fig.42

fig. 43

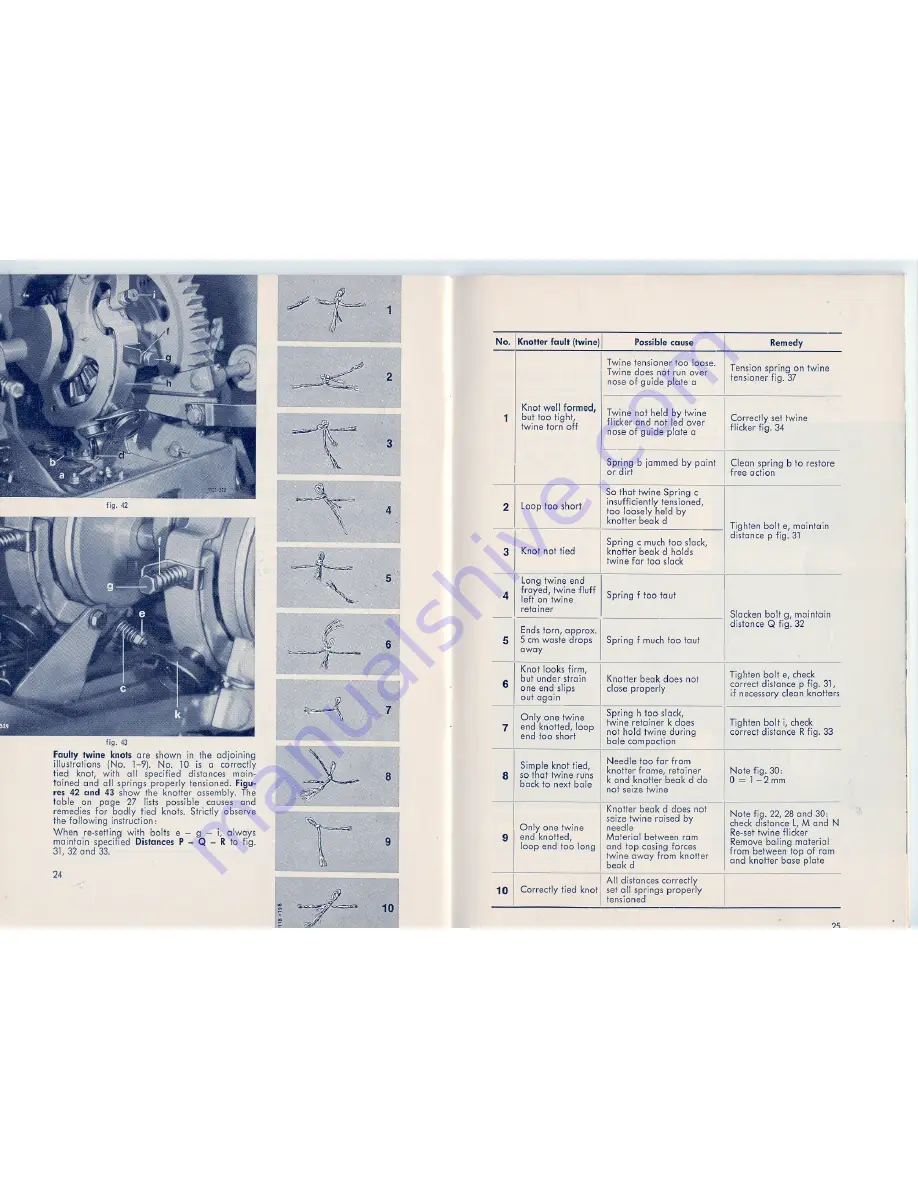

Faulty twine knots are shown in the adjoining

illustrations

(No.

1-9). No.

10 is a correctly

lied

knot, with

oll specified

distances main-

tained end all springs properly tensioned. Figu-

res 42 and 43 show the knotter assembly. The

fable

on

page

27

lists possible

causes end

remedies tor badly lied knots. Strictly observe

the following

instruction:

When

re-setting with bolts e -

9 -

i, always

maintain specified Distances P

-

Q

-

R to fig.

31,32 end 33.

24

('

Remedy

~

No.!

KnoHer fault (twine) I

Possible cause

I

Twine tensioner too loose.

Twine does not run over

nose of guide pfote a

1

Knot weil forrned,

but too fight,

twine tom off

Tension spring on twine

tensioner fig. 37

1

!

2

Loop too short

I

Correctly set twine

I

flicker fig. 34

Spring b jammed by point

I

Clean spring b to restore

or dirt

free action

Twi.ne not held by twine

flicker end not led over

nose of guide plate a

So thaI twine Spring c

insufficiently tensioned,

too loosely held by

knotter beak d

Spring c much too slack,

knotter beak d holds

twine far too slack

",

3

Knot not lied

Knotter beak does not

dose properly

Spring h too slack,

twine retainer k does

not hold twine during

bole compaction

Needle too far frorn

knotter frame, retainer

k end knolfer beak d do

not seize twine

Knotter beak d does not

seize twine raised by

needle

Material between rom

I

'

end top casing forces

twine away from knotter

beak d

I

I

All distances correctly

10

Correctly lied knot

I

set ',8'" springs

properly

tensloned

6

Knot looks firm,

but under strain

one end 'slips

out again

7

Only one twine

end knotted, loop

end too short

8

Simple kn?t lied,

so thai twlne runs

back to next bole

9

Only one twine

end knotted,

loop end too long

Tighten bolt e, maintain

distance p fig. 31

Slacken bolt g, maintain

distance Q fig. 32

Tighten bolt e, check

correct distance p fig. 31,

if necessary clean knotters

Tighten bolt i, check

correct distance R fig. 33

Note fig. 30:

0 = 1 - 2 mm

Note fig. 22, 28 end 30:

check distance L, M end N

Re-set twine flicker

Remove ba,ling material

from between top of rom

end knotter base pfote

'J'\

Long twine end

4

I

frayed, twine fluff

I

S

.

f t

t

t

left on twine

pnng

00 au

reta'iner

Ends tom, approx.

5

I

5 cm weste drops

I

Spring f much too taut

away

Summary of Contents for AP 38

Page 1: ......