5.

ELECTRICAL

Install in accordance with local codes and/or

the National Electric Code ANSI/NFPA No.

70-1990 (USA) or the Canadian Electric Code

CSA Standard C22.1 (Canada). A separate

fused disconnect switch must be supplied and installed. The

kettle must be electrically grounded by the installer.

The electrical supply must match the power requirements

specified on the kettle's rating plate. The copper wiring must

be adequate to carry the required current at the rated

voltage.

Note: Maximum voltage for LVD (low voltage directive for

Europe) to be 440 volts for CE marked appliances.

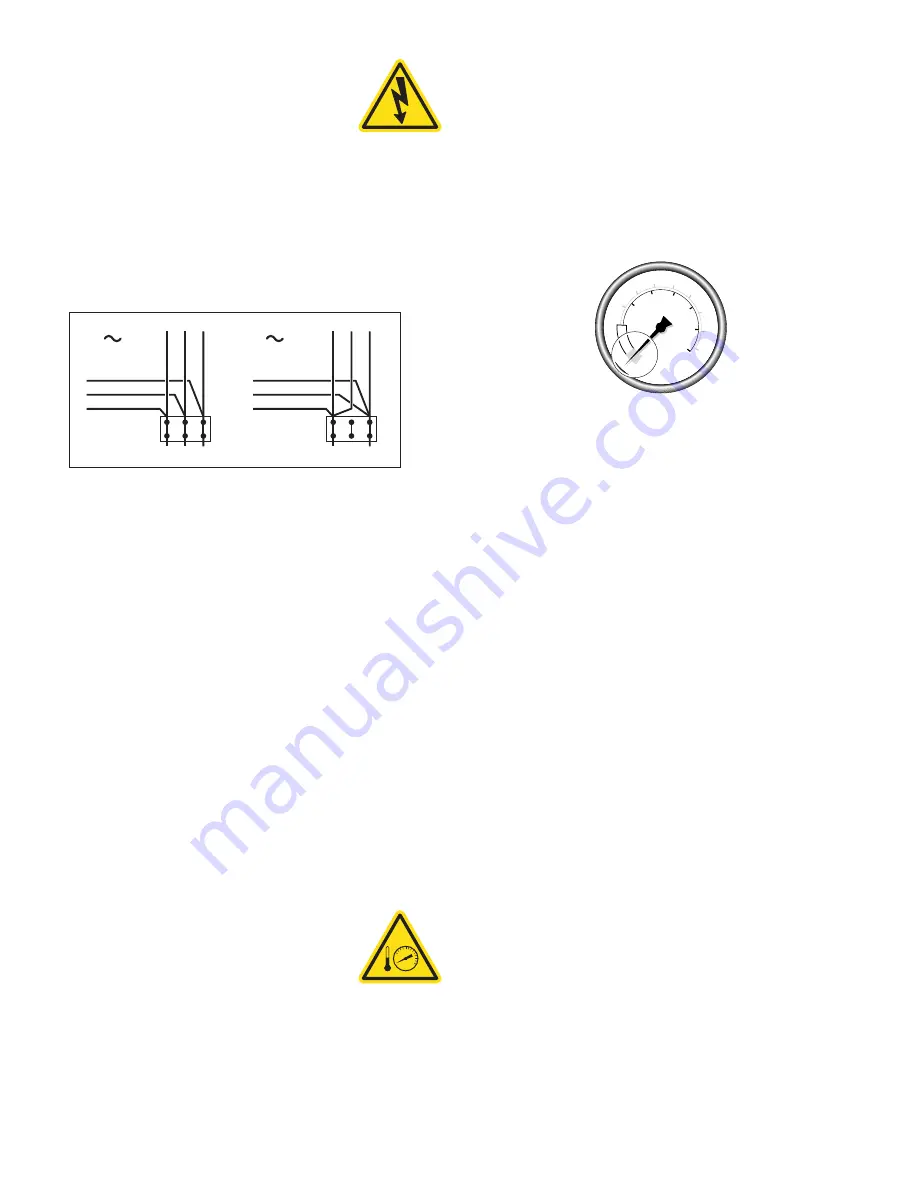

The kettle is wired for 3-phase operation at the factory. For

single phase operation, rewire the terminal block to that

shown in the above diagram.

Note: Ensure main power is turned off before connecting

wires.

Stationary Models

Remove the screws securing the dome-shaped service cover

underneath the kettle and remove the cover. A wiring diagram

is affixed to the inside of cover. Fasten permanent copper

wiring to the three-connection terminal block, Be sure to

connect ground wire to the separate ground terminal

connector (ground lug). Slide the cover's slot over the wiring

and secure the cover to kettle with the screws.

Tilting Models

First remove the handwheel by loosening the allen screw.

Then remove the two screws at the front and rear of the

console cover and remove the cover. A wiring diagram is

affixed to the underside of the console cover. Feed

permanent copper wiring through the cut-out in the bottom of

the console, and fasten to the three-connection terminal

block. Be sure to connect the ground terminal connector

(ground lug). Replace the console cover and handwheel.

INSTALLATION CHECKS

Although the kettle has been thoroughly

tested before leaving the factory, the

installer is responsible for ensuring the

proper operation of kettle once installed.

Visual Checks

1. Check Tilting (tilting kettles):

A/ Gearbox tilts kettle smoothly and freely.

RED

YELLOW

BLACK

B

L

A

C

K

B

L

U

E

R

E

D

L1 L2 L3

3

RED

YELLOW

BLACK

B

L

A

C

K

B

L

U

E

R

E

D

L1

L2

1

2. Insure there are:

A/ Three lag bolts securely holding each foot

B/ The bottom cover (stationary kettles) is in place and

held with a nut.

C/ The console cover (tilting kettles) is in place and held

with a screw.

Performance Checks

1. Supply power to the kettle by placing the fused

disconnect switch to the "ON" position.

2. Before turning the kettle on, read the Vacuum/Pressure

Gauge. The gauge's needle should be in the green zone.

If the needle is in the "VENT AIR" zone, follow Kettle

Venting Procedure in the Service Manual.

3. Turn the kettle's ON/OFF Switch/Solid State Temperature

Control to "1" (Min.). The Heat Indicator Light (Green)

should remain lit, indicating the element is on, until the

set temperature is reached (130°F/54°C). Then the green

light will cycle on and off, indicating the element is

cycling on and off to maintain temperature.

4. Tilt the kettle forward (tilting models only). After a few

moments the Low Water Indicator Light (Red) should be

lit when the kettle is in a tilted position. This light

indicates that the element has automatically been shut off

by the kettle's safety circuit. This is a normal condition

when the kettle is in a tilted position.

5. Raise the kettle to the upright position. The Low Water

Indicator Light (Red) should go out when the kettle is

upright.

6. Turn the ON/OFF Switch/Solid State Temperature Control

to "10" (Max.) and allow the kettle to preheat. The green

light should remain on until the set temperature

(260°F/127°C) is reached. Then the green light will cycle

ON and OFF, indicating the element is cycling ON and

OFF to maintain temperature. Fill the kettle with cold

water to the steam jacket’s welded seam. Refer to the

Temperature Range Chart for the time required to bring

the water to a boil.

7. When all testing is complete, empty the kettle and turn

the ON/OFF Switch/Solid State Temperature Control to the

“OFF” position.

CLEANING

After installation the kettle must be thoroughly cleaned

and sanitized prior to cooking.

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

EN

T

A

IR

0

Summary of Contents for Cleveland KEL-100

Page 19: ...18 WIRING DIAGRAM 200 240v...

Page 20: ...19 WIRING DIAGRAM 480 600v...

Page 26: ...25 CONTROL CONSOLE COMPONENTS HAND TILT 44 45 43...

Page 28: ...27 CONTROL CONSOLE COMPONENTS POWER TILT 41 42 40 44 45 43...

Page 31: ...30...