Preparing

tor

Work

Balersare thoroughlytested and carefull

r

lubricated before leaving our werks and

are ready tor immediate service at fu,l capacity when observing the following

instruetions.

4

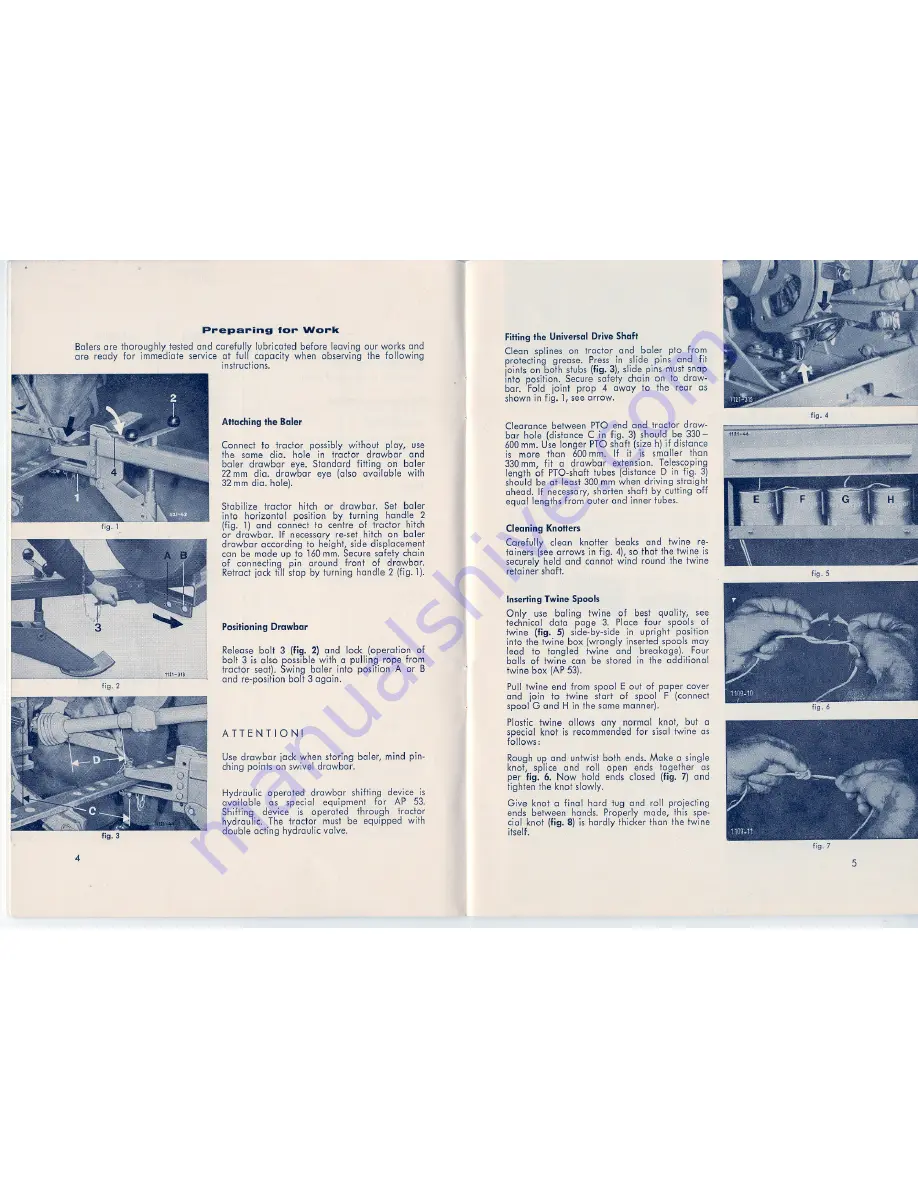

Attaching the Baler

Connect to traetor possibly without play, usa

the same dia. hole in traetor

drawbar

and

baler drawbar

are. Standard

fitting on baler

22 mm dia. drawbar

eye (also available

with

32 mm dia. hole).

Stabilize traetor

hitch or drawbar.

Set baler

info horizontal

position by turning handle 2

(fig. 1) and conneet to tantra of traetor hitch

or drawbar.

If necessary re-set hitch on baler

drawbar according to height, side displacement

can be made up to 160 mm. Secure safety chain

of conneeting pin around

front of drawbar.

Retraet jack till stop by turning handle 2 (fig. 1).

Positioning Drawbar

Release bell 3 (fig. 2) and lock (operation of

bell 3 is also possible with a puUing rope from

traetor seal). Swing baler info position A or B

and re-positi,on bell 3 again.

ATTENTION!

Usa drawbar jack when storing baler, mind pin-

thing po,ints on swivel drawbar.

Hydraul,ic operated

drawbar shifting device is

ava,i:lable as specia,! equipment

tor

AP 53.

ShiUing device

is opera ted through

traetor

hydraul,ic. The traetor

must be equipped with

double aeting hydraulic valve.

1

FiHingthe Universal Drive Shaft

Clean splines on traetor and baler pto from

proteeting grease. Press in slide pins and fit

joints on both stubs (fig. 3), slide pins must snap

info position. Secure safety chai,n on to draw-

bar. Fold joint prop 4 away to the rear as

shown in fig. 1, see arrow.

Clearance between pro

end and traetor draw-

bar hole (distance C in fig. 3) should be 330-

600 mm. Usa Ionger pro shaft (size h) if distance

is more thon 600 mm. If i.t is smaller thon

330 mm, fit a drawbar

extension. Telescoping

length of PTO-shaft tubes (distance D in fig. 3)

should be at least 300 mm when driving straight

ahead. If necessary, shorten shaft by cutting off

equallengths

from euter and inner tubes.

Cleaning KnoHers

Carefully clean knotter beaks and twine re-

tainers (see arrows in fig. 4), so thaI the twine is

securely held and cannot wind round the twine

retainer shaft.

~

"

Inserting Twine Spools

Only usa baling

twine of best quality, see

technical data

page 3. Place tour spools of

twine (fig. 5) side-by-side in upright position

info the twine box (wrongly inserted spools may

lead to tangled

twi.ne and

breakage).

Four

balls of twine can be stored in the additional

twine box (AP 53).

Pull twine end from spool E out of paper cover

and

join to twine start of spool F (conneet

spool G and H in the same manner).

Plastoietwine allows any normal knot, but a

special knot is recommended tor si,sal twine as

fellows :

Rough up and untwist both ends. Make a single

knot, spließ and roll open ends together

as

per fig. 6. Now hold ends closed (fig. 7) and

fighten the knot slowly.

Give knot a final hard lug and roll proieeting

ends between hands. Properly made, this spe-

cial knot (fig. 8) is hardly thicker thon the twine

itself.

I-

fig.4

fig. 5

fig. 6

fig, 7

5

Summary of Contents for AP 38

Page 1: ......