Pay special attention to the area just below the top on

powder coated frames. This area is subject to salt build

up from salty condensation and sea spray. It is also

frequently overlooked when the boat is washed and will

not be rinsed by the rain. Consequently, the powder

coating near fasteners and hardware mounted just

below the top is more likely to be attacked by the salt

and become corroded than the exposed areas on the

structure. Make sure the aluminum in this area is

washed frequently with soap and water and rinsed

thoroughly. Pay particular attention to places where the

top material contacts the frame.

Once a month check the entire frame for damaged

powder coating and corrosion around fasteners and

hardware. Nicked or badly scratched powder coating can

be sanded and touched up with enamel paint. Corrosion

around fasteners will have to be sanded, then touched

up with paint. The fasteners will require fiber washers

and sealing with caulk or a teflon based sealer to isolate

the fastener from the aluminum and prevent damage to

the paint or powder coating when the fastener is

installed. Periodically applying automotive or boat wax to

the powder coating will provide additional protection

from the harsh effects of saltwater.

Always repair scratches, nicks and corroded areas in

powder coating as soon as possible. Corrosion left

unaddressed will lift the powder coating allowing

moisture to travel between the powder coating and the

aluminum causing the corrosion to spread below the

coating and damage the aluminum.

If excessive chipping and peeling occurs, it could be an

indication of an electrical fault in the boat or aluminum

fabrication. You should contact a qualified marine

electrician to inspect your boat immediately and correct

the problem if you suspect that your boat may have a

fault in the aluminum frame. You should also contact

Wellcraft Customer Service.

Note: Boats that are towed behind larger vessels

require special attention to the aluminum

hardware. The salt spray, salty steam, and

chemicals in exhaust gases are

particularly corrosive and will eventually

penetrate and damage the surface of

anodized or powder coated aluminum. It is

imperative that the boat and the

aluminum are cleaned thoroughly at the

completion of each trip or at the end of

each day on long cruises to reduce

accelerated deterioration of the anodizing

or powder coating and premature

corrosion to the aluminum.

Note: You should contact Wellcraft Customer

Service before making any modifications

to aluminum fabrications. Unauthorized

modifications can void the warranty.

Chrome Hardware

Use a good chrome cleaner and polish on all chrome

hardware.

Acrylic Plastic Glass

Acrylic glass scratches easily. Never use a dry cloth or

glass cleaning solutions on acrylic. Use a soft cloth and

mild soap and water for routine cleaning. Solvents and

products containing ammonia can permanently damage

acrylic plastic glass.

Fine scratches can be removed with a fine automotive

clear coat polishing compound. A coat of automotive or

boat wax is beneficial to protect the surface.

Do not use the following on acrylic glass:

Abrasive cleaners

Acetone

Solvents

Alcohol

Glass cleaners

Cleaners containing ammonia

10.2 Upholstery, Canvas and Enclosures

Vinyl Upholstery

The vinyl upholstery used on the exterior seats and

bolsters, and for the headliner in the cabin should be

cleaned periodically with soap and water. Any stain, spill

or soiling should be cleaned up promptly to prevent the

possibility of permanent staining. When cleaning, always

rub gently. Avoid using products containing ammonia,

powdered abrasive cleaners, steel wool, strong solvents,

acetone and lacquer solvents or other harsh chemicals

as they can cause permanent damage or shorten the life

of vinyl. Never use steam heat, heat guns or hair dryers

on vinyl.

Stronger cleaners, detergents and solvents may be

effective in stain removal, but can cause either

immediate damage or slow deterioration. Lotions, sun

tan oil, waxes and polishes, etc., contain oils and dyes

that can cause stiffening and staining of vinyls.

The following are typical stains and cleaning tips

for vinyl:

• Dry soil, dust and dirt - Remove with a soft cloth.

• Dried on dirt - Wash with a soft cloth dampened

with water.

• Variations in surface gloss - Wipe with a water

dampened soft cloth and allow to air dry.

54

Summary of Contents for 180 Sportsman

Page 2: ...2...

Page 4: ...4...

Page 7: ...180 FISHERMAN SPECIFICATIONS 7...

Page 8: ...180 SPORTSMAN SPECIFICATIONS 8...

Page 9: ...202 FISHERMAN SPECIFICATIONS 9...

Page 10: ...212 FISHERMAN SPECIFICATIONS 10...

Page 18: ...18...

Page 39: ...SAFETY LABELS 2601 1124 39...

Page 40: ...180 FISHERMAN 180 SPORTSMAN CAPACITY LABELS 40...

Page 41: ...202 212 FISHERMAN CAPACITY LABELS 41...

Page 61: ...Appendix A SCHEMATICS 180 FISHERMAN INSTRUMENT PANEL 61...

Page 62: ...Appendix A SCHEMATICS 180 SPORTSMAN INSTRUMENT PANEL 62...

Page 63: ...Appendix A SCHEMATICS 202 212 FISHERMAN INSTRUMENT PANEL 63...

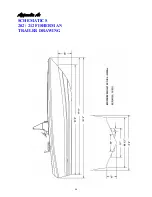

Page 68: ...Appendix A SCHEMATICS 180 FISHERMAN 180 SPORTSMAN TRAILER DRAWING 68...

Page 69: ...Appendix A SCHEMATICS 202 212 FISHERMAN TRAILER DRAWING 69...

Page 70: ...Appendix A SCHEMATICS 180 FISHERMAN OVERHEAD LAYOUT 70...

Page 71: ...Appendix A SCHEMATICS 180 SPORTSMAN OVERHEAD LAYOUT 71...

Page 72: ...Appendix A SCHEMATICS 202 FISHERMAN OVERHEAD LAYOUT 72...

Page 73: ...Appendix A SCHEMATICS 212 FISHERMAN OVERHEAD LAYOUT 73...

Page 77: ...MAINTENANCE LOG 77...

Page 78: ...MAINTENANCE LOG 78...

Page 80: ...Appendix D BOAT ACCIDENT REPORT 80...

Page 81: ...81...

Page 87: ...Appendix F TROUBLESHOOTING GUIDE 87...

Page 88: ...TROUBLESHOOTING GUIDE 88...

Page 89: ...TROUBLESHOOTING GUIDE 89...

Page 90: ...TROUBLESHOOTING GUIDE 90...

Page 91: ...TROUBLESHOOTING GUIDE 91...