3.3

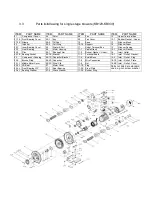

Parts list/drawing for single stage blowers (KB129-KB939)

ITEM

PART NAME

ITEM

PART NAME

ITEM

PART NAME

ITEM

PART NAME

01

Compressor Cover

04

Rotor

08

Fan

12

Upper Terminal Box

01-1E Front Bearing Cover

04-1

Key

09

Fan Cover

12-1

Rubber Gasket

(

Upper

)

01-2E Nipple

04-2

Oil Seal

10

Base

13

Silencer Mesh

02

Impeller

04-3

Felt Ring

10-1E Support

14

Silencer Foam

02-1

Inner Bearing Cover

05

Stator & Coil

11

Under Terminal Box

15

Silencer Casing

02-2

Front Bearing

06

Motor Housing

11-1

Cable Gland

15-1

Silencer Gasket

02-3

Disc

06-1

Sponge Filler

11-2

Rubber Gasket

(

Under

)

16

Inlet / Outlet

02-1E Bearing Socket

06-1E Bracket

11-3

Terminal Board

16-1

Inlet

(

Outlet

)

Gasket

03

Compressor Housing

06-1S Capacitor Bracket

11-4

Board Base

16-3

Inlet

(

Outlet

)

Plug

03-3

Bronze Ring

06-2S Capacitor

11-5

Wire Connection

16-1E Inlet

(

Outlet

)

Plate

03-1L Middle Motor Cover

06-3S Steel Clip

11-6

Nut

16-2E Inlet

(

Outlet

)

Cover

03-2L VA-Seal

07

Motor Cover

11-1E Plug

Parts not listed are standard

ones, e.g.nut,screw, washer

03-3L Front Bearing WP

07-1

Rear Bearing

11-2E Steel Plate

03-4L Bearing Washer

07-2

Wave Washer

11-3E Rubber Ring