OM-235 816 Page 6

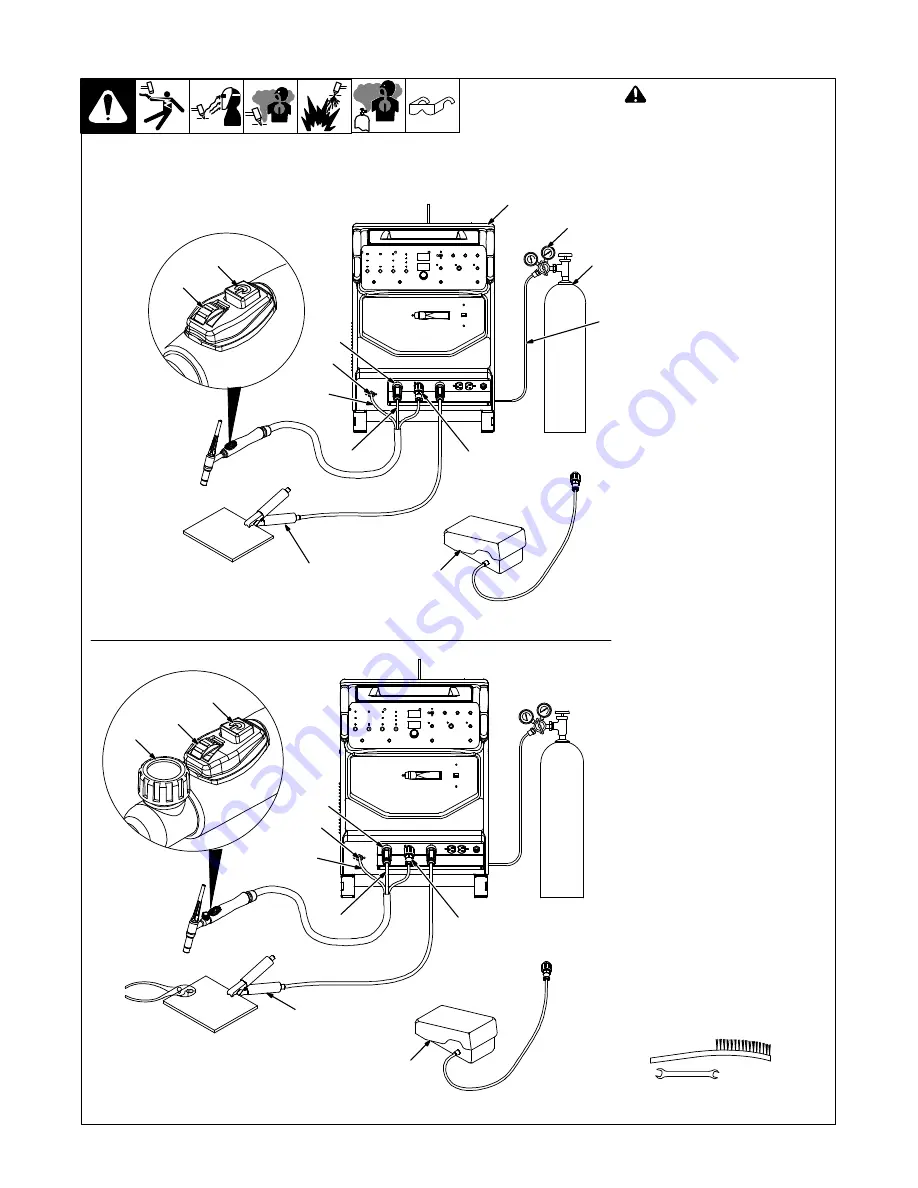

B. Connecting Torch With Two-Piece Cable

805 064-A

!

Turn Off welding power source

power before installing torch.

Obtain the following hose:

1

Gas Hose With 5/8-18 Right-

Hand Fittings

2

Gas Cylinder

3

Regulator/Flowmeter

4

Welding Power Source

Connections:

5

International Style Connector

6

Gas Fitting

7

Torch Gas-In Hose

8

Torch Power Cable

9

14-Pin Plug

Connect torch power cable to interna-

tional style connector (see Section

3-2).

Connect international style connector

to weld output terminal.

Connect gas-in torch hose to gas

fitting.

Connect 14-pin plug to matching re-

ceptacle on power source.

10 Work Clamp

Connect work clamp to a clean, paint-

free location on workpiece, close to

weld area.

Use wire brush to clean weld joint

area.

Operation:

11 Contactor Control Switch

Use switch to turn torch on/off.

12 Amperage Control Dial

Turn dial to control amperage.

Operating Torch Gas Valve:

13 Torch Gas Valve

Valve controls gas preflow and post-

flow. Open valve on torch just before

welding.

Preflow is used to purge the immedi-

ate weld area of atmosphere.

Postflow is required to cool tungsten

and weld, and to prevent contamina-

tion of tungsten and weld. After weld-

ing, leave valve open about 1 second

for every 10 amperes of weld current.

Close valve on torch when postflow is

finished.

14 Foot Control

Use of customer supplied foot control

is optional.

Tools Needed:

5/8, 7/8 in.

Torch With Gas Valve

10

Torch Without Gas Valve

1

805 063-A

.

If applicable, install high-frequency unit.

11

12

11

12

13

3

2

4

7

6

5

7

6

5

8

9

10

14

14

9

8