20

e)

Avoid blocking of the saw blade by too high contact pressure. Avoid too deep

cuts

. Overstressing of the saw blade increases wear and the liability for blocking and

therefore the possibility of a kickback or break of the abrasive body.

f)

If the saw blade is blocked or if you stop work shut off the machine and keep it

still until the saw blade has stopped completely. Never try to remove the

rotating disc blade out of the cut as long as the saw blade is still moving,

otherwise this may cause a kickback.

Detect and eliminate the reasons for blocking.

g)

Do not switch on the disc saw as long as it is located in the workpiece. Only

begin to move the saw blade in the cut when the saw blade has reached full

speed.

Otherwise the saw blade can be blocked, rebounds from the workpiece or

causes a kickback.

h)

Support slabs or big workpieces in order to reduce the risc of a kickback as a

result of a jammed saw blade. Big work pieces can bend under their own weight.

The work piece has to be supported at both sides of the saw blade both near the cut

and at the edge.

i)

Be very careful with “bag cuts” in existing walls or other non-visible areas.

The

saw blade can cause a kickback when hitting a gas or water pipe, electric line or

another objects.

3.

T E C H N I C A L D E S C R I P T I O N

Your TS40 is a full electrical disc saw which is only to be used for cutting masonry, asphalt, stone

and concrete in industrial usage by trained personnel.

W ater is absolutely required for cooling the motor.

The diamond saw blade consists of a prestressed metal disk which is at its circuit fixed with

segments made of a sintered mixture of diamond grains and metal powder.

The sawing process is introduced by dipping the saw blade into the material, which is to be cut. Move

the blade slowly forwards and backwards ober the work piece in order to execute the cut.

The machine may not be used for a different purpose or with a different tool.

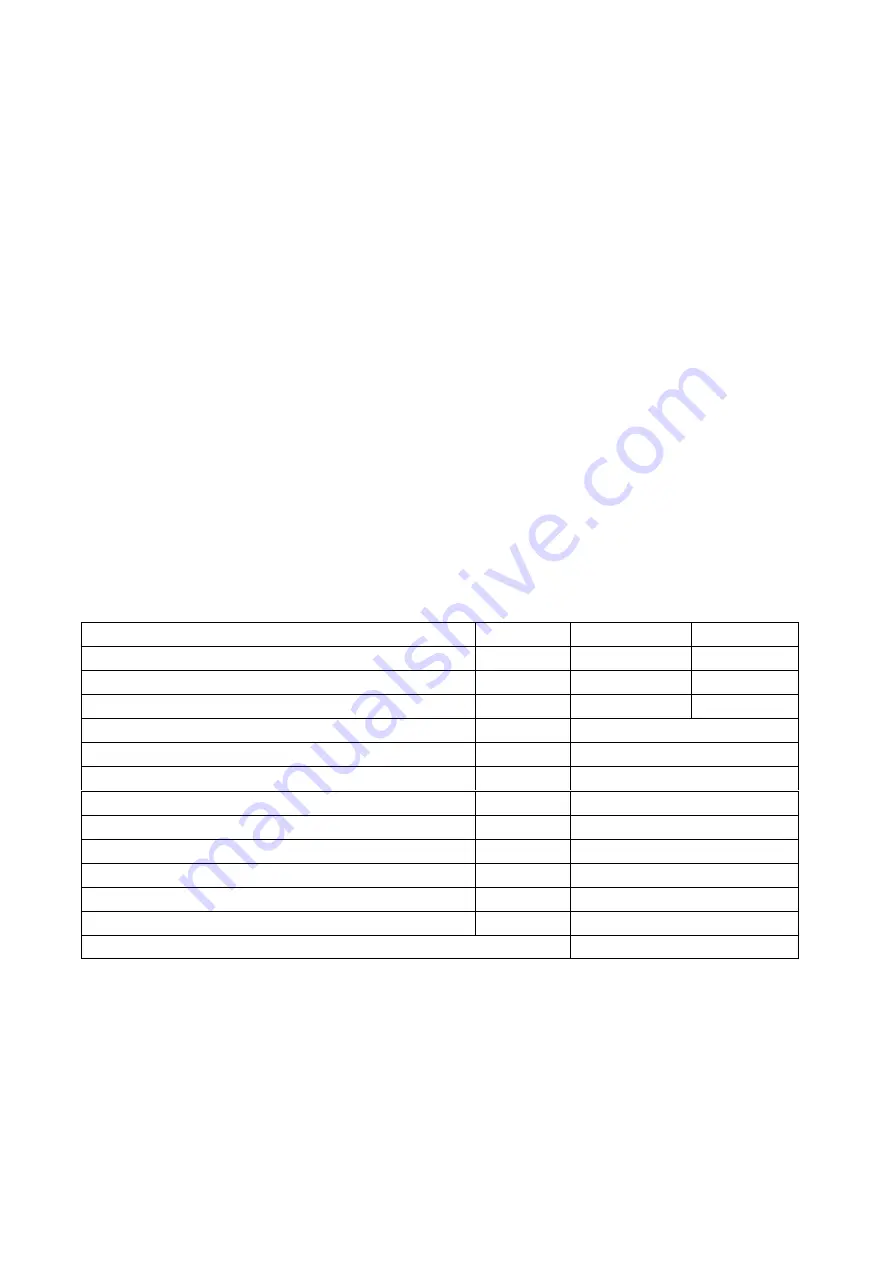

3.1

Specifications

Rated Voltage

V

230

400

Rated Current

A

16

13,5

Power Input

W

3700

6500

Power Output

W

2700

4800

Frequency - Input

Hz

50 - 60

Frequency - Output

Hz

930

Speed (full load)

1/min

2500

max. Cutting depth

mm

165

W eight - Motor

kg

9,4

Tool Fixture - Hole

mm

25,4

max. Saw Blade Diameter

mm

400

Strength of the saw blade core

mm

1,5 - 2,5

Cooling water requirement at full load

l/min

1

W ater protection class

IP 55

3.2

Design

The complete sawing unit consists of the drive unit [1] with switching handle [2], adjustable handle [3]

and adjustable blade guard [4]. A bypass valve [12] which is arrange at the gear is changed when

sawing dry for changing the water flow away from the diamond saw blade. The TS40 is provided

electrically via the frequency converter FU6 D/C. TS40 and FU6 D/C are water proof, i.e. on intended

use no water can enter the motor.

Summary of Contents for TS40 Anna

Page 3: ......

Page 4: ......

Page 16: ...12...

Page 45: ...41...

Page 59: ...55...

Page 73: ...69...

Page 100: ...96...

Page 127: ...123...

Page 157: ...153...

Page 161: ...157 RU TS40 WEKA 1 1 a b c 2 a b c d e...

Page 162: ...158 f 3 a b c d e f g 4 a b c d...

Page 163: ...159 e f g 5 a 2 1 TS40 BGV A3 6 2...

Page 164: ...160 3 4...

Page 165: ...161 3 TS40 3 1 V 230 400 A 16 13 W 3700 6500 W 2700 4800...

Page 168: ...164 4 3 FU6 D C 23 4 2 3 GARDENA WEKA 1 4 4 12 13 8 4 5 400 25 4 1 1 5 2 5 4 6 8 6 9 10...

Page 169: ...165 SW17 11 4 7 3 7 4 8 5 5 www weka elektrowerkzeuge de...

Page 171: ...167 15A 10A D E B U G BSZ gesamt BSZ heute BSZ Kunde STZ 1 4 4 2 Apple 2 500...

Page 173: ...169 invalid firmware...

Page 176: ...172 2002 96 EG 0520...