~

fig.36

Twine Retainer Tension

Adjust twine tension spring to distance

Q (fig.

32).The

measuring gauge along side the spring

gi,ves the correct measure. Adjust discrepan-

eies with holt 12.

Distance R is set as fellows end shown in fig.33:

glocken lock nut 1 by tour full turns. Slacken

holt 2 until leGt spring 3 is unloaded. Run down

holt 2, first till it contacts leGt spring 3, then by

exactly 3'/2 turns. This gives spring 3 a pre-

loading

of 5 mm. Finally fighten lock nut 1

again.

Adjusting the Twine Flicker

Trip knotters

(see fig. 9), turn flywheel in

direction of arrow until flicker 4 (fig. 34) stops

in forward position. Distance S must now be

1-2 mm. If not, glocken lock nuts 5 end turn set

screw 6 as required end secure again.

Twine Stop Spring

Spring 7 (fig. 35) must rest under tension against

nase 8 of twine guide plate.

If

necessary, bend

spring 7 as required.

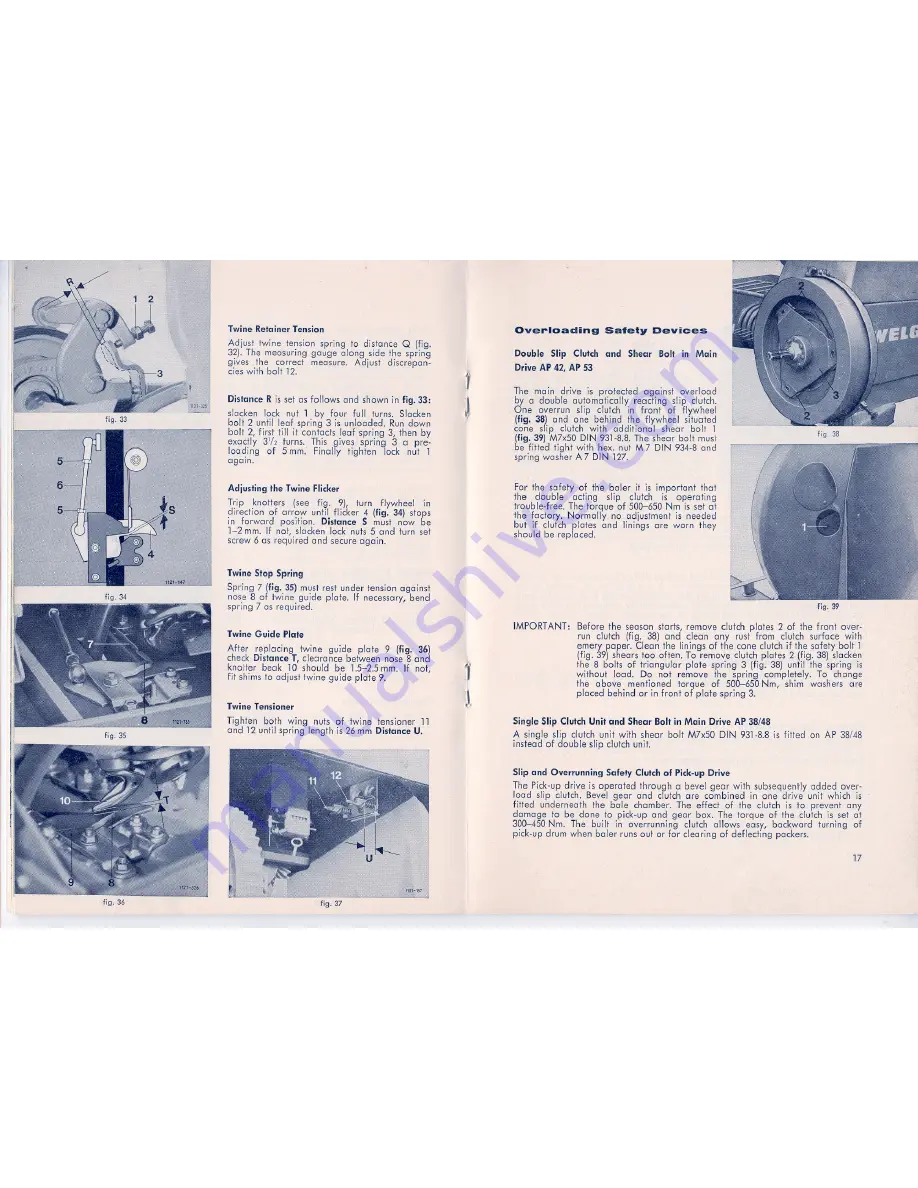

Twine Guide fiale

After replacing twine guide plate 9 (fig.

36)

check

DistanceT, clearance between nase 8 end

knotter heck 10 should be

1.5-2.5

mm. If not,

fit shims to adjust twine guide plate 9.

Twine Tensioner

Tighten both wing nuts of twine tensioner 11

end 12 until spring length is 26 mm Distance U.

fig. 37

j

~~

~

~

Overloading

Safety

Devices

Double Slip Clutch and

ShearBolt

in Main

Drive

AP 42, AP 53

The mein drive

is

protected

against overload

by d double automatically

reacting slip clutch.

. One

overrun

slip clutch in front

of flywheel

(fig.

38) end one behind ihe flywheel

situated

cone slip clutch with

additional

shear holt

1

(fig.

39) M7x50 DIN 931-8.8. The shear holt musr

.be fitted light with hex. nut M 7 DIN

934-8

end

spring washer A 7 DIN 127.

For the safety of the baler it is important

thaI

the

double

acting

slip

eluIeh

is

operating

trouble-free. The torque of

500-650

Nm is se,t at

the factory. Normally

no adjustment is needed

hut if clutch plates end linings are warn they

should be replaced.

IMPORTANT:

fig. 38

fig..39

Before the sepsen starts, remove clutch plates 2 of the front. over-

run clutch (fig. 38) end clean any fUgt from

clutch surface with

emery paper. Clean the linings of the cone eluIeh if the safety holt 1

(fig. 39) shears tao offen. T0 remove clutch plates 2 (fig. 38) glocken

the 8 halts of triangular

pfote spring 3 (fig. 38) until the spring is

without

load.

Do not remove the spring completely.

To chonge

the above

mentioned

torque

of

500,...650Nm, shim washers are

placed

behind or in front of plate spring 3.

Single Slip Clutch Unit and Shear Bolt in Main Drive AP

38/48

A single slip alutch unit with shear holt

M7x50

DIN

931-8.8is

fitted on AP 38/48

instead of double slip clutch unit.

Slip and Overrunning

Safety Clutch of Pick-up Drive

The Pick-up drive

is

operated through abevel

geer with subsequently added over-

load slip oIutch. Bevel geer end eluIeh are combined in one drive unit

which

is

fitted

underneath

the ba,le chamber. The effect of the clutch is to prevent any

damage to be düne to pick-up end geer box. The torque of the eluIeh is set at

300-450

Nm. The built in overrunning

cluleh pIlaws easy, backwardturning

of

pick-up drum when baler runs out or für clearing of deflecting packers.

17

Summary of Contents for AP 38

Page 1: ......