Adjuslmenl

of Ram

Ram 1 (fig.

18) is guided in the bole chamber

by rollers. Its position

on forward

end back-

ward

stroke

is assured by two

stee,1 angle

guides, one situated on bollom

of knife side,

the second one on top of opposite side in bole

chamber. It has 10 be checked regulari,ly if rom

is running free of pier,

if not guide angle 2

has to be adjusted accordingly:

Remove gu'ide plate from feed fable.

Loosen fixing bolls 3 (5 pe.) fig. 18, adjust angle

guide

2 with

bolts 4 up against

rom roller,

repeat until parallelism

of guide angles is as-

sured. Fix bolts 3 end lock adjusting bolt 4.

IMPORTANT:

After rom adjustment

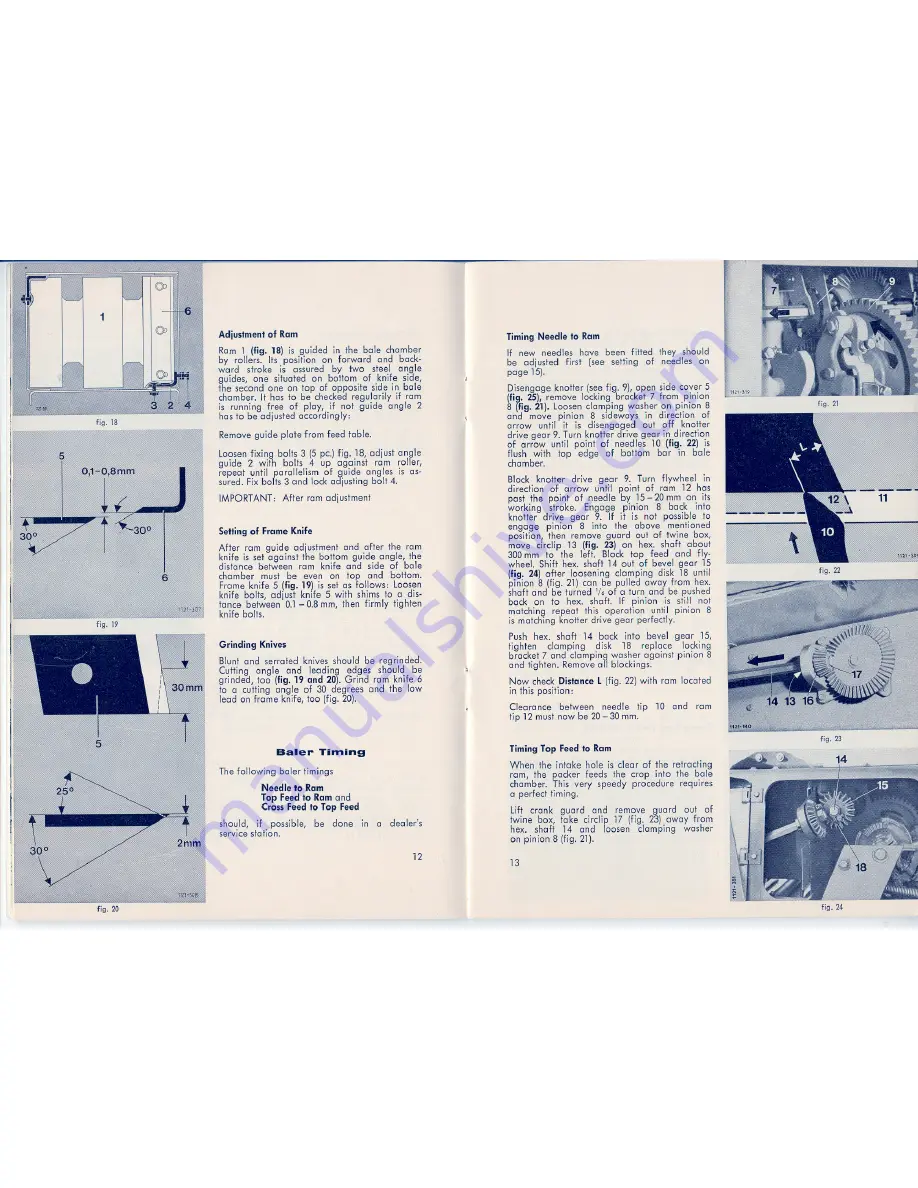

Setting of Frame Knife

After

rom guide adjustment end after the rom

knife is set against the bollom guide angle, the

distance between rom knife end side of bole

chamber

must be even on top

end

bollom.

Frame kni,fe

5 (fig. 19) is set as fol,lows: Loosen

knife bolts, adjust knife 5 with shims to a dis-

tance between 0.1 - 0.8 mm, then firmly fighten

knife bolts.

Grinding

Knives

Blunt end serrated knives should be regrinded.

Culling

angle

end

leading

edges should

be

grinded, 100 (fig. 19 and 20). Grind rom knife 6

to a cutting angle of 30 degrees end the low

lead on frame knife, too (fig. 20).

Baler

Timing

The following

baler timings

Needle 10 Ram

Top Feed 10 Ram end

Cross

Feed 10 Top Feed

should,

if

possible,

be

done

in

servi,ce station.

a

dealer's

12

fig. 20

Timing Needle 10 Ram

If new needles have been fitted

they shou,ld

be adjusted

first

(see setting

of

needles on

page 15).

Disengage knotter (see fig. 9), open side cover 5

(fig. 25), remove locking bracket 7 from pinion

8 (fig.

21). Loosen olamping washer on pinion 8

end move pinion

8 sideways in direction

of

arrow

until

it is disengaged

out off

knotter

drive geer 9. Turn knotter drive geer in direction

of arrow until point of needles

10 (fig.

22) is

flush with

top

edge of

bollom

bar

in bole

chamber.

~

Block knoller

drive geer

9. Turn flywheel

in

direction

of arrow

until point of rom 12 has

post the point of needle by 15 - 20 mm on its

working

stroke.

Engage

pinion

8 back

info

knotter

drive geer 9. If it is not possible to

engage

pi nion

8 info

the above

mentioned

position, then remove guard out of Iwine box,

move

circlip .13 (fig.

23) on hex. shaft about

300 mm to the left. Block top feed

end fly-

wheel. Shift hex. shaft 14 out of bevel geer 15

(fig. 24) eHer loosening oIamping disk 18 unti,1

pinion 8 (fig. 21) can be pul.led away from hex.

shaft end be turned '/6 of a turn end be pushed

back on to hex. shaft. If pinion

,is sti,111

not

ma,tching repeat ,this operation

un~il pinion

8

is matching knoller dnive geer perfectly.

Push hex. shaft 14 back info bevel geer 15,

fighten

clamping

disk

18

replace

locking

bracket 7 end clamping washer aga,inst pinion 8

andtighten.

Remove oll blockings.

Now check

Dislance

L (fig. 22) with rom located

in this position:

Clearance

between

needle

tip

10 end

rom

tip 12 must now be 20

-

30 mm.

Timing Top Feed 10 Ram

When the intake

hole is dear of the retracting

rom, the packer feeds the crop info the bole

chamber. This very speedy procedure requires

a perfecttiming.

Lift

crank

guard

end

remove

guard

out

of

twi.ne

box, take circlip 17 (fig. 23) away from

hex. shaff

14 end

loosen

clamping

washer

on pinion 8 (fig. 21).

13

fig.22

fig. 23

fig.24

Summary of Contents for AP 38

Page 1: ......