WARNING! BE SURE TO DISCONNECT THE

ANGLE GRINDER FROM THE POWER SUPPLY

BEFORE ATTACHING OR REMOVING THE DISC OR

ATTACHMENT.

WARNING! MAKE SURE THAT A GRINDING

OR CUTTING DISC IS MOUNTED WITH THE LABEL

ON TOP OR FACING THE ANGLE GRINDER.

IF YOU ARE FITTING ANY OTHER KIND OF

ATTACHMENT, REFER TO ATTACHMENT FITMENT

INSTRUCTIONS. Northern Tool + Equipment WILL

NOT BE RESPONSIBLE FOR ANY DAMAGE OR

INJURY CAUSED DUE TO THE INCORRECT FITMENT

OF GRINDING OR CUTTING DISCS OR ANY OTHER

KIND OF ATTACHMENT. INCORRECT ATTACHMENTS

CAN CAUSE THE MOTOR TO BURN OUT,

GENERALLY DAMAGE THE TOOL OR CAUSE INJURY.

Attaching and removing the grinding disc provided:

• Inspect the disc before fitting and during use to ensure

it is not deformed or cracked.

• Ensure that the guard is fitted and at an angle which

ensures it is between you and the grinding disc. The

guard is there to protect you from dislodging objects

at the work piece and from accidental contact with the

disc, of your hand, fingers or other parts of yourself.

• Do not fit or use a grinding disc for cutting

applications – For cutting, use a cutting disc and ask

your hardware retailer for advice regarding the type of

material you wish to cut. Grinding discs are used for

grinding metal only.

• The grinding disc provided is not solid. It is made from

grit which is bonded together with reinforcement and

adhesives. It is always possible that a part of the disc

can dislodge and fly away from the tool at high

speed. This is why you must wear the appropriate

safety equipment (glasses, gloves and protective

clothing) described herein and follow all safety

instructions also described herein.

• Do not use any kind of attachment (discs or otherwise)

that has a diameter of greater than 4in. (100mm).

• Remove the outside retaining flange by hand if loose.

If tight, depress the spindle lock button at the top of

the gear box housing, rotate the spindle to locate the

lock position. Once the spindle is locked and cannot

be rotated, use the wrench supplied to loosen the

retaining flange.

• Remove the grinding disc from its envelope.

• Holding the angle grinder with the spindle facing

upwards, ensure the non threaded flange is on the

spindle and located correctly. The two machined flat

sections on one side of the non threaded flange must

face the angle grinder and locate in the appropriate

position on the spindle.

• Insert the grinding disc onto the angle grinder spindle

with the disc label facing the angle grinder. The hole

in the disc should be located onto the spindle. Ensure

that the hole in the disc locates and fits firmly into the

ring section of the non threaded flange.

• Screw the threaded flange onto the spindle with the

protruding ring section facing the angle grinder. This ring

section must locate with the hole in the grinding disc.

• Tighten the threaded flange by locking the spindle and

tighten with the spanner provided.

• Removal of the disc is conducted in reverse order

to the above.

• Regularly check that the disc retaining flange has

not loosened during use.

Note:

• When fitting a cutting disc, the ring section on outer

flanges should face away from the disc.

• When fitting the wire wheel, the ring section on

the outer flange should face into the wheel.

Fitting of Sanding Accessory:

• Thread backing wheel onto grinder first.

• Select the grit of paper that you wish to use.

• Place grit on wheel and then thread the paper

retaining nut on and tighten using spanner and

spindle lock.

ASSEMBLY AND INSTRUCTIONS

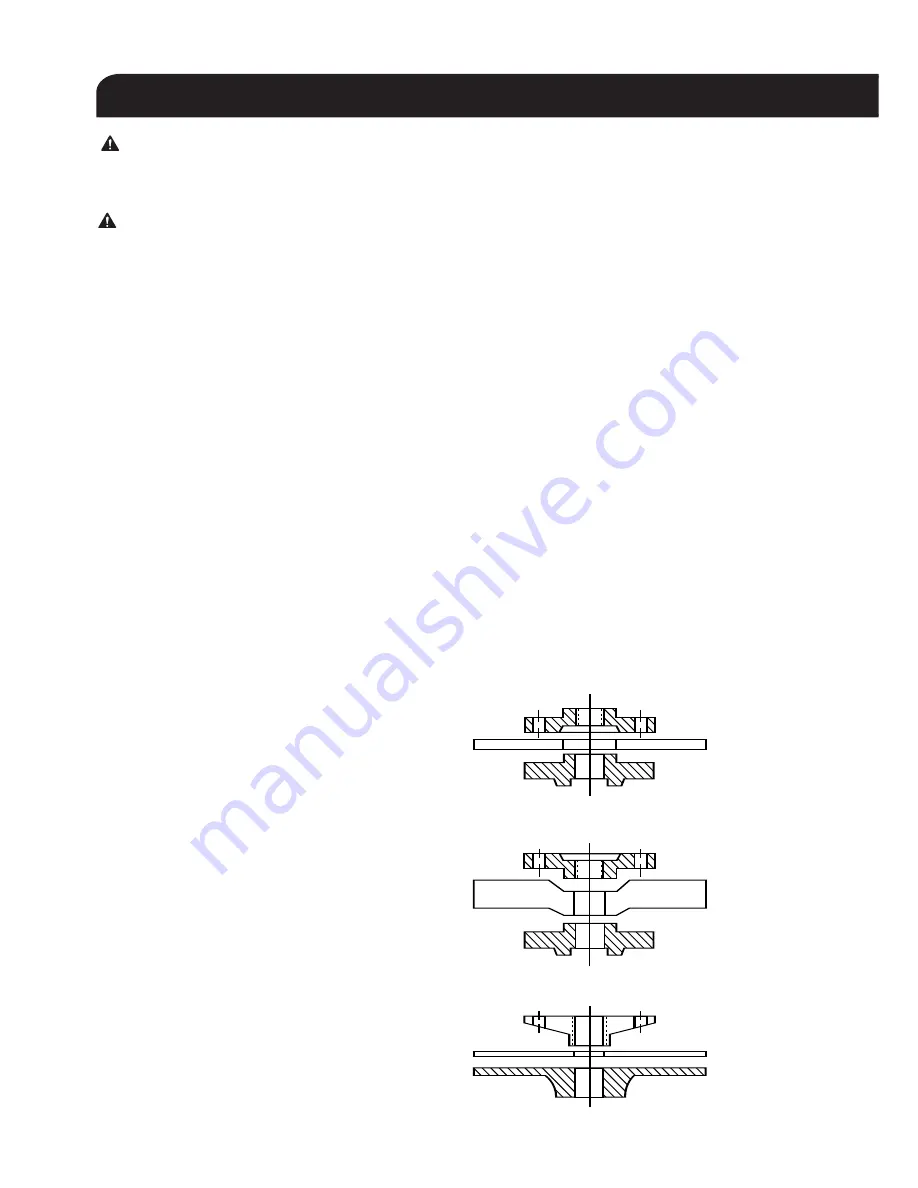

For use with cutting disc

Outer Flange

Inner Flange

For use with grinding disc and wire wheel

Outer Flange

Inner Flange

For use with sandpaper

Outer Flange

Inner Flange