 2.1 V2.0

660327

11

Name plate WHI circuload 9 #2

40900015417

12

Bleed plug G½A

40900015277

13

Reducing piece G½A x G¼I

40900015267

14

FlowRotor DN 25 90 degrees, impulse meter 2-50 l/min

40900015572

15

Hall sensor with LED connection cable

48002002867

16

Three way valve DN 20 Kvs 5.0 G1A / PN16

40900015367

17

Thermostatic head for three way valve 40-70 °C, white, M30x1.5

40900015377

Not shown in drawing

Seal 36 x 49 x 2 (1¾") AFM34

40900015397

Thermo handle -weishaupt-

48002003132

Closing plug with O ring G¼A

40900015107

Temperature sensor NTC 5K ZTF 222.2

660228

Plug fuse connection cable PWM

48002002627

Connection cable 2500 mm for Hall sensor

48002003127

Connection cable PWM 2500 mm long

48002002617

Pump cable 3 x 0.75 2500 mm long

48002002607

Plug cable temperature sensor 2500 mm

40900015037

Outlet valve with O ring G¼A

40900015097

Summary of Contents for WHI circuload 9 1

Page 2: ......