TitanMig 200D Operators Manual

Issue. A 1216

Gas Flow too high or too low

Check gas is connected. Set gas flow between 10-15 l/min.

Protect Weld Zone from wind & drafts

Moisture on the base metal

Remove all moisture from base metal

Contaminated base metal

Remove any paint , grease, oil & dirt

Contaminated MIG Wire

Use clear dry rust free wire only.

Gas nozzle worn or out of shape

Replace it

Missing or damaged gas diffuser

Replace it

Mig Torch O-ring missing or worn

Replace it

Wire stubbing

Holding the torch too far away

Bring torch closer to work piece. Stick out should be 5-10mm

Welding Voltage too Low

Increase Voltage

Wire Speed Too High

Decrease the wire speed

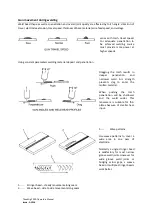

Lack of Penetration

Poor joint preparation

Material too thick. Joint preparation needs to allow access to bottom of groove

Contaminated base metal

Remove any paint , grease, oil & dirt

Lack of Fusion

Contaminated base metal

Remove any paint , grease, oil & dirt

Not enough Heat input

Increase voltage range / adjust wire speed

No wire Speed

Wrong Mode selected

Check that the selector switch is set to MIG position

Inconsistent Wire Feed

Adjusting wrong dial

Adjust Wire Speed & Voltage for Mig. Amp dial is used for MMA & TIG

Wrong Polarity

Select the correct polarity for the wire being used

Incorrect Wire Speed

Adjust Speed setting

Voltage Setting Incorrect

Adjust Volt setting

Torch too long

Replace with shorter gun

Contact tip worn / wrong size

Replace with correct type

Liner worn or clogged

Replace with new liner

Wrong size liner

Replace with correct type

Blocked inlet or outlet guide

Clean or Replace

Incorrect drive roller

Fit correct type for wire being used

Worn drive roller

Replace with new

Drive roll pressure to high

Reduce Drive roll pressure

Too much tension on wire spool hub

Reduce the spool hub tension brake

There is output current when pushing the torch trigger to feed gas, but the wire feeder does not work.

The control cable of the wire feeder is broken

Get it repaired or replaced

The wire feeder is clogged.

Unclog it.

The wire feeder fails.

Repair it.

The control PCB or wire-feeder power PCB inside

the machine fails

Replace it.