Installation and operating instruction

Oil burner WL40/1-A Z-1LN-A

9 Servicing

83319702 1/2020-10 La

73-116

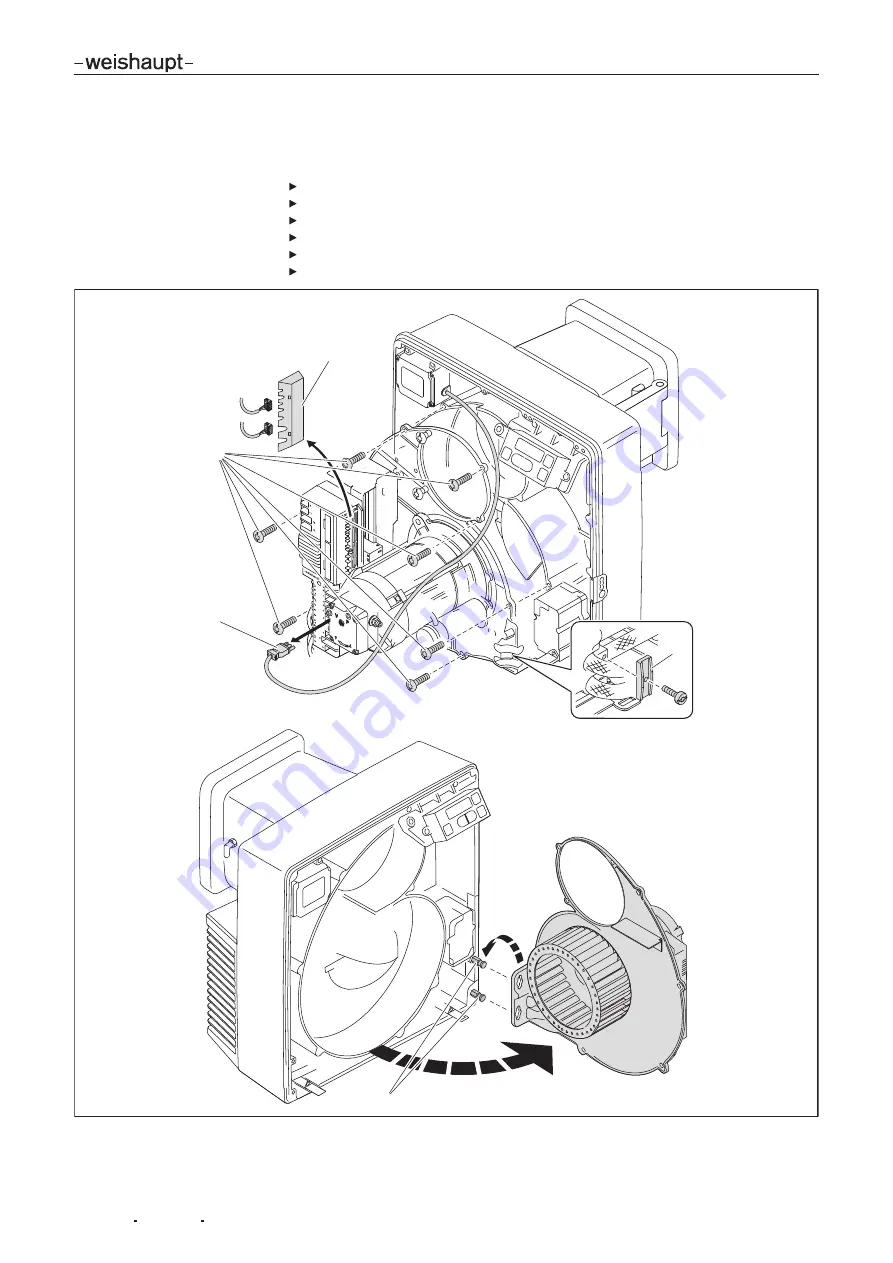

9.9 Service position

Observe notes on servicing [ch. 9.1].

Remove mixing head [ch. 9.7].

Unplug plug

4

from ignition unit.

Remove cover

2

and remove plugs.

Remove support

3

for oil hoses.

Hold housing cover and remove screws

1

.

Place housing cover onto hanging bolts

5

.

1

2

3

4

5