19

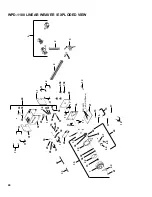

AMPLITUDE (WEAVE):

Continuously adjustable up to a 2" (51 mm) maximum weaver stroke.

CARRIAGE TRAVEL SWITCH:

Provides

FORWARD/STOP/REVERSE

direction control.

DIGITAL READOUT:

Three tractor display modes exist.

a) PRESET SPEED -

Displayed when the

CARRIAGE TRAVEL SWITCH

is

OFF

or motion is

halted by a motor overload condition.

b) CONTINUOUSLY MEASURED SPEED -

Displayed when the

MODE SELECTOR SWITCH

setting is

RUN

or

NO WEAVE

. (This will be the same as the Preset Speed.)

c) SAMPLED SPEED -

The tractor motion alternates between moving at the Preset Speed and

stopping when the

MODE SELECTOR SWITCH

is set to

STEP

or

STOP ON DWELL

. This

is referred to as “stepping” the tractor. To avoid having the display continuously fluctuate

between the zero speed and the actual speed, the readout measures the travel speed near

the end of each tractor step. This speed is then displayed until another sample is taken at

the end of the next tractor step. This provides a stable display of the measured travel speed.

(This will be the same as the Preset Speed.)

Factory settings of 120 Volt machines are set to in/min, 240 and 42 Volt machines are set cm/min.

LEFT AND RIGHT DWELL:

The left and right dwell controls have a 0-3 second adjustment range.

MODE SELECTOR SWITCH:

Four welding modes are available.

SPEED CONTROL (TRACTOR):

Sets the tractor speed from 2-120 in/min (5.1-304.8 cm/min).

START/STOP:

This enables/disables all tractor and weaver motion.

STEERING:

The three-turn steering knob has a +/- 2" (51 mm) range.

WEAVE SPEED CONTROL:

Sets the weave speed from 0-100 in/min (0-254 cm/min).

WELD CONTACT:

Opens/closes a pair of independent 1 Amp contacts (pins A & B and C & D) at the weld

contactor receptacle.

NOTE:

A safety interlock will automatically open the weld contacts if the motor overload

protection halts machine motion. Clear the overload by turning the carriage travel

switch to off. Resetting the overload fault will not cause the contacts to automatically

reclose. Use the weld contact switch to restart the welder after clearing the overload.

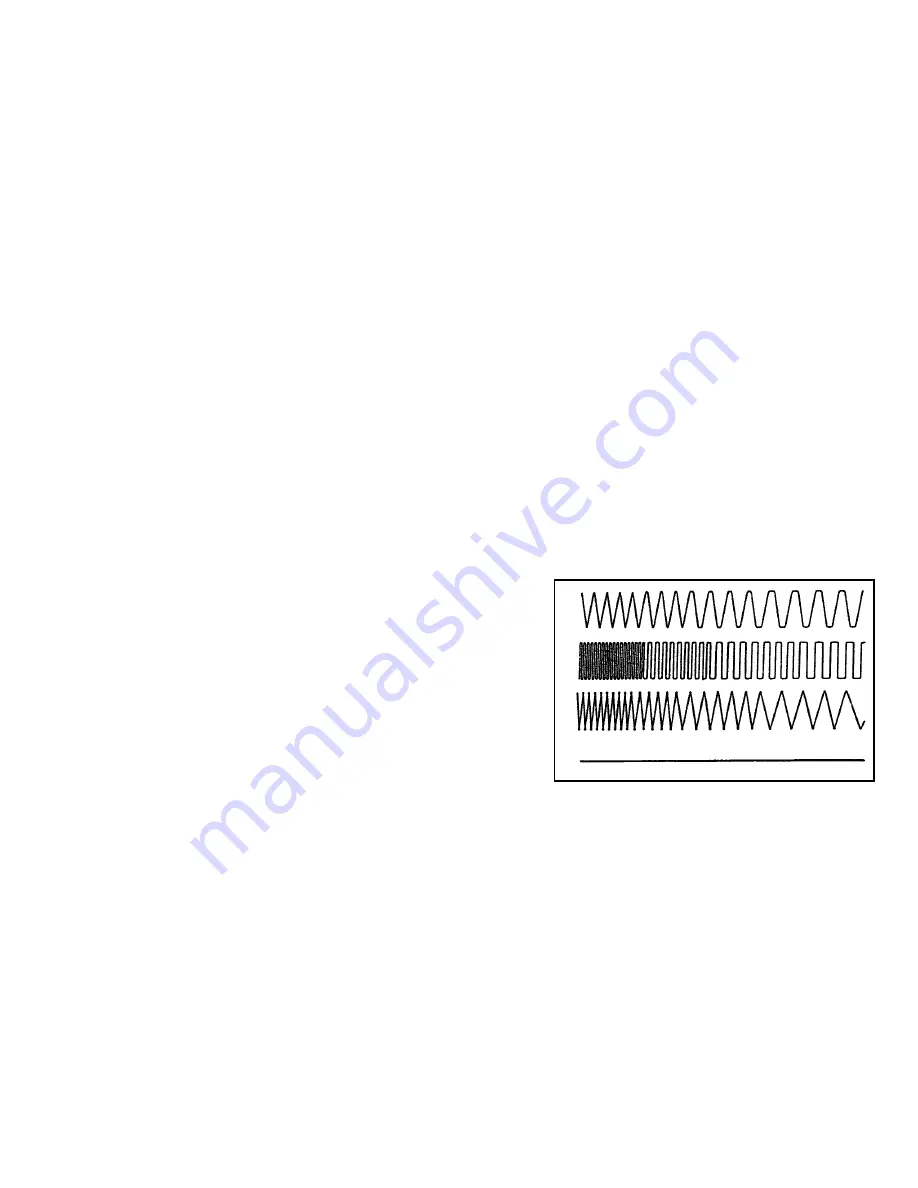

1) RUN

- In this mode, power to the drive unit is always on

and the machine travels continuously both during weave

and dwell. Weave speed and dwell time both affect the

weave pattern.

2) STEP

- The unit travels only during dwell and stops during

the weaver cross stroke. Changing weave speed does not

effect the weld pattern-dwell time does.

3) TRACTOR STOP ON DWELL

- The tractor travels during

the weave stroke; the tractor and weaver stop during dwell.

4) NO WEAVE

- In this mode oscillation is stopped. Only the

tractor is powered. This mode is used for stringer passes.

1

2

3

4

WEAVER CONTROL MODULES, CONT’D.