6

Putting into operation

Spare part replacement

• Evaluate welding temperature: direct observation for transparent PE material, speed and temperature will be

appropriate if welding mark is flat and in transparent glass form; temperature will be too high and speed be

too slow if mark is heavily broken; temperature will be low and speed be fast if mark is not transparent and

with white. For opaque material, observe if there is obvious welding mark, also tensile test can be made after

complete cooling.

• Flatly and straightly trim the weld edges and frontage faced, with lower left and upper right overlapped. The

overlap width is 100mm.

• After temperature and speed have been determined, insert material to be welded between the two pressure

rollers, make machine body parallel with edges of base materials and engage press lever handle for proper mo-

tion. Check the welded seam (welded bead/weld path). If required, correct the speed with the

Speed control

knob (6).

• When welding will be ended, timely press lever handle to disengage upper and lower pressure roller to prevent

rubber wheel damage for long duration.

• Excessive temperature high and low may occur because of

thermal inertia. On this condition, temperature deviation may be

compensated by speed regulation on a small degree.

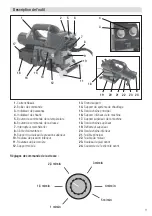

• A “T” shape overlap is formed between welded and additional

material. Welding method is shown as figure below, tightly butt

the overlap head of hot wedge against weld mark, and beveling

cut length is approximately 100 mm.

•

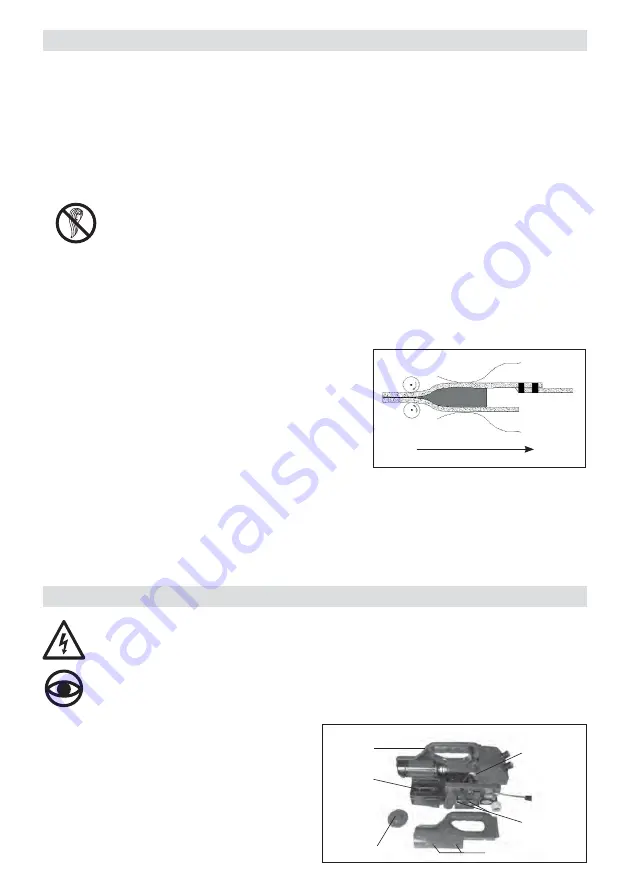

Replacement of hot wedge assembly

Remove the front end covering, remove the 4-M4

screws and tapping screw, remove a half housing,

release 4-M3 screws, remove the 2-M5 screws

that connect heating support and slide carriage,

remove hot wedge and replace with a new one, and

reassemble the complete machine (shown in the

following figure).

Note:

conform to color on wiring.

Run direction

While working on the open system avoid wearing garments such as shawls, scarves and ties.

Long hair must be tied or protected by headgear.

Before opening it, remove the tool from the mains.

Tapping

screw

4-M5

installation

screws

4-M4

2-M5

4-M4

Front end

covering

The machine may only be used by

qualified specialists

or under

their supervision.