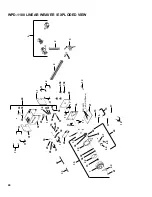

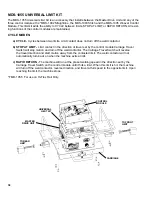

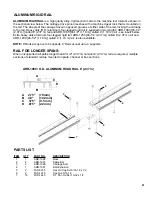

2. Secure Carriage on Rail

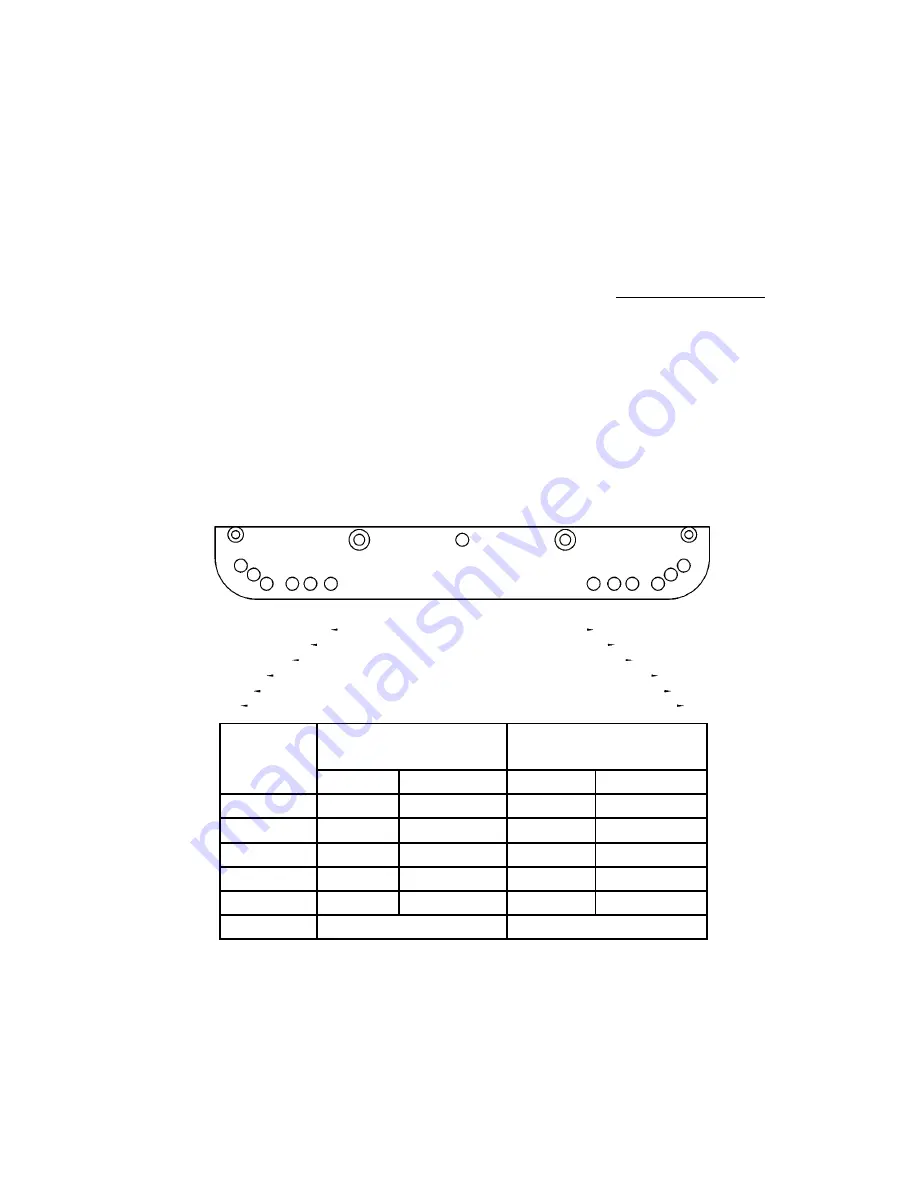

A. Select the correct pair of holes on each side of the carriage for the rail diameter being used (see chart,

below). If the wheels are not attached to the correct set of holes, remove the wheel brackets and bolt

them in selected holes. Tighten the bolts until the brackets are snug but still free to rotate.

B. Loosen the adjustment knob to separate the two halves of the split carriage. Loosen and turn the clutch

knob counterclockwise to put the drive in the declutched position.

C. Place the carriage on the ring rail with the wheels in the rail grooves. Close the cam handle and move

the carriage back and forth a few inches. The wheels on their mounting brackets will align themselves

correctly with the rail grooves.

D. Verify that wheels are properly aligned, then tighten the wheel mounting bolts to lock them in position.

Rotate the clutch knob clockwise to engage the drive pinion with the rack.

E. Verify that pinion is properly engaged in rack. The correct wheel position will provide a minimum of 1/8"

(3.175 mm) engagement between the drive pinion and the gear rack.

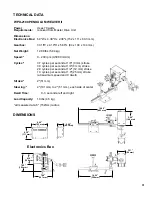

3. Position and Clamp Welding Gun

Secure welding gun in the all-position clamp located on the end of the height control mechanism. Arrange

cables so that they do not interfere with the movement of the machine and secure in the cable anchor at

the back of the machine.

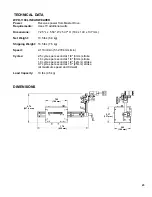

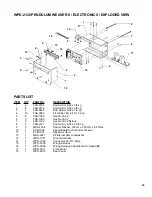

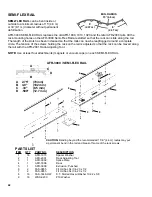

DETAILED SETUP

1. Install Rail

The Tube Carriage is designed for use with Bent Rigid Rail (BRR) or Ring Rail. The exact outside diam

-

eter (OD) of the work piece, including coating, must be known when ordering rail. Minimum pipe OD is

9 inches (229 mm). Rail is custom bent for each OD and features adjustable feet to accommodate pipe

ovality and deviations in coating thickness.

A

B

C

D

E

F

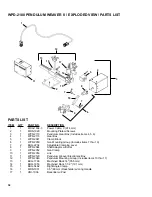

Notes:

1. Chart values are for reference only

2. Pinion height may need to be adjusted for some rail or pipe sizes.

Carriage

Wheel

Hole Set

BRR-1210

Rail ID

Pipe OD

in

mm

in

mm

A

20 - 25

500 - 635

9 - 21

230 - 530

B

23 - 35

585 - 890

12 - 31

300 - 790

C

30 - 44

760 - 1120

18 - 40

455 - 1015

D

41 - 60

1040 - 1525

29 - 54

735 - 1375

E

75 - 174 1905 - 4420

64 - 170

1625 - 4320

F

flat rail

flat rail

37