51

TROUBLESHOOTING GUIDE, CONT’D.

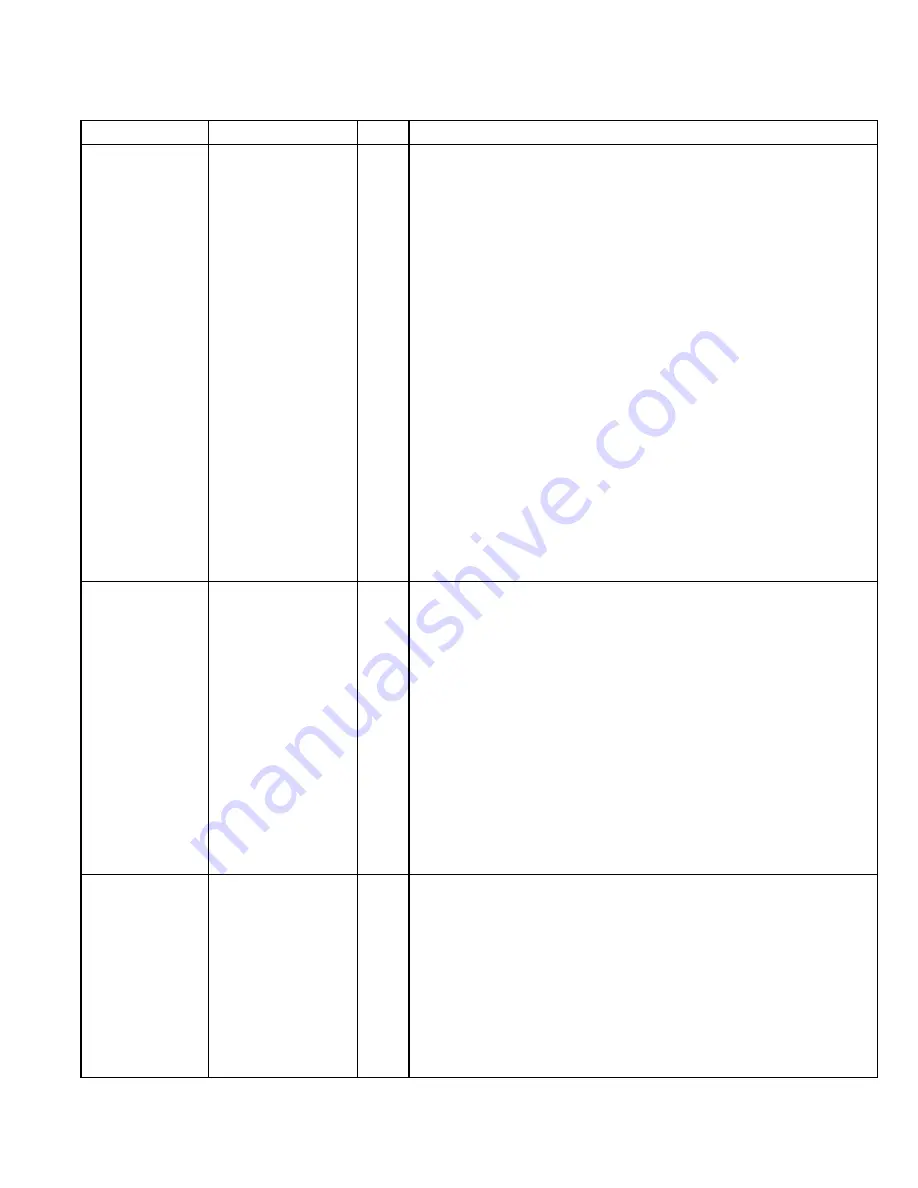

PROBLEM

POSSIBLE CAUSE TEST BASE SYSTEM TEST PROCEDURE / REMEDY

Linear Weaver

does not move.

Bad control card or

bad weaver.

5A

Set the weaver control module MODE SELECT switch to NO

WEAVE and the START/STOP switch to START. Turn the weave

speed up to max. Continuously move the STEERING CONTROL

knob clockwise and then counter clockwise. This should cause the

weaver arm to move back and forth.

a) If the arm moves, proceed to step 6A.

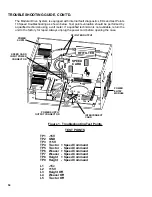

b) Unbolt and disconnect the weaver box from the modular drive

accessory port (see Figure 2). Open the master drive case (see

Figure 3). Install one voltmeter lead on TP6 and the other lead

on TP7 (see Figure 1). Turn on the unit.

Set the weaver control module MODE select switch to RUN (no

weave) and the START/STOP switch to START. If the voltage

reading is less than 2 V DC, adjust the STEERING pot on the control

module until the reading is greater than 2 V DC.

1) If the pot adjustment will not produce at least 2 V DC on the

voltmeter, replace the control module card.

2) If the voltmeter displays above two volts, with or without pot

adjustment, replace the weaver speed card.

Linear Weaver

moves in one

direction only or

moves erratically.

Bad control card,

bad weaver speed

card, or loose set

screws on the

servo pot’s flexible

coupling (coupling is

used on WPD-1000

only).

6A

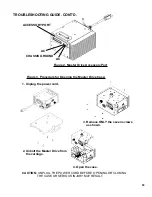

On the WPD-1000 linear weaver only, tighten the set screws on

the servo potentiometer’s flexible coupling. This part can be

accessed by removing the WPD-1000 linear weaver’s side panel

that is located closest to the clutch screw.

Set the weaver control module MODE SELECT switch to NO

WEAVE and the START/STOP switch to START. Turn the WEAVE

SPEED up to max. Continuously move the STEERING CONTROL

knob clockwise and then counter clockwise. This should cause the

weaver arm to move back and forth.

a) If the weaver moves in one direction only, the weaver speed

card is bad.

b) If the arm weaves but the control module does not function

correctly, the control module is bad.

Pendulum

Weaver

moves

in one direction

only or moves

erratically.

Bad control card or

bad speed card.

7A

Set the weaver control module MODE SELECTOR switch to NO

WEAVE and the START/STOP switch to START. Turn the

WEAVE SPEED up to max. Continuously move the STEERING

CONTROL knob clockwise and then counter clockwise. This

should cause the weaver arm to move back and forth.

a) If the weaver moves in one direction only, the weaver speed

card is bad.

b) If the arm weaves but the control module does not function

correctly, the control module is bad.