ENGLISH

OM-235 816 Page 5

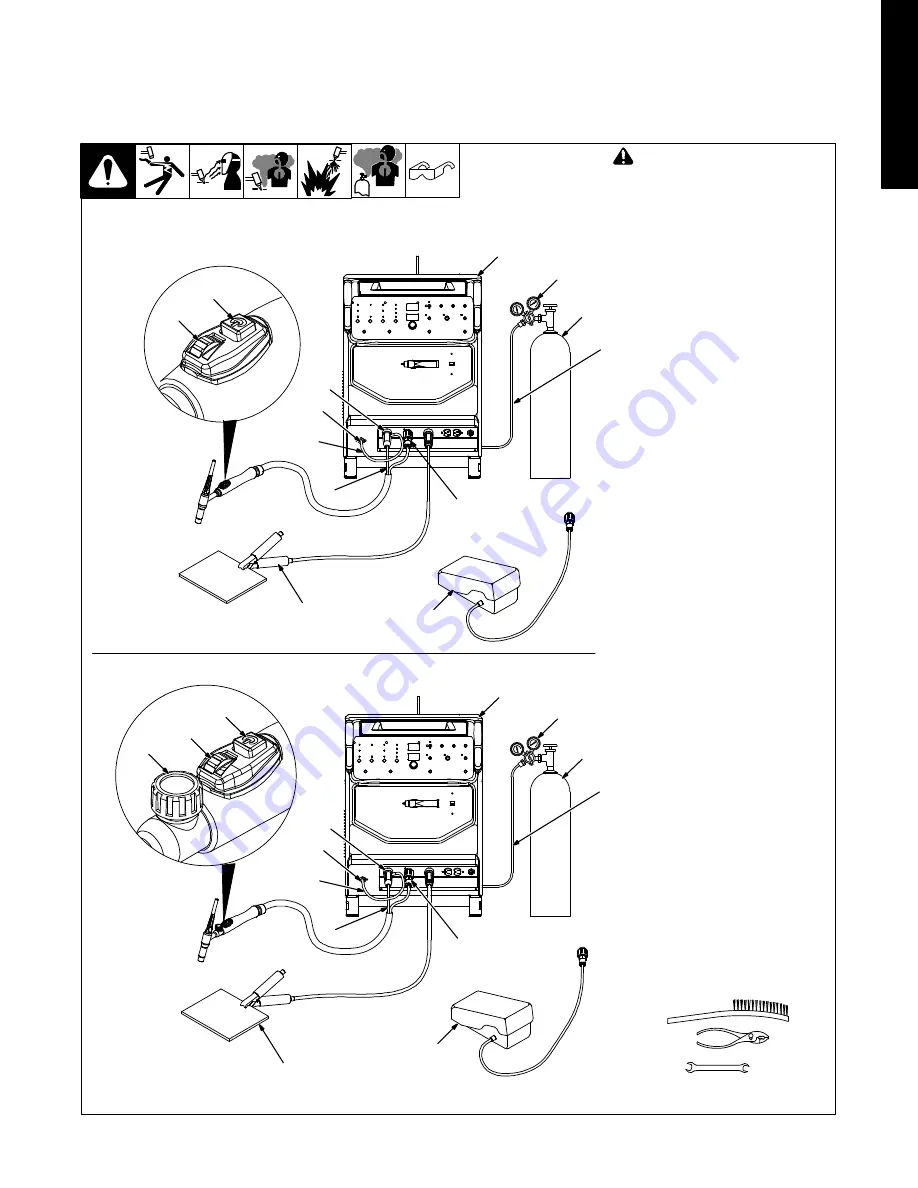

3-3. Connecting Torch

A. Connecting Torch With One-Piece Cable

!

Turn Off welding power source

power before installing torch.

Obtain the following hose:

1

Gas Hose With 5/8-18 Right-Hand

Fittings

2

Gas Cylinder

3

Regulator/Flowmeter

4

Welding Power Source

Connections:

5

International Style Connector

6

Gas Fitting

7

Short Gas Hose

8

Torch Power Cable

9

14-Pin Plug

Connect torch power cable to interna-

tional style connector (see Section 3-2).

Connect short gas hose to international

style connector.

Connect international style connector to

weld output terminal.

Connect remaining end of short gas

hose to gas fitting.

Connect 14-pin plug to matching recep-

tacle on power source.

10 Work Clamp

Connect work clamp to clean, paint-free

location on workpiece, close to weld.

Use wire brush to clean weld joint area.

Operation:

11 Contactor Control Switch

Use switch to turn torch on/off.

12 Amperage Control Dial

Turn dial to control amperage.

Operating Torch Gas Valve:

13 Torch Gas Valve

Valve controls gas preflow and postflow.

Open valve on torch just before welding.

Preflow is used to purge the immediate

weld area of atmosphere.

Postflow is required to cool tungsten and

weld, and to prevent contamination of

tungsten and weld. After welding, leave

valve open about 1 second for every 10

amperes of weld current. Close valve on

torch when postflow is finished.

14 Foot Control

Use of customer supplied foot control is

optional.

Tools Needed:

5/8, 7/8 in.

3

Torch Without Gas Valve

7

6

Torch With Gas Valve

.

If applicable, install high-frequency unit.

1

2

4

5

8

9

11

12

10

14

805 061-A

11

12

13

10

14

3

1

2

4

7

6

5

8

9

805 062-A