124

REFRIGERATION DIAGNOSTIC PROCEDURE

1. Install and insulate a temperature lead on the

compressor suction line within 6” of the compressor.

2. Install and insulate a temperature lead on the

compressor discharge line within 6” of the

compressor.

3. All doors and panels must be in place during the

diagnostic procedure.

4. Refer to the “Cycle Times, 24 Hr. Ice Production and

Refrigerant Temperature Charts” on page 157 to

determine the correct operating temperature range

for your air and water temperature. Normal operating

temperatures will be within 10% of the data in the

charts.

5. Record the temperatures throughout the freeze and

harvest cycles and compare suction and discharge

temperatures to your model in the charts starting on

NOTE: First cycle is not used for refrigeration system

diagnostics. Run a minimum of two cycles to allow the

system to stabilize and start recording temperatures three

minutes after the second cycle starts.

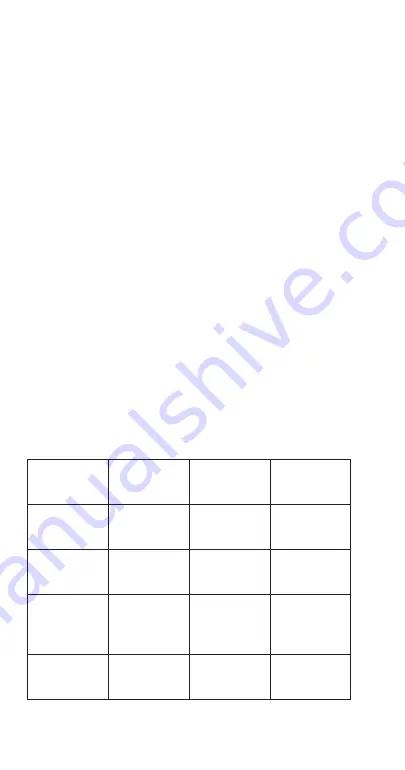

Discharge Line

Temp

Suction Line

Temp

Ice Fill Pattern

Refer to

Diagnostics

for:

Normal

Normal

Less fill on the

outlet side of

the evaporator

This is normal

operation

Low (20°F

[-7°C] or more)

Low 20°F (-7°C)

or more)

Less fill on the

outlet side of

the evaporator

Expansion

Valve Flooding

Normal or

High

High 10°F

(-12°C) or

more)

Less fill on the

outlet side and

top 2 rows of

the evaporator

Low on

Refrigerant

or Expansion

Valve Starving

Normal

Low 5°F (-15°C)

or less)

Less fill on the

outlet side of

the evaporator

Refrigerant

Overcharge

Summary of Contents for Manitowoc NEO UDP0080A

Page 2: ......

Page 18: ...18 Part Number STH098 06 19 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 74: ...74 Part Number STH098 06 19 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 166: ...166 Part Number STH098 06 19 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 176: ...176 Part Number STH098 06 19 ELECTRONIC CONTROL BOARD UDP0080 1 2 3 4 5 6 7 8 9 10...

Page 179: ......