2.2

Installation continued

L)

Since the pressure and current of the blower are in direct proportion, it is

necessary to install a pressure relief valve at the air suction/extraction port

to avoid overcurrent failure of the motor. The pressure relief valve listed

below can used in both compressor and vacuum applications.

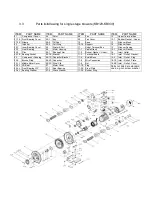

Mounting:

Outline:

Type

Thread

Interval

RV-01

PF-

1 1/4 “

0 ~ 300mbar

RV-02

PF-

1 1/4 “

0 ~ 600mbar

M)

Pressure and air friction can easily build up heat around the outlet of the

blower. To lead away the heat, an iron pipe at minimum 1 meter is thus

needed to be connected to the outlet.

N)

On the discharge side, the cover, impeller and silencer housing must not

come into contact with flammable materials (i.e. wood)

O)

The flow noise is reduced by build-in silencers. In the case of free air

intake or exhaust, the noise can be further reduced by attaching additional

silencers. In order to reduce noise emission even further, these units

should not be attached to components that conduct or radiate sound (such

as thin walls, metal plates etc.). If necessary provide intermediate sound-

absorbing layers.