4

Section 1: INSTALLATION

1.10 Introduction

This manual has been complied not only for the care and maintenance of the DUOSEAL pump now in your

possession but as a helpful reference and guide for many problems which are usually associated with mechanical

vacuum pumps. Take time to read these instructions carefully and preserve this manual for future reference; we

think it will be useful to you.

1.11 Unpacking

Carefully remove the pump from the shipping case and unfasten and remove the wooden skid. Preserve all

paper work and inspection tags for future reference. If damage has occurred from shipment a claim must

be fi led with the carrier immediately; preserve the shipping container for inspection by the carrier. If you are

required to communicate with your dealer or with Welch Vacuum be sure to include your order numbers for quick

identifi cation. Do not return the pump to the factory without fi rst completing the on-line request form for returned

goods authorization at www.welchvacuum.com.

1.12 Pump

Mounting

1.121 Mounted

Pumps

Rubber bumpers are supplied with most of our mounted pumps, either loosely or attached. Bumpers are

excellent for applications involving a semi-fl exible surface such as a bench top; they help to isolate noise and

eliminate creeping. For more rigid requirements, the pump base may be bolted directly to a fi rm foundation with

or without the bumpers. All DUOSEAL pumps should be mounted in a horizontal plane.

1.122 Unmounted

Pumps

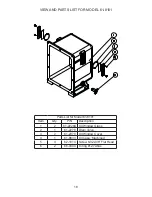

If you have purchased an unmounted pump, refer to parts list for information concerning the motor, motor pulley

and belt necessary to drive your particular pump at the recommended speed.

1.13 Pump

Location

The pump should be located preferably in a clean and well ventilated area and adequate space should

be provided wherever possible for routine maintenance such as changes of oil and belt adjustments and

replacements. Above all, the pump should be located as closely as possible to its system in order to utilize it most

effi ciently. Its location should include such determining factors as the length and size of connections, the number

of bends and the type of exhaust connections.

1.14

Exhaust Provisions (See Accessory section in back of this manual.)

Exhaust connections will be determined by the type of system to be exhausted and the desired cleanliness of

the atmosphere surrounding the pump. Under normal conditions of mild evacuation nothing more than the dust

cap will be necessary to cover the port. Where relatively high gas fl ows are involved or where the presence of oil

vapor is objectionable an exhaust fi lter may be fastened to the exhaust port in place of the dust cap. The exhaust

fi lters used on our pumps are capable of absorbing and restricting any vapor particle larger than 0.1 micron.

WARNING

Never block the Exhaust Port. If the exhaust port is blocked,

pressure will build-up in the pump with the potential of the pump

body bursting and causing possible injury to personnel in the area.

Where extreme exhaust conditions are encountered it is best to pipe the exhaust direct out of the building. Welch

recommended wire reinforced PVC, metal pipe or thick walled rubber hose be used as exhaust lines to avoid

potential of line becoming crimped or collapsing resulting in the exhaust port being clocked. Be sure to call Welch

technical service prior to start-up at 847-676-8800 if you have any questions.

Summary of Contents for DUOSEAL 1405B-01

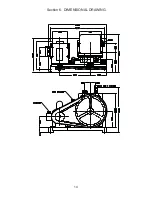

Page 14: ...Section 6 DIMENSIONAL DRAWING 14...

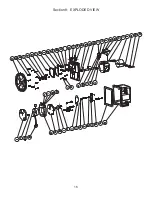

Page 16: ...Section 8 EXPLODED VIEW 16...