30

IOM-131

MODEL: LS-14

REV: F

13839 West Bellfort Street, Sugar Land, TX 77498

welker.com

Service Department 281.491.2331

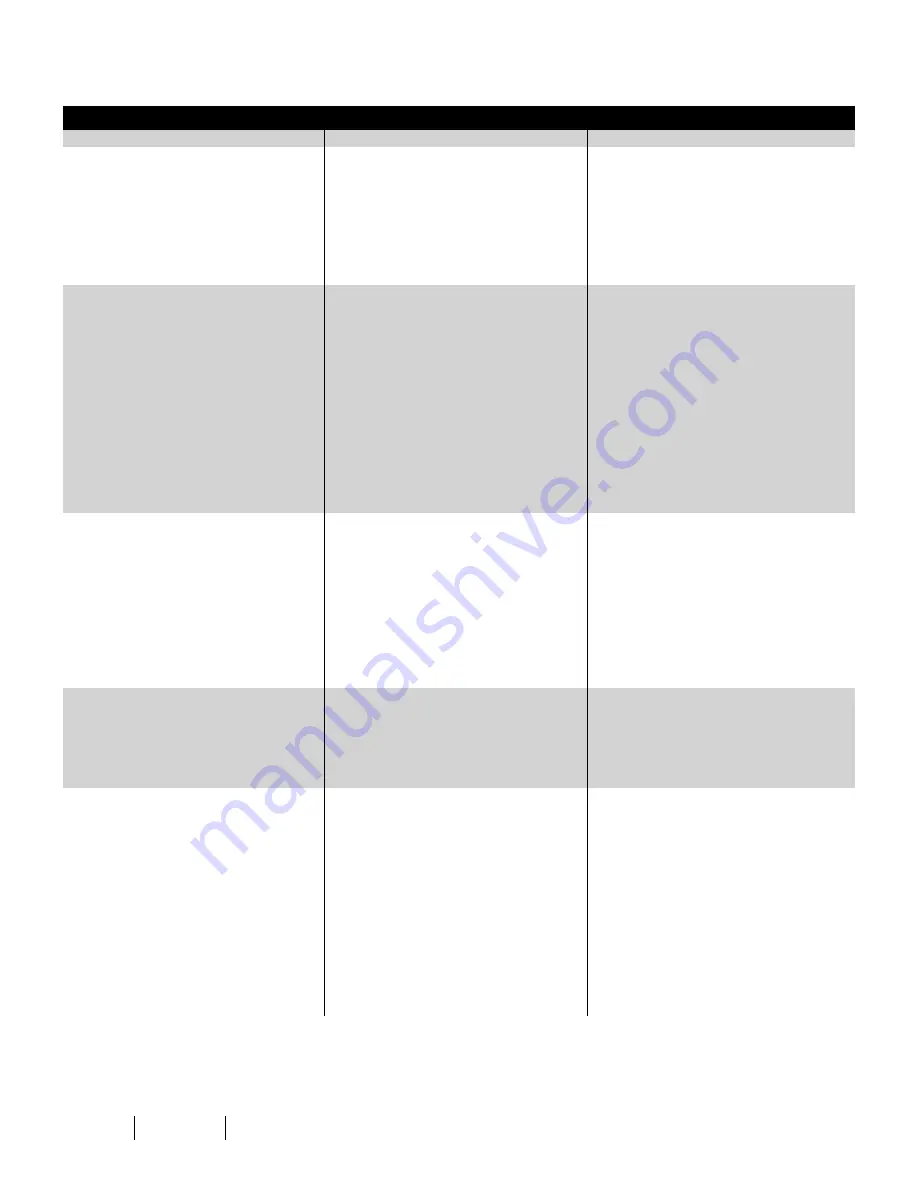

3.3 Troubleshooting

Table 3: LS-14 Troubleshooting

Issues

Possible Causes

Solutions

The LS-14 will not fill to 80%.

Pre-charge pressure may not be relieving

back to the inert gas supply tank.

Ensure that valve A and valve C, if

applicable, on the inert gas supply tank

are open during composite sampling to

allow pressure to be relieved back to the

inert gas supply tank from the pre-charge

side as product enters the LS-14 (

).

The LS-14 is filling too quickly.

Pre-charge pressure may not be supplied

to the LS-14 at the appropriate pressure.

The sampler may be set at a faster

sampling frequency than desired.

Apply additional pre-charge pressure to

the LS-14 until the pre-charge pressure

reaches 50–100 psig above pipeline

operating pressure, not to exceed the

maximum allowable operating pressure

of the equipment.

Adjust the PLC to sample at the desired

rate. Ensure that the calculations used to

determine the sample frequency are

correct (

The tracker magnet is not moving.

The hydraulic or pneumatic supply may

not be directed below the actuator

piston.

Sample is leaking from the receiver

cylinder.

Ensure that the mixer lever/button is

tubed to the bottom of the actuator

cylinder.

Ensure that purge/return valve D is closed.

Check for leaks between the sampler and

the receiver cylinder and repair as

necessary.

The burst disc on the product side

of the LS-14 is leaking.

The lifespan of the burst disc may have

been exceeded.

Replace the burst disc. A more frequent

preventative maintenance schedule may

be required for the burst disc. Do not

exceed 80% volume in the LS-14 to avoid

overpressurizing the receiver cylinder.

The burst disc on the pre-charge

side of the LS-14 is leaking.

The valve on the pre-charge side of the

LS-14 may be closed.

The lifespan of the burst disc may have

been exceeded.

Ensure that valve A and valve C, if

applicable, on the inert gas supply tank

are open during composite sampling to

allow pressure to be relieved back to the

inert gas supply tank from the pre-charge

side as product enters the LS-14 (

).

Replace the burst disc. A more frequent

preventative maintenance schedule may

be required for the burst disc.