10

3.203 Forced Oil Flushing Procedure

1. Check the oil level, if the oil level is well above the fill mark, (This may indicate either the pump has been

overfilled with oil or has ingested a liquid or a large amount of vapor water or organic solvents.)

Please go to step 2. If the oil level is even with the fill mark and you do NOT suspect corrosive gases or

particulates (hence forth called contaminants) ingested have damaged the mechanism, run the pump for

15 minutes to allow the pump oil to warm up before going to step 2.

2. Turn off motor for the vacuum pump. Drain the oil into a clear plastic container (may need pliers to open

drain valve). Look for contaminations settling to the bottom of container. If you see contaminants, you

will need to repeat step 3 through 5 several times until the oil comes out clear. The oil you drained from

the pump came from the oil case only. There may be contaminants in the pumping mechanism.

To be sure all contaminants have been removed, the pump mechanism needs to be flushed.

3. Make sure the belt guard is installed before proceeding further. Attach a short hose to the drain valve

which runs into a clear plastic container.

4. Flushing the pump is carried out by adding a cup of DUOSEAL vacuum pump oil through the intake port

(IN) while the pump is turned on for 15 to 20 seconds. While adding the pump oil, the palm of your hand

is placed lightly over the exhaust port (OUT). Look for water coming out of the drain. Turn off the pump.

5. Repeat step 4 until clean oil comes out of the drain hose.

6. Close the drain valve and fill the pump with the amount of DUOSEAL vacuum pump oil your pump needs.

7. Plug the intake (IN) port with a rubber stopper. Turn the pump on and run the pump for 10 minutes.

Close the gas ballast.

8. Check the vacuum reading of the pump by connecting a thermocouple gauge tube to the pump’s intake.

If the pump is running nearly as good as when it was new, the total pressure reading you will read on

wither of these two gauges will be at least 10 micron.

A simple way to connect the gauge tube to the pump is to run the threaded tip of tube through a hole in a rubber

stopper. Use pump oil as a lubricant for inserting the tube. The stopper chosen should be bigger than the outer

diameter of the intake flange.

3.204 Refilling The Pump

After you are satisfied that the pump has been thoroughly flushed, refill the pump by pouring new DUOSEAL oil

into the exhaust port. Fill to the indicated level and start the pump with the intake closed. A gurgling noise is

characteristic when high pressure air is drawn through the pump. It should disappear quickly as the pressure

within the pump is reduced. If gurgling continues, add sufficient additional oil through the exhaust port until

gurgling ceases.

3.30

Shaft Seal Replacement

To replace the shaft seal of a pump, drain the oil and remove the pump pulley and key. Remove the screws

securing the old seal and pry it loose with a screwdriver or similar wedge, being careful not to mar the surface

of the pump body against which the seal fits. Discard the seal and its gasket, inspect all surfaces and repair any

damages with a fine abrasive stone. Wipe all sealing areas clean and place a film of DUOSEAL oil on both the

shaft and the inside bore of the new shaft seal. Using a new gasket, carefully slide the new seal into position and

center it on the shaft. It is not necessary to apply any sealant to the gasket. Tighten the mounting screws

uniformly and refill the pump with DUOSEAL oil. Follow instructions included in repair kit.

Summary of Contents for DUOSEAL 1399B-01

Page 14: ...14 Section 6 DIMENSIONAL DRAWING ...

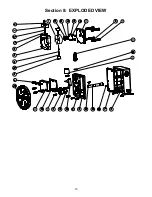

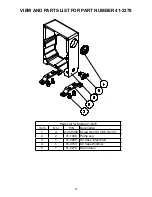

Page 16: ...16 Section 8 EXPLODED VIEW ...