OPERATION

WARRANTY

SIX-SIDED SPANNER STORAGE

When the six-sided spanner isn't in use, it can be stored

conveniently in the base of the tool

OPERATION

It is recommended that you first mark your intended

cutting line with a pencil or appropriate marker. Start the

tool and wait a short moment until the blade achieves

maximum speed Put the bottom base on the work piece

and move forward slowly along the cutting line.

Take extra care when cutting curved lines. This reduces

the stress on the blade and avoids breakage.

CUTTING ANGLES

Use the six-sided spanner to adjust the base plate and set

the required angle Loosen the bolts and slide the base

backwards away from the blade. Use the angle markings

on the base plate to accurately set the angle then slide the

base plate back to position and re-tighten the bolts.

While the tool is made to precise settings we recommend

that for cutting requiring extreme accuracy. a checking

device such as a protractor is used. Adjustment of the base

plate is critical for precision cutting. The base plate can be

tilted from 0 to 45° left or right.

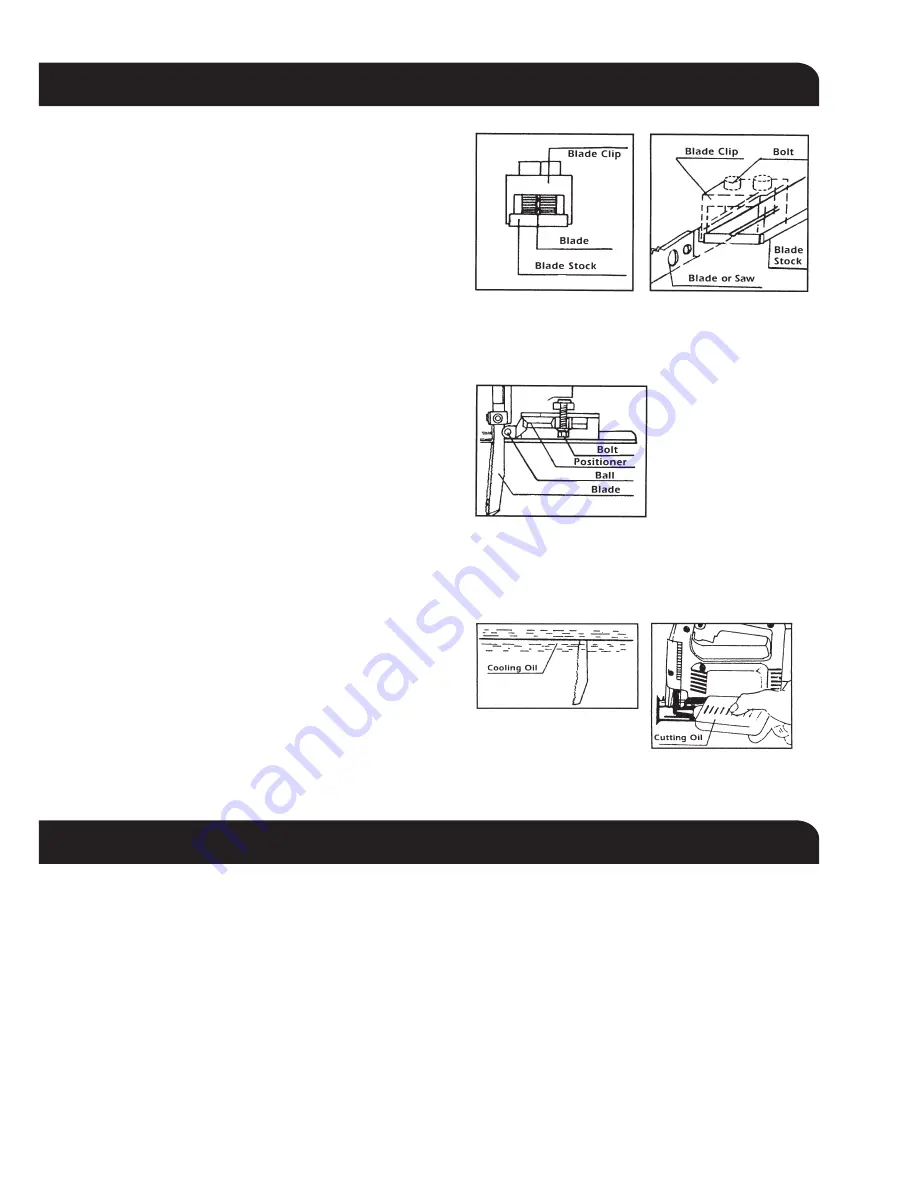

JIGSAW BLADE MOUNTING

Remove the power plug from the socket before

changing blade.

Various kinds of Jigsaw blades fit into the stock of the

tool. Please check with your retailer to ensure proper fit

before purchasing new blades. Use the six-sided

spanner to loosen or tighten the stock and mount the

blade according to the following diagrams.

USE OF THE BALL (or ROLLER GUIDE)

Loosen the bolts which fix the base plate and positioner

with the six sided spanner. Slide the positioner so that

the ball touches the blade then

tighten the bolt.

CUTTING METAL

When cutting metal you must use a suitable cooling

agent like cutting oil. Unnecessary wear and stress is

placed on the blade without the use of cooling

assistance.

THIS WARRANTY FORM SHOULD BE RETAINED BY

THE CUSTOMER AT ALL TIMES

PURCHASED FROM:_______________________________

DATE PURCHASED: _______________________________

The warranty is only made available by returning the tool

to the place of purchase with a confirmed register receipt.

6-MONTH REPLACEMENT WARRANTY

Your Wel-Bilt tool is covered by a 6-month replacement

warranty from the date of purchase. Industrial or high

frequency use will void this warranty. The warranty

covers faulty parts or workmanship.

WARNING

The following actions will result in the warranty being void.

• If the tool has been operated on a supply voltage

other than that specified on the unit.

• If the tool shows signs of damage or defects caused

by or resulting from abuse accidents or alterations.

• If the tool has been disassembled or tampered with in

any way.

Warranty excludes consumable parts such as brushes,

batteries, sanding pads, blades, discs and drill bits.