14

Part Number: 9294045C 03/22

Operation

Section 3

FREEZERS

Plug the unit in to begin operation. At initial start-up or

anytime power is disconnected, then reconnected to the

unit, the control will start the unit in defrost.

The unit can be turned on and off by pressing the on/off

button on control. The unit will begin in a defrost cycle if it

is turned on at the control.

After initializing, the control will immediately enter a

DEFROST mode. The compressor and condenser fan as well

as the evaporator fan will remain off until initial defrost

is complete. This initial defrost cycle may take up to 15

minutes to complete, then the freezing cycle will begin.

After initializing and the defrost cycle, the electronic

temperature control will cycle the compressor, evaporator

fan motor, and condenser fan motor to maintain box

temperature at the control setting.

With the doors closed, the temperature of the cabinet

should reach 0°F (-18°C) on freezers in about one hour

after the freezing cycle begins. The electronic temperature

control constantly monitors box temperature as well as

evaporator coil temperature to maintain consistent product

temperatures. As an added energy-saving feature, the

electronic controller will switch the evaporator fan motor

on and off with the compressor and condenser fan motor.

During normal operation the evaporator fan may cycle

and/or pulse independently of the compressor. Consult

the service manual or contact Technical Support at

1-844-724-CARE if you are unsure of the proper

function.

Electronic Temperature Control Location & Adjustment

The control is located in the control box at the rear of the

unit. It is factory set at mid-range to maintain about -3°F

(-18°C) box temperature. To adjust for colder temperatures,

press and hold the set button until the current set point

appears and is blinking on the screen. Press the down

arrow to adjust to the desired temperature. Press the set

button to save the temperature.

To adjust for warmer temperatures, press and hold the set

button until the current set point appears and is blinking

on the screen. Press the up arrow to adjust to the desired

temperature. Press the set button to save the temperature

Freezer Automatic Defrost

The control is set to defrost every 5 hours. The maximum

defrost duration is 35 minutes.

Freezer Manual Defrost

If a manual defrost is desired, simply unplug the unit for

several seconds, then plug unit back in. This will cause the

control to re-initialize and then enter a defrost cycle. The

unit can also be put into a manual defrost by pressing and

holding the snowflake button on the control.

When the control enters the defrost mode, whether manual

or automatic, it switches on the compressor and condenser

fan motor, and energizes the hot gas solenoid to warm the

evaporator coil and melt all frost accumulated during the

previous refrigeration cycle. The control will continue the

defrost cycle for a MAXIMUM of 35 minutes depending on

the amount of frost accumulated on the evaporator coil.

After the defrost cycle is complete, the control returns

to a normal refrigeration cycle, however the evaporator

fan motor will not switch on for two minutes AFTER

the compressor and condenser fan motor have begun

operating.

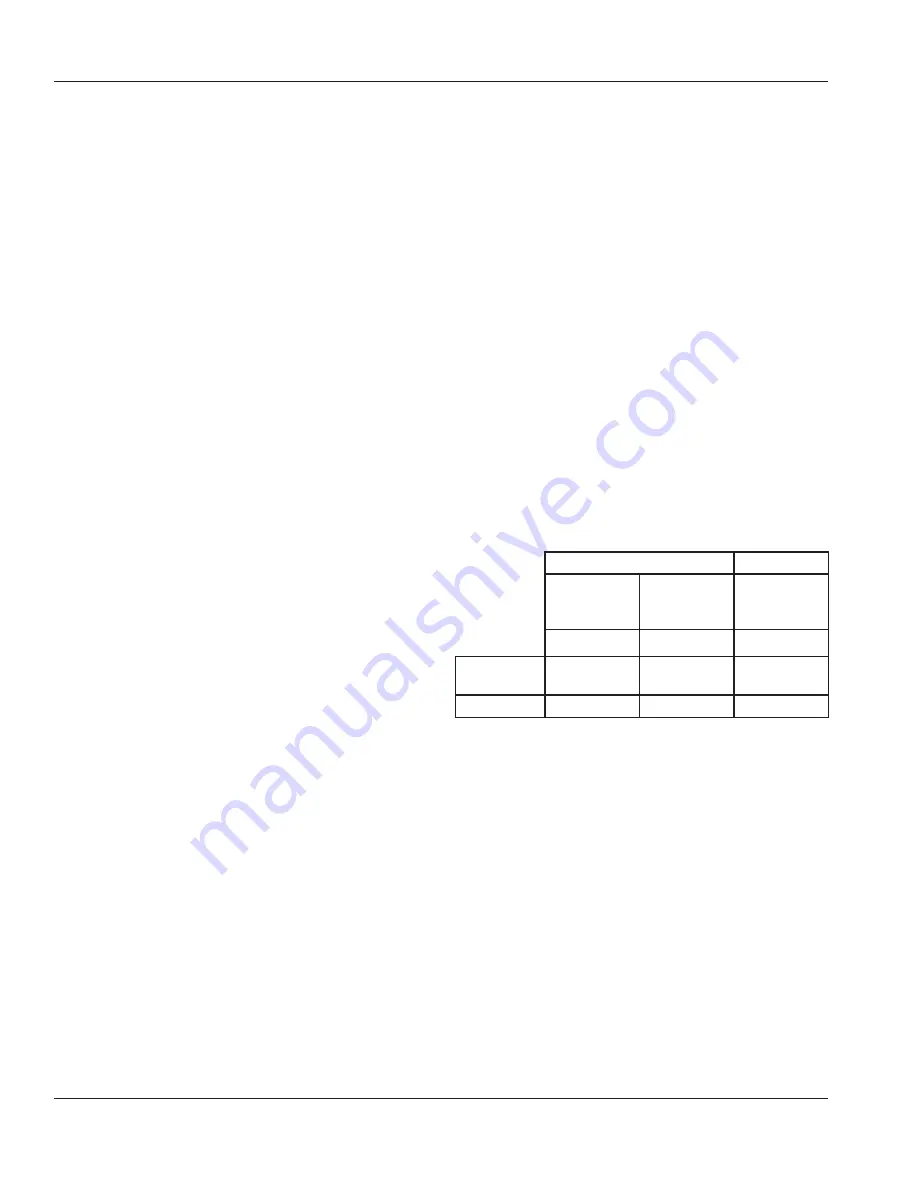

EVAPORATOR FAN OPERATION

Cooling Cycle

Defrost Cycle

Compressor

On

Compressor

Off

Compressor

Off Refrig. /

On Freezer

Evap Fan

Evap Fan

Evap Fan

R290

Refrigerators

On

On

On

R290 Freezer

On

Off

Off

Summary of Contents for Delfield 4000P Series

Page 10: ...10 Part Number 9294045C 03 22 Installation Section 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 11: ...Part Number 9294045C 03 22 11 Section 2 Installation THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 18: ...18 Part Number 9294045C 03 22 Troubleshooting Section 5 406P and 4048P Wiring Diagram ...

Page 19: ...Part Number 9294045C 03 22 19 Section 5 Troubleshooting 407P Wiring Diagram ...