18-

7

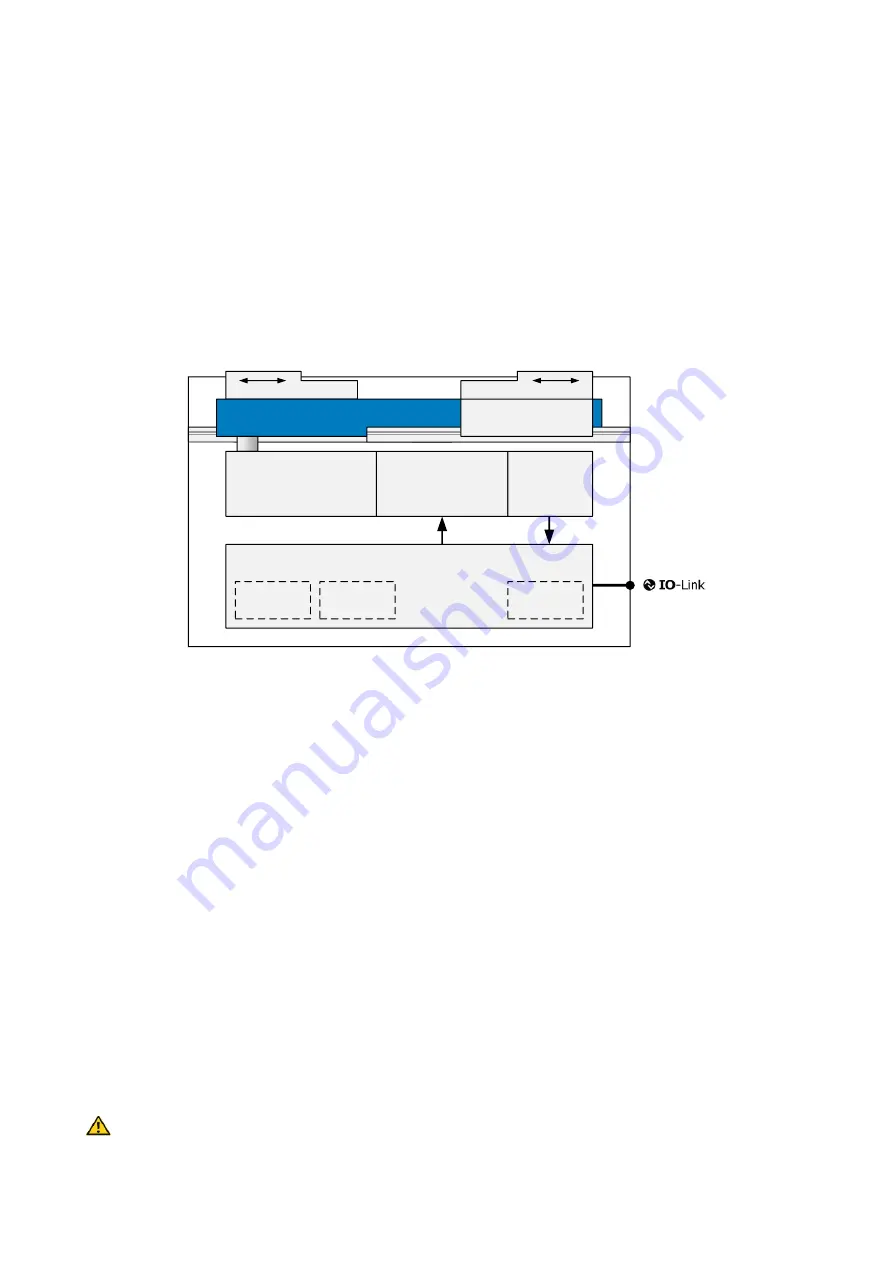

Working Principle of the Gripping Module

The gripping modules of the CLG series are servo-electrical two-finger parallel grippers with integrated grip-

ping control, a high-performance brushless drive and a high-resolution position measuring system. Move-

ment and synchronisation of the base jaws, which are guided by roller bearings, are effected via pinion-rack

kinematics. The pre-positioning capability of the gripper fingers as well as the innovative gripping force con-

trol allow the use in a variety of different handling applications in modern automation. Power supply and

connection to the process control system are provided directly via the integrated IO-Link interface. Figure

8shows the functional structure of the CLG gripping modules.

Drive

Gear Box

Grip Control

Workpiece

Detection

Diagnosis

Force

Control

Position

Detection

Figure 8: Functional diagram of the CLG gripping module

The integrated gripping control features highly optimized workpiece detection. Up to two different parame-

ter sets can be configured via IO-Link to reliably grip multiple workpieces. A position window is defined for

each workpiece, in which the gripper must adjust itself. If the CLG grips within this range, it changes from the

state RELEASED to HOLDING, which signals a successful grip to the process control.

The CLG continuously monitors the function-relevant components such as position sensors and drive and

provides detailed diagnostic information via IO-Link during operation. This helps to detect faults.

The gripping module is realized in a torsion-resistant housing made of high-strength aluminum. It has rolling

bearing guided base jaws with ground finger flange.

7.1

Typical Application

Figure 9shows a typical control-side setup with gripping modules of the CLG series, as controlled via PLC or

robot control and decentralized IO-Link master coupler (for example, a GRIPLINK ET-4 by Weiss Robotics). If

you need assistance in selecting the IO-Link components, please contact our technical support.

Damage to the IO-Link master possible. Make sure that the IO-Link master can permanently provide

the required operating current of the gripping module.