5

1.15 Electrical

Power

1.151 Power Source Review

Review the power source and the motor rating to be sure they agree in voltage, phase and frequency. On three-

phase applications the direction of rotation of the motor must be considered. Make a momentary check rotation

at the time of power installation and wiring. Momentary backward rotation of the pump is not harmful. Check the

layout drawings for proper direction of rotation.

CAUTION

Make certain the power settings on the pump match your power

source before attempting to operate the pump

1.152 Overload

Protection

Motor thermal overload protection is made available by the motor manufacturer as an aid to minimizing motor

failure. Overload protection is a standard feature on all single-phase 60Hz motors. Single-phase motors will

normally have automatic overload protection. Motors of 1-1/2 horsepower or larger supplied with DUOSEAL

pumps contain no overload protection. Installations of such equipment must comply with local electrical codes

which dictate appropriate starter and protection devices. It is strongly suggested that you familiarize yourself

with the protection supplied with your motor so that you may react accordingly in the event of an emergency.

Automatic reset protection is designed to reset itself after a predetermined cooling period. If the fault to the drive

remains unaltered, the motor will cycle on and off until the fault is corrected. The motor data plate will indicate the

presence of thermal protection.

1.16

Vacuum Connections (See Accessory Section in back of this manual.)

1.161 Choice of Connections

The choice of connections and fi tting can have a very marked effect on the pumping speed at the vacuum

chamber. Any connection placed between the pump and the chamber creates an impedance to the fl ow of gas.

This is particularly true at low pressures in the millitorr range where the gas fl ow is substantially molecular in

character. The gas fl ow is then dependent upon the kinetic activity of the molecules to bring it to the intake of the

pump.

1.162 The Effects of Conductance

It has been shown that the conductance of a tube is proportional to the cube of its radius and inversely

proportional to its length. Therefore it is imperative that the connecting lines be as large in diameter and as short

in length as practical. For best results the diameter of the connecting tube should be at least as large as the

diameter of the pump intake. To avoid a large reduction in pumping speed at the vacuum chamber, it is clear that

the conductance of the line must be considerably greater than the speed of the pump.

1.163 Metal

Joints

If metal piping or tubing is used, it is preferable to solder or braze all of the connections. Where threaded joints

must be used, coat the threads with LocTite® Thread Sealant with PTFE, or Leak Lock and screw together tightly.

Flanged connections with elastomer gaskets make excellent demountable joints. Modular vacuum piping and

fi ttings are now extensively used.

1.164 Rubber

Tubing

Joints

Where metal tubing is used between the system and the pump intake, joints can be make by butting the ends of

the two sections together in a short section of vacuum hose. Worm-screw band clamps are useful for securing

the hose to the tubing. Whatever the joint you choose to use, cleanliness should be of utmost importance.

1.165 Valves and Stopcocks

Metal valves or stopcocks may be used in the connecting line between the system and the pump to provide a

means of isolating the pump from the system. To minimize the impedance of fl ow, the valve openings should be

as large as possible. Lubricate the rotating plug of the stopcock with a fi lm of vacuum grease suffi ciently thick

enough to prevent seizure.

Summary of Contents for DUOSEAL 1405B-01

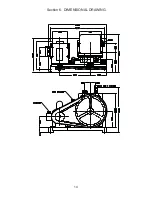

Page 14: ...Section 6 DIMENSIONAL DRAWING 14...

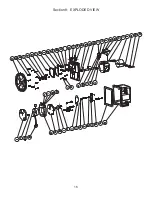

Page 16: ...Section 8 EXPLODED VIEW 16...