8

Part Number: 9294045 07/17

Installation

Section 2

Caster Or Leg Installation

DANGER

Legs or casters must be installed and the legs or casters

must be screwed in completely to prevent bending.

When casters are installed the mass of this unit will

allow it to move uncontrolled on an inclined surface.

These units must be tethered/secured to comply with

all applicable codes.

n

Warning

The unit must be installed in a stable condition with

the front wheels locked. Locking the front casters after

installation is the owner’s and operator’s responsibility.

n

Warning

Use a jack to lift the refrigeration unit off the ground

just far enough to remove the leg/caster. Place blocking

underneath the unit. Do not work underneath a raised

unit without proper blocking. Do not lift the unit more

than necessary to remove the leg/caster. Lifting the unit

too far can make the unit unstable.

,

Caution

All single-section units require that the sw ivel casters

be mounted on the front and rigid casters be mounted

on the rear.

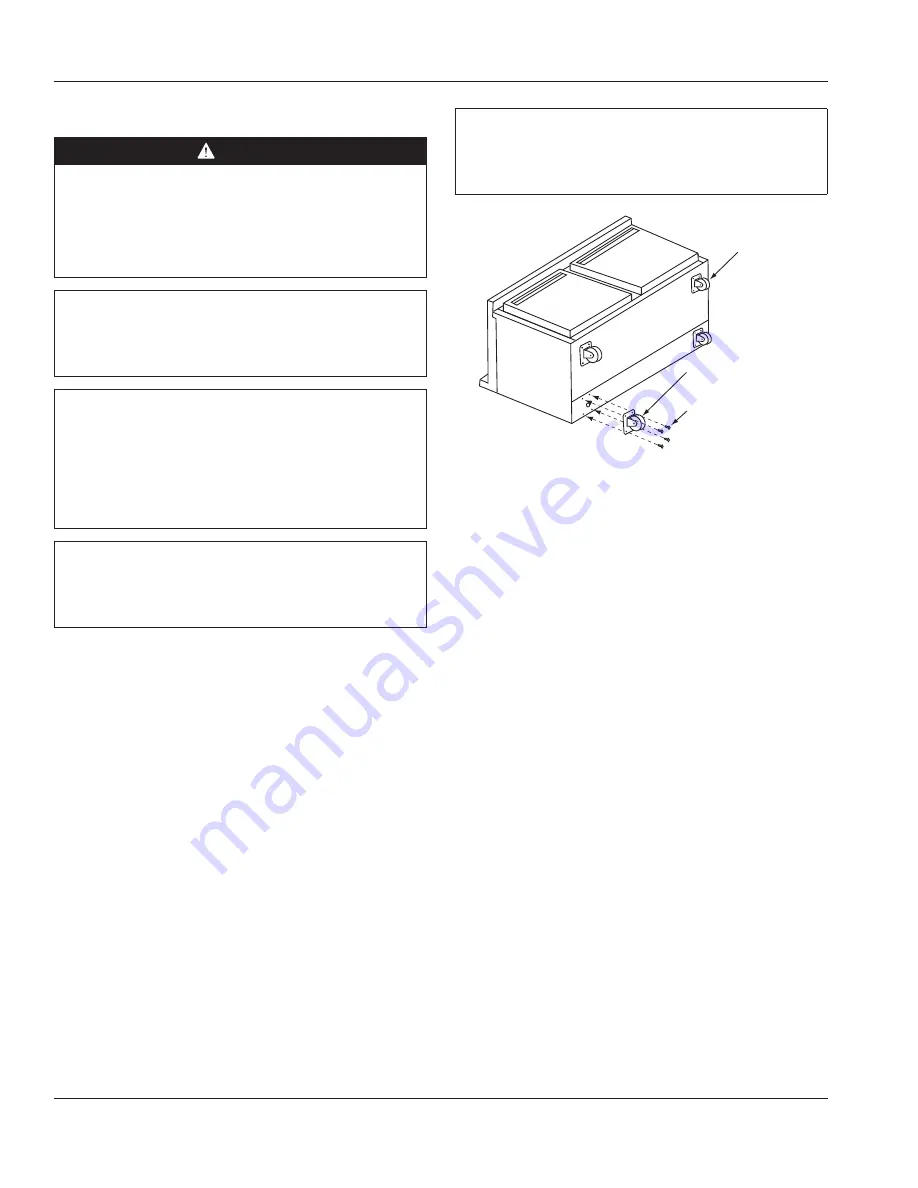

1. Carefully place the unit on its back.

2. Located at each caster mounting location are 4 Phillips

head screws, for a total of 16 screws. Remove them.

3. Place a locking plate caster or leg over one of the front

holes, matching the 4 mounting holes to the pre-drilled

holes in the underside of the unit. Insert 4 Phillips head

screws and tighten. Repeat with the other locking front

caster or leg.

4. Repeat step 3 with the non-locking casters or legs in

the rear of the unit.

5. Carefully lift the unit upright.

,

Caution

After installing casters, the unit must stand upright for

twenty-four (24) hours before being powered up to

assure oil return to the compressor sump.

Plate Casters

With Locks

Plate Casters

Without Locks

Screws

LEG LEVELING

All four legs are adjustable. Adjust each leg until the unit is

stable and level left to right. If necessary adjusting the front

legs slightly higher than the rear by about 1/8” (3mm) will

help the door remain closed.