17

3.2

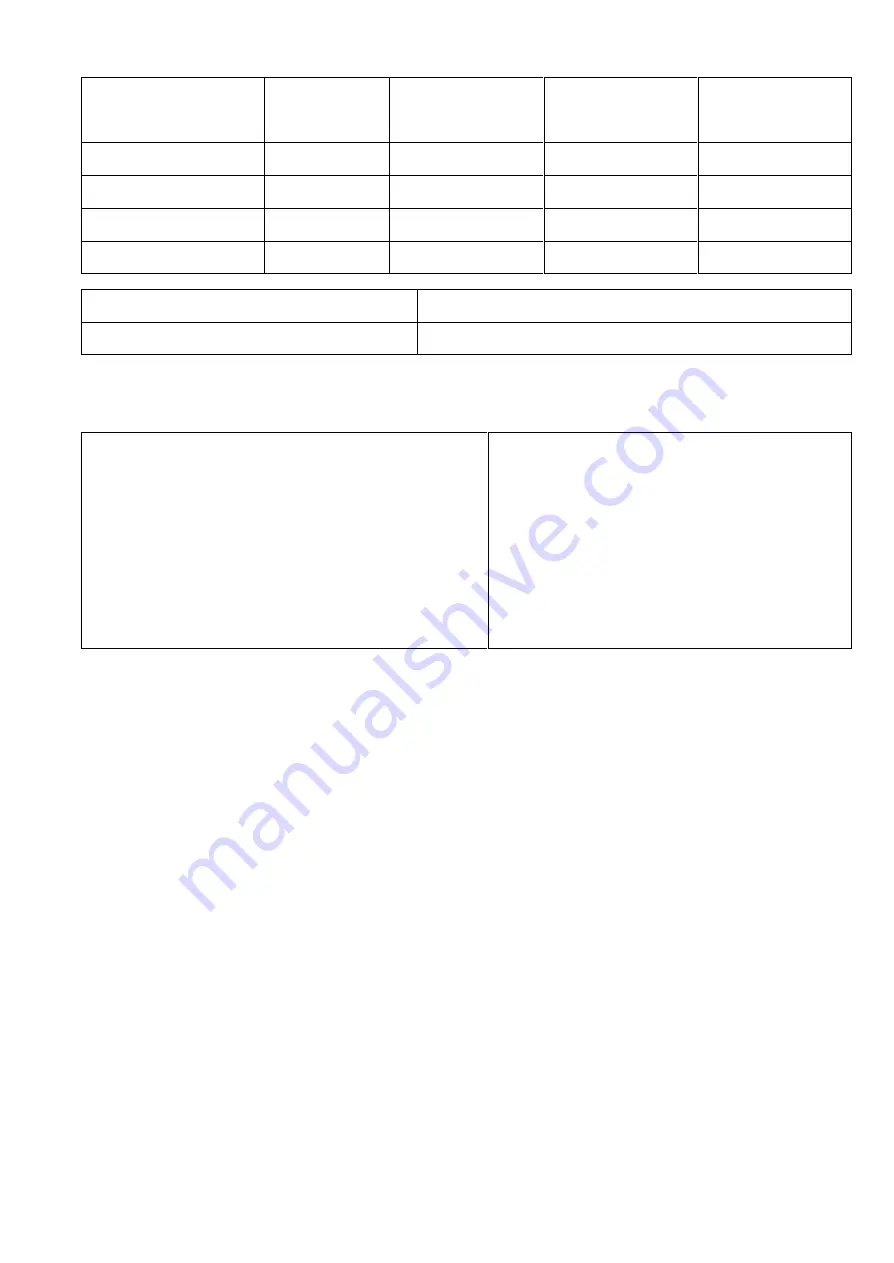

Cutting Equipment

Bar

Chain

max. cutting

depth

Drive sprocket

Chain speed at

maximum motor

speed

30 cm / 12"

320 mm

24 m/s

35 cm / 14"

3/8"

370 mm

3/8"

21 m/s

40 cm / 16"

3/8"

420 mm

3/8"

21 m/s

Height of long hole bar

14 mm

Allowable thickness bar

4,7 - 5,0 mm

3.3

Design

1

Switch handle

2 Drive

unit

3 Adjustable

clip

4 Chain

housing

5

Eccentric lever chain housing

6

W all claw

7

Cutting equipment (accessory)

8

Chain tensioning screw

9 Splash

protection

11

Eccentric lever Half-joint

12 Plug

nipple

13

Ball valve machine

14

Cover chain housing

15 Knurled

nut

16

Locking ring

17

W asher

18

Drive wheel

19

Output spindle

20

Parallel key

21

Adjustment pin

22

Main switch

23

Plug nipple FU6U

24

Power plug

25

Ball valve FU6U

26

Connection socket

27

LED

The complete sawing unit consists of the drive unit [2] with switching handle [1], adjustable handle [3] and

chain chassis [4]. The TK40 is provided electrically via the frequency converter FU6U. TK40 and FU6U

are water proof, i.e. on intended use no water can enter the motor.

3.4

Scope of delivery

Diamond chain saw with blade guard, ball valve and plug nipple, frequency converter FU6U, adapter

cable (CEE-socket/shock-proof plug) and operators manual.

3.5

Noise emissions and vibration

(EN 62841)

The typical A-weighted sound pressure level is 98 dB(A).

The typical A-weighted sound capacity level is 108 dB(A).

Uncertainty K =3 dB.

h

Vibration total values a (triax vector sum) and uncertainty K determined according to EN 62841:

h

a <2,5 m/s , K=1,5 m/s .

2

2

4.

P R E P A R A T I O N

Be convinced that the machine has not been damaged in transit. Check that the nominal voltage is

the

same as the voltage indicated on the rating plate.

4.1

Electrical connection

4.1.1

230 ~

Connect the TK40 via the frequency converter FU6U and via the adapter cable only on a properly

earthed shockproof socket. If required use only high quality extension cords with sufficient cross

section.

3/8"

3/8"