50

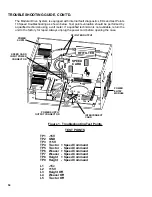

TROUBLESHOOTING GUIDE, CONT’D.

PROBLEM

POSSIBLE CAUSE TEST BASE SYSTEM TEST PROCEDURE / REMEDY

Faulty motor.

2E

Disconnect the motor leads. Apply 2 to 8 volts DC across the motor

leads. Verify that the motor spins.

Faulty control

module, speed card,

or motor.

2F

Install one voltmeter lead on TP4 and the other lead on TP5. Turn

on the main power. Set the control module for continuous forward

tractor motion. If the control module has any type of motion enable

switch, turn it to enable. Rotate the tractor speed control knob while

observing the voltmeter output. It is possible to vary this voltage

between 0 and 8 Volts DC using a good

control module.

a) If the voltage does not vary, replace the control module card.

b) If the voltage does vary, turn the machine OFF and then ON

using the main power switch. Observe LED L5. L5 should light

for a moment or two during power-up while safety circuits hold

the tractor OFF until full power is reached. L5 should then turn

off indicating power has been applied to the motor and motion

should start.

1) If the L5 never lights, replace the speed card.

2) If the L5 turns on, turns off, and then turns on again, check for

shorted motor connections. If none are found, replace the speed

card.

3) If the L5 turns on and then stays on, check that the control

module is set up as defined above and retest 2F. A second

failure indicates a bad speed card.

4) If L5 turns on and then off and the motor doesn’t start turning,

turn the tractor speed up. If the motor does not begin to turn,

check the motor to speed card wiring for faults and repair as

needed. If the motor still fails to turn, replace the speed card.

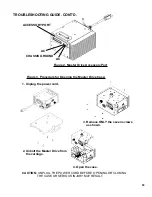

Stitch mode on

control module

does not work.

Bad control module

or bad tractor speed

card.

3A

If the speed and direction work in CONTINUOUS mode, then the

control module is bad.

If the speed and direction do not work in CONTINUOUS mode,

go to test 2A.

Tractor moves

a short distance

and then stops.

High Frequency

Interference.

4A

Turn off the welder or plasma unit. The unit should operate normally.

Carrying too much

weight.

4B

Verify the load placed on the carriage does not exceed the factory

rating.

Brake is dragging.

4C

Remove the unit from the track and set the controls to forward

tractor motion. If the pinion motion stops after a short time, or a

check shows that the weight placed on the machine is not excessive,

then the problem is most likely brake related. Return the machine for

repair.