OM-230 915 Page 1

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING

Tung_Grind 2010−03

Protect yourself and others from injury — read and follow these precautions.

1-1.

Symbol Usage

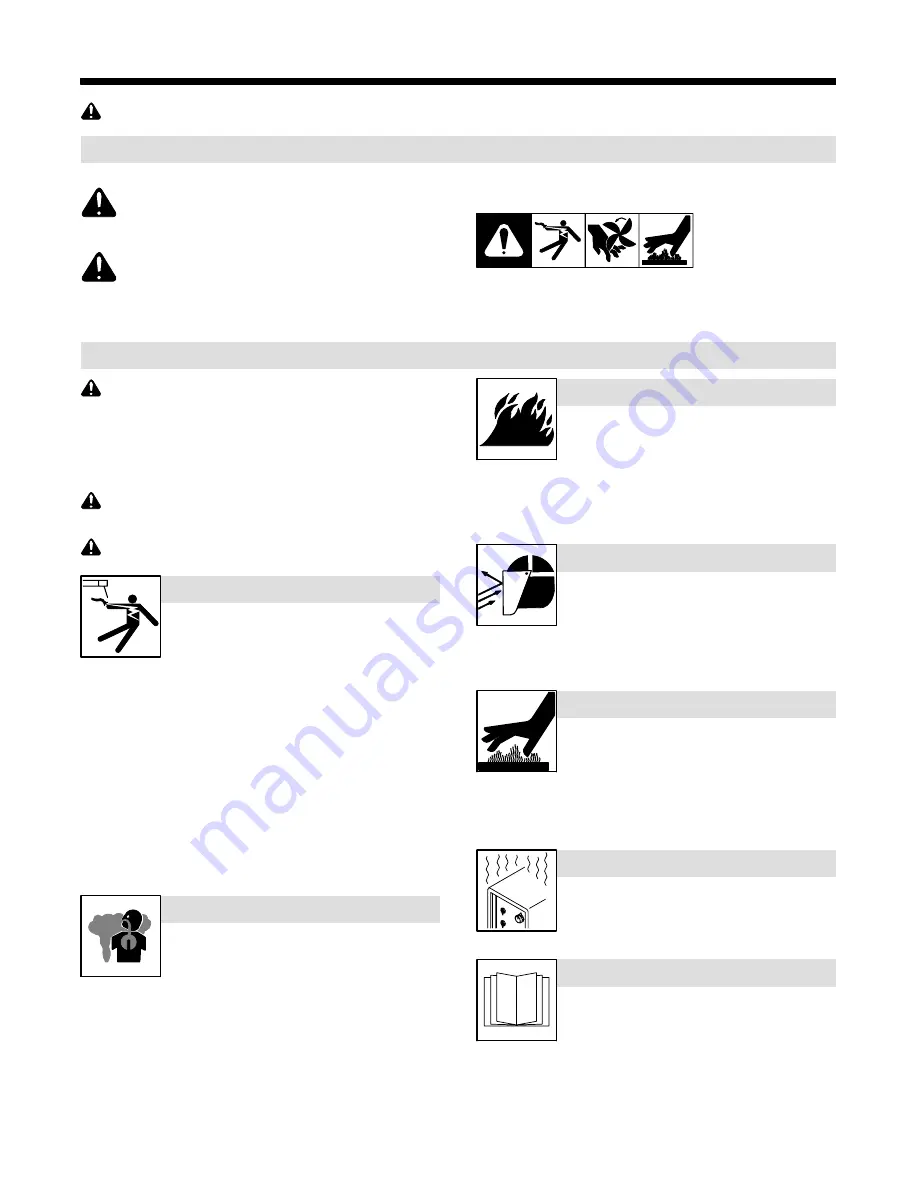

DANGER! − Indicates a hazardous situation which, if

not avoided, will result in death or serious injury. The

possible hazards are shown in the adjoining symbols

or explained in the text.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible

hazards are shown in the adjoining symbols or ex-

plained in the text.

NOTICE − Indicates statements not related to personal injury.

Indicates special instructions.

This group of symbols means Warning! Watch Out! ELECTRIC

SHOCK, MOVING PARTS, and HOT PARTS hazards. Consult sym-

bols and related instructions below for necessary actions to avoid the

hazards.

1-2.

Tungsten Grinding Hazards

The symbols shown below are used throughout this manual

to call attention to and identify possible hazards. When you

see the symbol, watch out, and follow the related instructions

to avoid the hazard. The safety information given below is

only a summary of the more complete safety information

found in the Safety Standards listed in Section 1-4. Read and

follow all Safety Standards.

Only qualified persons should install, operate, maintain, and

repair this unit.

During operation, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns. The input power circuit and

machine internal circuits are also live when power is

on. Incorrectly installed or improperly grounded

equipment is a hazard.

Do not touch live electrical parts.

Wear dry, hole-free insulating gloves and body protection.

Disconnect input power before installing or servicing this

equipment.

Properly install this equipment according to its Owner’s Manual

and national, state, and local codes.

Frequently inspect input power cord for damage or bare wiring −

replace cord immediately if damaged − bare wiring can kill.

Turn off all equipment when not in use.

Use only well-maintained equipment. Repair or replace damaged

parts at once. Maintain unit according to manual.

Keep all panels and covers securely in place.

Grinding produces dust. Breathing this dust can be

hazardous to your health.

GRINDING DUST can be hazardous.

Do not breathe the dust.

Use local exhaust (forced ventilation) to remove dust or wear an

approved respirator.

Grinding dust from thoriated electrodes contains low-level radio-

active material. Consider using tungsten containing ceria,

lanthana, or yttria instead of thoria.

Properly dispose of grinder dust in an environmentally safe way.

Read and understand the Material Safety Data Sheets (MSDSs)

and the manufacturer’s instructions for metals and consumables.

GRINDING can cause FIRE OR EXPLOSION.

Do not grind where flying sparks can strike

flammable material.

Protect yourself and others from flying sparks

and hot metal.

Be alert that sparks and hot materials from grinding can easily go

through small cracks and openings to adjacent areas.

Watch for fire, and keep a fire extinguisher nearby.

FLYING SPARKS can injure.

Wear a face shield to protect eyes and face.

Shape tungsten electrode only on grinder with

proper guards in a safe location wearing proper

face, hand, and body protection.

Sparks can cause fires — keep flammables away.

HOT PARTS can burn.

Do not touch hot parts bare handed.

Allow cooling period before working on equip-

ment.

To handle hot parts, use proper tools and/or

wear heavy, insulated welding gloves and

clothing to prevent burns.

OVERUSE can cause OVERHEATING

Allow cooling period; follow rated duty cycle.

Keep air holes free of dust; clean if necessary.

READ INSTRUCTIONS.

Read and follow all labels and the Owner’s

Manual carefully before installing, operating, or

servicing unit. Read the safety information at

the beginning of the manual and in each

section.

Use only genuine replacement parts from the manufacturer.

Perform maintenance and service according to the Owner’s

Manuals, industry standards, and national, state, and local

codes.